Description

Ultrafiltration HYDRAcap MAX: The ultimate solution in ultrafiltration and water purification for industry.

Discover the revolutionary HYDRAcap MAX Ultrafiltration system, specially designed for drinking water treatment and industry that seeks to improve water quality in industrial processes, housing, hotels and places that require compliance with drinking water standards or water reuse. With our advanced 0.08 micron PVDF TIPS membrane technology, we guarantee superior water purification performance, enabling greater savings and efficiency in your operations.

HYDRAcap® MAX is an ultrafiltration technology using PVDF hollow fiber. Pressurized hollow fiber modules are suitable for a wide range of applications, either as final treatment or as pretreatment for reverse osmosis (RO) and nanofiltration (NF).

Applications:

- Industrial or municipal wastewater

- Seawater pretreatment

- Surface and groundwater treatment

Benefits and key features of HydraCap Ultrafiltration membranes:

- High recovery and low space requirements: Thanks to its optimized membrane area and innovative cleaning regimes, HYDRAcap MAX offers a high water recovery rate and a smaller footprint in your facility.

- High-strength PVDF membrane: Our PVDF membranes minimize fiber breakage rate, ensuring consistently superior filtration quality. This allows reverse osmosis (RO) and nanofiltration (NF) systems to operate with higher flow rates and fewer intervals between cleanings.

- No need for backwash pump or backwash : The HYDRAcap MAX system does not require a backwash pump. Physical cleaning is performed with pressurized air, thanks to a unique and patented air diffuser design.

- Exclusive web simulator: Hydranautics offers access to an innovative web simulator to design HYDRAcap MAX systems easily and efficiently. This simulator is used by thousands of engineers to design and understand the complete ultrafiltration unit.

- HYDRAcube system: A pre-engineered and standardized frame system where all module connections are integrated into a single head piece. This allows HYDRAcap MAX modules to operate in robust and space-optimized conditions.

Differentiate your project with HYDRAcap MAX Ultrafiltration, the leading solution in the market for water purification in drinking water treatment or water reuse processes. Don’t wait any longer to experience the benefits that this technology can bring to your business. Purchase the HYDRAcap MAX system today and take water quality in your industry or hotel to a new level!

Available ultrafiltration membranes:

Capillary ultrafiltration module HYDRAcap MAX 40

Performance:

Filtration flow rate: 7.5 – 24.4 gpm (1.7 – 5.5 m3/h)

Turbidity of the filtrate: ≤ 0.10 NTU

Bacteria removal: ≥ 4 log

Type

Configuration: Capillary ultrafiltration module

Membrane polymer: TIPS PVDF

Nominal area of membrane: 52 m2 (560 ft2)

Fiber dimensions: ID 0.024″ (0.6 mm), OD 0.047″ (1.2 mm)

Pore size: 0.08 microns

Application data

Typical filtrate flow range: 20 – 65 gfd (34 – 110 l/m2/h)

Maximum applied feed pressure: 5.0 bar (73 psig)3

Maximum transmembrane pressure: 2.0 bar (30 psig)

Chlorine instantaneous tolerance: 5000 ppm4

Maximum chlorine exposure: 1,000,000 ppm – hour

Maximum feed turbidity: 300 NTU5

Maximum operating temperature: 104 °F (40 °C)

Operating range pH: 2.0 – 11.0

Cleaning pH range: 1.0 – 13.0

Operating mode: Outside to inside filtration / Dead-end or cross-flow mode

Typical process conditions

Aeration rate: 12.3 – 15.4 m3/h (7.3 – 9.1 acfm)

Aeration duration: 120 – 240 seconds

Frequency of aeration: Once every 20 – 60 minutes

Frequency of maintenance cleaning: 1 – 3 times daily

Duration of maintenance cleaning: 20 – 30 minutes

Disinfection chemicals: NaOCl, ClO2 or NH2Cl

Cleaning chemicals: NaOH, HCl, H2SO4 or citric acid

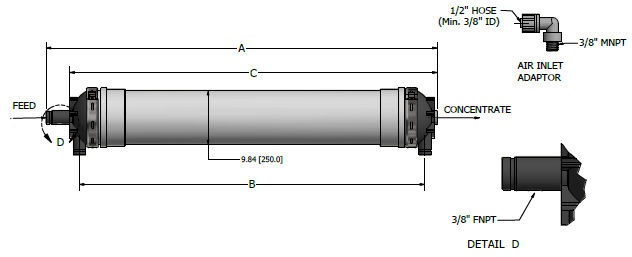

A, inches (mm) |

B, inches (mm) |

C, inches (mm) |

Pipe connections |

Dry weight |

Wet weight |

|---|---|---|---|---|---|

53.74 (1364.9) |

44.70 (1135.5) |

49.50 (1257.3) |

2″ Victaulic |

90 lbs (41 kg) |

161 lbs (73 kg) |

Capillary Ultrafiltration Module HYDRAcap MAX 60

Performance

Filtration flow rate: 11.7 – 37.9 gpm (2.7 – 8.6 m3/h)

Turbidity of the filtrate: ≤ 0.10 NTU

Bacteria removal: ≥ 4 log

Configuration Type: Capillary Ultrafiltration Module

Membrane polymer: PVDF TIPS

Nominal membrane area: 840 ft2 (78 m2)

Fiber dimensions: ID 0.024″ (0.6 mm), OD 0.047″ (1.2 mm)

Pore size: 0.08 microns

Application Data

Typical filtrate flow range: 20 – 65 gfd (34 – 110 l/m2/h)

Maximum supply pressure applied: 73 psig (5.0 bar)3

Maximum transmembrane pressure: 30 psig (2.0 bar)

Instantaneous chlorine tolerance: 5000 ppm4

Maximum exposure to chlorine: 1,000,000 ppm-hrs

Maximum feed turbidity: 300 NTU5

Maximum operating temperature: 104 °F (40 °C)

Operating pH range: 2.0 – 11.0

Cleaning pH range: 1.0 – 13.0

Mode of operation: Outdoor to Indoor Filtration / Deadflow or Crossflow Mode

Typical Process Conditions

Aeration rate: 7.3 – 9.1 acfm (12.3 – 15.4 m3/h)

Aeration duration: 120 – 240 seconds

Frequency of aeration: Once every 20 – 60 minutes

Frequency of maintenance cleaning: 1 – 3 times daily

Maintenance cleaning time: 20 – 30 minutes

Chemical disinfection: NaOCl, ClO2 or NH2Cl

Cleaning chemicals: NaOH, HCl, H2SO4 or Citric Acid

A inches (mm) |

B inches (mm) |

C inches (mm) |

Pipe connections |

Dry weight |

Wet weight |

|---|---|---|---|---|---|

72.15 (1832.6) |

63.11 (1602.9) |

67.90 (1724.7) |

2″ Victaulic |

115 lbs (52 kg) |

220 lbs (100 kg) |

Capillary ultrafiltration module HYDRAcap MAX 80

Performance

Filtration flow rate: 15.7 – 51.0 gpm (3.6 – 11.6 m3/h)

Turbidity of the filtrate: ≤ 0.10 NTU

Bacteria removal: ≥ 4 log

Configuration type: Capillary Ultrafiltration Module

Membrane polymer: PVDF TIPS

Nominal membrane area: 1130 ft2 (105 m2)

Fiber dimensions: ID 0.024″ (0.6 mm), OD 0.047″ (1.2 mm)

Pore size: 0.08 microns

Application data

Typical filtrate flow range: 20 – 65 gfd (34 – 110 l/m2/h)

Maximum supply pressure applied: 73 psig (5.0 bar)3

Maximum transmembrane pressure: 30 psig (2.0 bar)

Instantaneous chlorine tolerance: 5000 ppm4

Maximum exposure to chlorine: 1,000,000 ppm-hrs

Maximum feed turbidity: 300 NTU5

Maximum operating temperature: 104 °F (40 °C)

Operating pH range: 2.0 – 11.0

Cleaning pH range: 1.0 – 13.0

Mode of operation: Outdoor to Indoor Filtration / Deadflow or Crossflow Mode

Typical process conditions

Aeration rate: 7.3 – 9.1 acfm (12.3 – 15.4 m3/h)

Aeration duration: 120 – 240 seconds

Frequency of aeration: Once every 20 – 60 minutes

Frequency of maintenance cleaning: 1 – 3 times daily

Maintenance cleaning time: 20 – 30 minutes

Chemical disinfection: NaOCl, ClO2 or NH2Cl

Cleaning Chemicals: NaOH, HCl, H2SO4 or Citric Acid

A, inches (mm) |

B, inches (mm) |

C, inches (mm) |

Pipe connections |

Dry weight |

Wet weight |

|---|---|---|---|---|---|

92.15 (2340.6) |

83.11 (2110.9) |

87.90 (2232.7) |

2″ Victaulic |

135 lbs (62 kg) |

260 lbs (118 kg) |

Certifications:

NSF61, NSF419 (US LT2ESWTR – Public Drinking Water Compliance)

1. Typical module performance for most feedwaters.

2. The limitations shown here are for general use. Values can be more conservative for specific projects to ensure the best performance and longest membrane life.

3. AT ≤20°C. 58 psi (4 bar) between 21 – 30°C. 44 psi (3 bar) between 31 – 40°C.

4. For 60 minutes or less.

5. Higher values can be treated. Consult Hydranautics technical personnel.

Note: Hydranautics also offers HYDRAcap MAX 80-NON, which is a dummy module without sealing or fiber. Hydranautics believes that the information and data contained in this document is accurate and useful. The information and data are offered in good faith, but without warranty, as the conditions and methods of use of our products are beyond our control. Hydranautics assumes no liability for results obtained or damages incurred through the application of the information and data presented. It is the user’s responsibility to determine the suitability of Hydranautics products for the user’s specific end uses. 9/1/20

Ultrafiltration Membrane: The Revolutionary Solution for Industrial and Municipal Water Treatment

The Ultrafiltration Membrane presents a state-of-the-art solution for water treatment in industrial and municipal applications, designed to overcome the most challenging challenges in the purification process.

This innovative membrane demonstrates its effectiveness by incorporating ultrafiltration technology that allows precise and efficient removal of suspended solids, bacteria and viruses, significantly reducing water turbidity. Thus, you will get high quality purified water at all times.

The benefits of the ultrafiltration membrane do not stop there. This advanced system also provides high performance in terms of water flow and durability, which translates into lower operating and maintenance costs. The effectiveness of the Ultrafiltration membrane also reduces the dependence on chemicals used in water treatment, making it more environmentally friendly.

Ideal for the industrial and municipal sectors, the ultrafiltration membrane not only complies with strict regulations on water quality, but also guarantees a reliable and safe water supply over time.

The ultrafiltration membrane is the revolutionary solution that will transform your water treatment processes, giving you the best quality and most reliable results every time. Try HydraCap Max Ultrafiltration Membrane today and discover how it can dramatically improve your water quality in an instant.