Description

Silica or silica sand. What is it?

Silica sand is a compound resulting from the combination of silica with oxygen. Its chemical composition consists of one silica atom and two oxygen atoms, forming a very stable molecule: SiO₂.

This molecule is insoluble in water and is found in nature in the form of quartz. If the quartz is crystallized it is called Rock Crystal.

It belongs to the silicate class and to the trigonal crystalline system. This mineral is very rich in varieties, which can be grouped into Macrocrystalline, with crystals well visible to the naked eye, and Cryptocrystalline, formed by microscopic crystals.

What is silica sand used for in water treatment?

The industrial uses of silica sand derive from its important physical and chemical properties, especially its hardness, chemical resistance, high melting point, piezoelectricity, pyroelectricity and transparency.

The sands are mainly used:

- As a filter bed for water purification and potabilization (for the retention of very small flocs that are not separated by decantation).

- Due to their hardness, they are used for the manufacture of lyes, industrial abrasives and sandblasting.

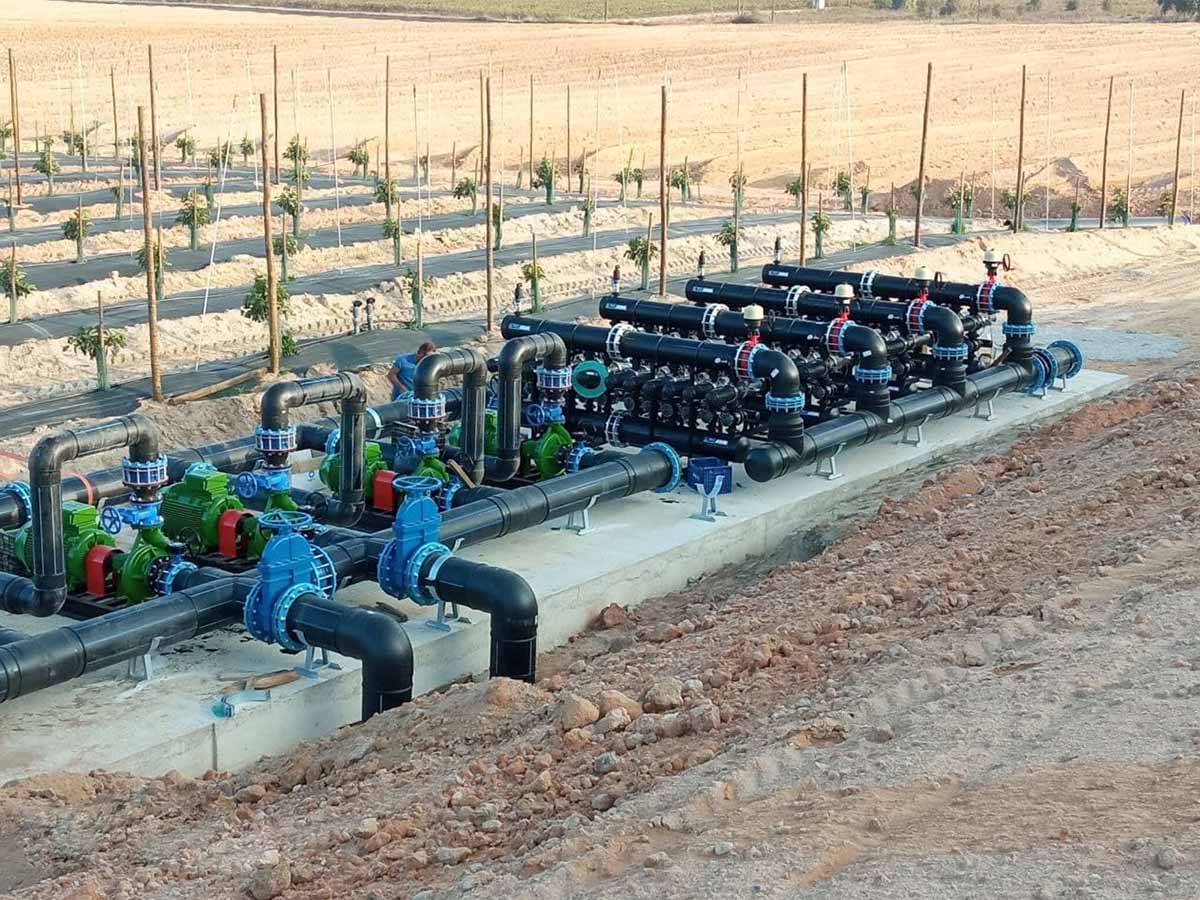

Our silica sand for water purification is especially suitable for applications in drinking water treatment systems, wastewater, swimming pools, aquariums and industrial processes. In addition, it is wear-resistant, non-toxic and non-flammable, making it safe and easy to handle.

Silica sand is a durable, low-maintenance filter media that can be used in gravity or pressure filtration systems. Being a natural product, it is not only environmentally friendly, but also highly effective in removing impurities, making it an economical and efficient alternative to other filter media.

In summary, our silica sand for water purification is a reliable and cost-effective solution for improving water quality in a variety of applications. With high filtration performance, durability and safety, it is the perfect choice for any water treatment system.

It is a very important raw material in the composition of detergent formulas, paints, concretes and special mortars, and is the basic raw material for obtaining silicon, as well as the basis for the manufacture of silica refractories and model sands, due to its high melting point.

How is silica sand composed?

It is mainly composed of quartz, more specifically or mostly white quartz, this mineral is considered the most abundant in the earth, besides quartz it contains 5% of other minerals.

Impurities are usually mineral in nature and, like quartz, resist transport and weathering processes.

Chemical analysis |

Composition |

SiO₂ |

98.5% |

Fe₂O₂O₃. |

0.054% |

Al₂O₃ |

0.406% |

Na₂O |

0.010% |

TiO₂ |

0.071% |

K₂O |

0.110% |

CaO |

0.010% |

Typical values. These do not represent a specification.

The use of silica sand in multimedia water filters or in combination with dual bed anthracite

It offers several advantages in water filtration and treatment.

- Increased filtration efficiency: The combination of silica sand and anthracite allows for better separation of suspended particles in the water, as sand has smaller grains and is heavier than anthracite. This ensures that the sand layer is deposited below the anthracite and provides finer filtration.

- Higher solids holding capacity: Multimedia filters with silica, garnet and anthracite sand have a higher solids holding capacity compared to single sand filters, allowing the filter to run longer before requiring backwashing.

- Improved flow distribution: The combination of silica sand and anthracite improves the distribution of water flow through the filter, resulting in more uniform and efficient filtration.

- Reduced backwashing frequency: Due to the higher solids holding capacity and better flow distribution, silica sand and anthracite media filters may require less backwashing than single sand filters, reducing water and energy consumption.

In summary, the combination of silica sand and anthracite in multimedia water filters offers advantages in terms of filtration efficiency, solids holding capacity, flow distribution and less frequent backwashing.