Zeolite is a mineral composed of aluminosilicates, which means that its chemical structure involves aluminum, silicon and oxygen that are organized in the form of AlO4 and SiO4 crystals. This crystalline composition causes the material to have a network of microporous-sized channels and cavities.

The microporous structure of zeolite gives it a large internal specific surface area that allows it to adsorb particles of specific sizes.

Zeolite is also negatively charged due to the presence of aluminum atoms in the silicon matrix that seek balance by positive ions such as sodium, potassium and calcium. This is why zeolites, due to their chemical composition, have the ability to trap positively charged molecules within their crystals by the process of cation exchange.

Some of the other outstanding characteristics of this material, in addition to adsorption and cation exchange, are thermal stability, high water absorption capacity and also being a catalyst for chemical reactions.

Both the physical and chemical characteristics of zeolite make it useful in various industries and applications.

Zeolite, what is it used for in water filtration?

Zeolite is used in water treatment as a filter media that does not need to be combined with any other media and that can retain contaminants larger than 5 microns, becoming even more efficient than deep bed filters in which other materials are used for the retention of sediments and suspended particles present in the water.

Zeolite, due to its resistance, can operate with higher flow rates and last much longer without the need to be replaced compared to common granular media filters. Due to its chemical characteristics, zeolite can remove contaminants through ion exchange by removing contaminant cations from the water.

Reverse osmosis pretreatment

Zeolite serves to remove sediments and suspended particles by means of its porous structure. By passing through zeolite, the water improves its turbidity while preventing these contaminants from clogging the sensitive reverse osmosis membranes.

Gravity pressure filters

Zeolite improves water quality by reducing turbidity and removing contaminants, with a lower pressure drop compared to other filter media, allowing for superior performance and higher filtration efficiency. The low resistance to water flow through the zeolite allows treatment of larger volumes of water with less energy and greater efficiency.

Wastewater polishing

In the final treatment or “polishing” of wastewater, zeolite is used to remove the last traces of suspended solids. Its high particle capture efficiency significantly improves the clarity of treated water, making it suitable for discharge or reuse.

Removal of precipitated metals

Through ion exchange and adsorption, zeolite can capture metal ions, even after they have been treated to precipitate out of solution.

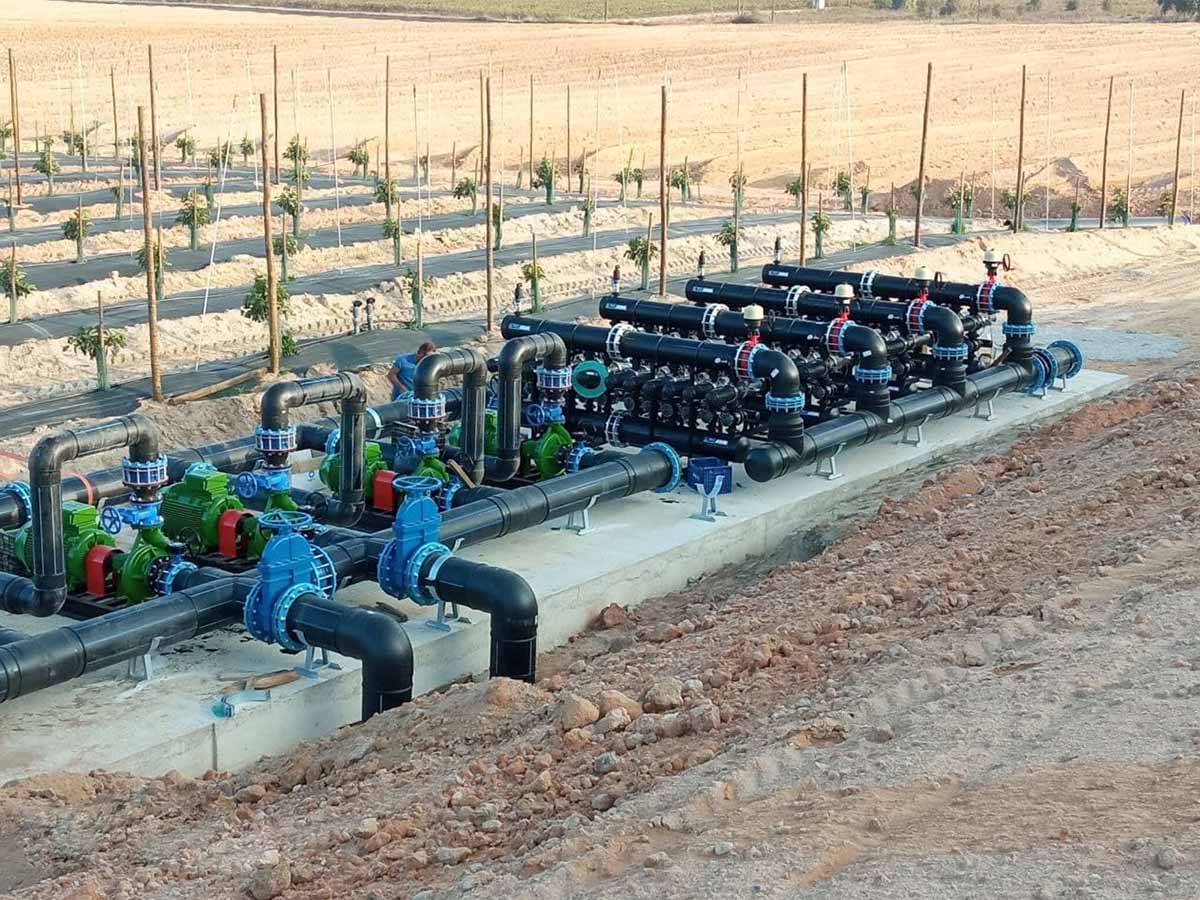

Irrigation

Zeolite can remove contaminants and adjust water quality to make it more suitable for irrigation, including reducing salinity in certain cases.

Cooling towers

Mechanical adsorption and filtration capabilities effectively reduce deposit formation in systems such as cooling towers, improving heat exchange by keeping heat transfer surfaces clean and efficient.