Description

The manual deep bed filter with dual loading.

This deep bed filter is a simple single tank unit with Carbotecnia dual loading and manual control valve. Recommended for domestic or commercial use, and operation less than 23 h.

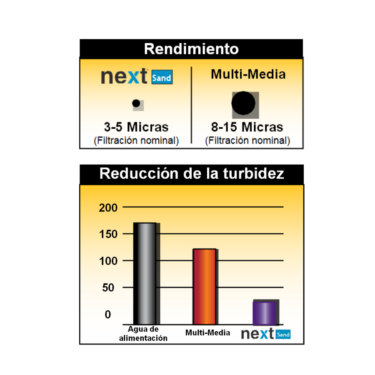

This filter consists of a bed of number one anthracite with an effective size (E.T.) of 0.85 – 0.95 mm; placed on a bed of 16 x 35 U.S. Std. silica sand. Mesh with an E.T. of 0.44 – 0.52mm, 1/8 x 1/16 U.S. Std. silica gravel is used in this filter. Mesh as a support medium.

The granular media used in the Carbotecnia dual bed are evaluated in accordance with the quality parameters specified by AWWA in standard B-100.

Code |

Tank size (in) |

Bed volume (ft3) |

Normal service flow (lpm) |

Normal service flow (gpm) |

Maximum service flow (lpm) |

Maximum service flow (gpm) |

Backwash flow (lpm) |

Backwash flow (gpm) |

Manual Valve |

Input/Output Connections |

Connections Drainage |

|---|---|---|---|---|---|---|---|---|---|---|---|

P_611001 |

8×44 |

0.75 |

9 |

2.5 |

13.2 |

3.5 |

26.5 |

7 |

Purago F1 |

1″ |

1″ |

P_611002 |

9×48 |

1 |

12 |

3.1 |

16.7 |

4.4 |

34.07 |

9 |

Purago F1 |

1″ |

1″ |

P_611003 |

10×54 |

1.5 |

15 |

3.9 |

20.8 |

5.5 |

37.85 |

10 |

Purago F1 |

1″ |

1″ |

P_611004 |

12×52 |

2 |

21 |

5.5 |

29.9 |

7.9 |

56.78 |

15 |

Purago F1 |

1″ |

1″ |

P_611005 |

13×54 |

2.5 |

24 |

6.4 |

34.8 |

9.2 |

71.92 |

19 |

Purago F1 |

1″ |

1″ |

P_611006 |

14×65 |

3 |

28 |

7.5 |

40.5 |

10.7 |

83.27 |

22 |

Purago F2 |

2″ |

2″ |

P_611007 |

16×65 |

4 |

37 |

9.8 |

53 |

14 |

109.77 |

29 |

Purago F2 |

2″ |

2″ |

P_611008 |

18×65 |

5 |

47 |

12.4 |

67 |

17.7 |

140.05 |

37 |

Purago F2 |

2″ |

2″ |

P_611009 |

21×62 |

7 |

64 |

16.9 |

91.2 |

24.1 |

166.54 |

44 |

Purago F2 |

2″ |

2″ |

Components of a deep bed filter:

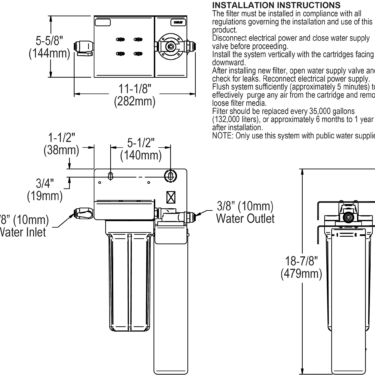

Fiberglass tank: made of a single piece lined with fiberglass for mechanical resistance and an inner polyethylene cover. It is maintenance free. Max. operating pressure 150 psi.

Head or control valve: it is the component in which the inlet, outlet and drain connections are made; it allows us to change between the different service or backwash positions, manually or programmed to do it automatically. Max. operating pressure 125 psi.

Granular filter media: it is a bed consisting of anthracite number one with an E.T. of 0.85 – 0.95 mm and silica sand 16 x 35 U.S. Std. Mesh with T.E. of 0.44 – 0.52mm.

Lower distributor and distribution pipe: The distributor is a micro-grooved element, placed at the bottom of the tank, which allows a correct distribution of the flow in the backwash position and operates as a physical barrier that does not allow the granular medium to escape to the outlet line in the service position. There are simple, stack type distributors or distributors with lateral tubes, spider type; their selection depends on the service and backwash flow, as well as the diameter of the tank. Its material of construction is HDPE or ABS. The central pipe is a PVC Ced pipe. 40 connecting the lower distributor to the control head or valve.

Backing gravel: 1/8 x 1/16 U.S. Std. silica gravel, 1/8 x 1/16 U.S. Std. Mesh as a support medium. Having a micro-grooved distributor eliminates the need to place several beds of gravel of different grain size to avoid loss of material.

Operating conditions:

- Input pH: 3-12

- Bed height (in): 30 – 40

- Clearance height for bed expansion (%, min.): 50

- Hydraulic service load (gpm/ft2): 7-10

- Hydraulic backwash load (gpm/ft2): 20 – 22

- Operating pressure: 30 – 100 psi

- Backwash: by pressure differential > 10 psid or by time every 72 hours max.

- Lifetime of granular media: 3 to 5 years

More information:

How is a deep-bedded bed composed?

What is deep bed filtration?

What is microfiltration?

What are micrometers, microns or microns?

Difference between water filtration and water purification

Introduction to sediment filtration in liquids

Filter media for liquids

Selection of a distributor or nozzle for a deep bed filter

Disc filters

Source:

The 3 essential steps for reverse osmosis pretreatment + 1 optional step