Description

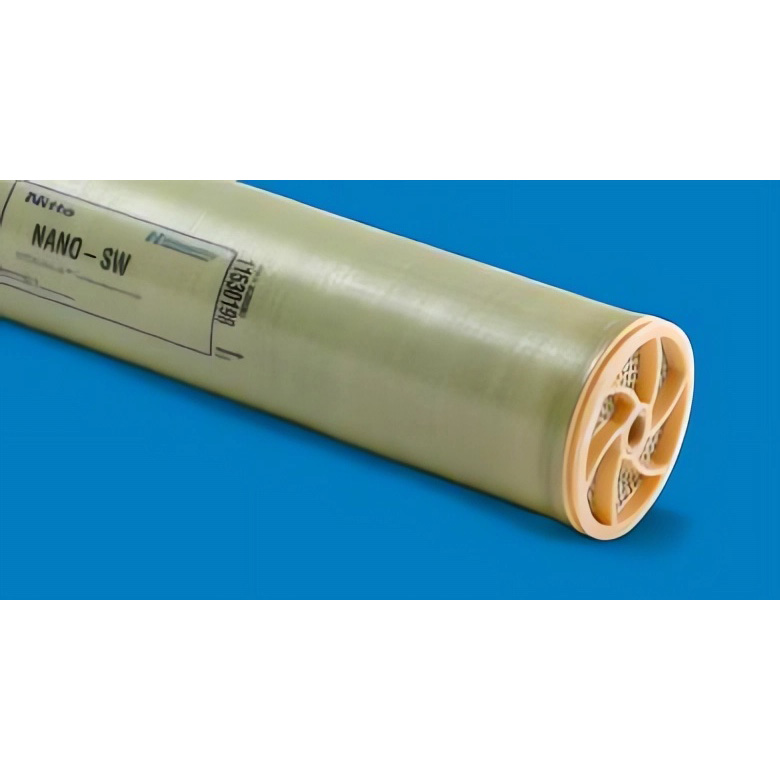

SanRO and SanRO-HS-4 HS-8 4×40″ and 8×40″ USP reverse osmosis membrane elements Hydranautics

Introducing Hydranautics’ revolutionary SanRO® Membrane and SanRO®-HS USP-grade reverse osmosis elements, designed specifically to meet the production needs of the pharmaceutical and industrial industries. With our advanced membrane technology and Hydranautics’ experience in the market, this USP-grade reverse osmosis solution offers a heat-disinfecting membrane designed to disinfect at 85 °C (85 °F). These membranes are highly permeable and have high rejection, energy saving, high flux and low energy cost.

Industries where SanRo membrane is applied:

- Production of purified water in pharmaceutical and medical processes

- Biotechnology products

- Food and beverage production

- Semiconductor manufacturing

Hydranautics SanRO® Membrane and SanRO®-HS USP elements ensure excellent removal of bacteria, viruses and dissolved solids, making it the ideal choice for critical applications in the production of purified and ultrapurified water. In addition, its innovative design allows for greater resistance to contamination and extended service life, reducing maintenance costs and ensuring efficient and reliable operation.

Benefits of SanRo membrane

- Decrease of bacterial endotoxins and microorganisms

- Manufacture of products for ophthalmic and inhalation use.

- Reduction of total dissolved solids (TDS), total organic carbon (TOC) and colloids in high purity water.

- Elimination of algae, fungi, molds, yeasts and bacteria expressed in “colony forming units” (CFU)

- Extraction of bacteria from cell walls of polysaccharide compounds.

- Controlling microbial growth by reducing nutrients

- Ultrapure water of electronic and semiconductor quality

- Water used in the manufacture of cosmetics

- Nutraceuticals production

- Food and beverage processing

- Rinsing or washing of containers

- Manufacture of ultrapure water or PW (Purified Water)

- Wine dealcoholization

- Substitution of distillation systems, resulting in lower energy consumption and costs.

SanRo membranes available:

SanRO: Membranes for high efficiency USP water purification systems, used at operating temperatures up to 45°C.

SanRO-HS: Thermo-sanitizable version (can be disinfected by heating) at 85°C.

SanRO-HS2: A HS variant with higher flow and slightly lower rejection.

All SanRO® models are available in 4″ and 8″ diameters.

| Type of membrane | Description of the membrane | Membrane performance | Reverse osmosis system performance** | |||

| Permeate Flow and Rejection | Applied Pressure | Permeate TDS, PPM | ||||

| GPD (m³/day) | of Nominal Rejection | |||||

| 4040 (4×40) | 8040 (8×40) | |||||

| SanRO HS | Heat disinfection, High rejection composite | 2,200 (8.3) SanRO-HS-4 | 10,000 (37.9) SanRO-HS-8 | 99.7%

(99.4% min.) |

161 psig (1.11 MPa) | 7.8 ppm |

| SanRO HS2 | Heat disinfection, High flow, high rejection composite | 3,000 (11.4) SanRO®-HS2-4 | 14,000 (53.0) SanRO-HS2-8 | 99.6%

(99.4% min.) |

124 psig (0.85 MPa) | 10.6 ppm |

* Test conditions: Element performance is at 225 psig (1.55 MPa), 1500 mg/l NaCl, 15% recovery, 77°F (25°C).

** Applied pressure and permeate TDS are projected values for a 2:2:1 matrix system operating at an average flow rate of 15 gfd (26 lmh) with a 500 mg/l TDS (NaCl) feed, 80% recovery, pH 7, and 77°F (25°C).

SanRo membrane characteristics

- Maximum applied pressure 600 PSIG (4.14 MPa)

- Maximum chlorine concentration < 0.1 ppm

- Maximum operating temperature 131 °F (55 °C)

- Maximum sanitizing or disinfection temperature 185 °F (85 °C)

- Maximum sanitizing pressure 25 psig (0.17 MPa)

- Operating pH range 2.0 – 10.0

- Cleaning pH range 1.0 – 12.0

- Maximum pressure drop for a vessel 60 PSIG (0.41 MPa)

It differentiates itself from competitors thanks to its ability to meet the strict quality and safety standards of the pharmaceutical industry and the stringent demands of sanitation and disinfection. Hydranautics’ SanRO® Membrane and SanRO®-HS USP elements have been certified by NSF61 and NSF419, demonstrating compliance with public drinking water regulations and ensuring efficacy in high purity applications.

By choosing Hydranautics’ SanRO® Membrane and SanRO®-HS USP elements, users can rely on a high-performance solution that will allow them to optimize their processes and ensure the quality and safety of their final products.