What is filtration and what are the methods of water filtration?

It is a technique used to separate solids in suspension in a fluid, either liquid or gas, using in the process a filter medium which is a porous material called filter or sieve. Filters generally retain larger solids and at the same time allow the fluid to pass through. It is therefore important to know the best filtration method according to the industry in which it will be applied.

Filtration is one of the most widely used methods for the separation of substances. This method is used in different industries, which is why there is a great variety of filtration types depending on the range of precision required.

Filtration with cartridge filters

They are one of the most widely used filtration products because of their usefulness in removing sediments and particles in the water. Solids in the water are usually caused by stormwater runoff and bad pipes that can leave sediment in the water. Water coming out of bad pipes usually discolors and renders it unusable in homes and businesses.

Incidents such as clogging and degradation of water heaters, refrigerators, shower fixtures, valves are very likely to occur. For these cases, water treatment operators use cartridge filters to ensure the use of clean water.

These cartridges use a mechanical filtration process that physically prevents the flow of solids in the water, acting as a kind of water. If these filters are of high quality, they contain porosity of a suitable size for the water to flow without allowing sediments to pass through.

The cartridges can pick up large amounts of dirt if used on large surfaces. Cartridge filters are capable of removing suspended particles by using a gradient density depth construction.

Silica sand filtration

Silica sand serves as a support for drinking water, sewage and wastewater treatment, deep wells, aquariums and decorative. This type of sand is widely used in industrial filters to process wastewater and filter clean water.

A special feature of silica sand is that it has a similar grain size to each other and is a material that does not degrade and resists water impurities such as solvents, acids, organic compounds and pollutants.

This material is used for filtration of water with low to medium contaminant loads that require retention of particles up to 20 microns in size.

Filtration quality may vary depending on parameters such as filter shape, filter bed height, characteristics and granulometry of the filter media. Finally, it should be clarified that the main function of filters is to trap contaminants that float in the liquid and allow water to pass through.

An advantage of the sand filter is that it requires a higher backwashing flow than other deep bed filters, and this means that the filter cleaning is done in a shorter time, thus saving water and time.

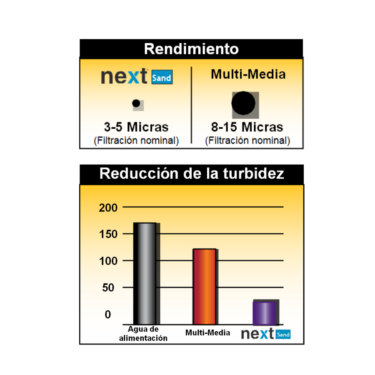

Filtration with multi-branch or multimedia filters

This type of filter has the mission to remove suspended solids in the water with a size of up to 15 micrometers or microns. This means that dust, pollen, small debris, insects, etc., that is larger than the aforementioned size will be retained in filters to be disposed of down the drain at the time of backwashing.

These types of filters are also known as deep bed filters where the upper bed of filtering material has a larger size of fragments, then the water passes to a layer of smaller size to finally pass through a thin layer of fine fragments in the lower one supported by gravel.

Usually the shape of these filters is cylindrical and vertical, they are made of carbon or stainless steel and contain polyethylene inside and fiberglass all over the outside.

Broadly speaking, these filters work as follows: the water enters through the upper part of the filter and flows downwards through the beds, the water is collected in the lower part of the bed thanks to diffusers. Multi-bed filters must be backwashed after a certain period of service in order to expel the retained solids and cause movement in the different filter beds to avoid cementation.

Usually the bed or multi-bed is formed by:

Filtration with disc filters

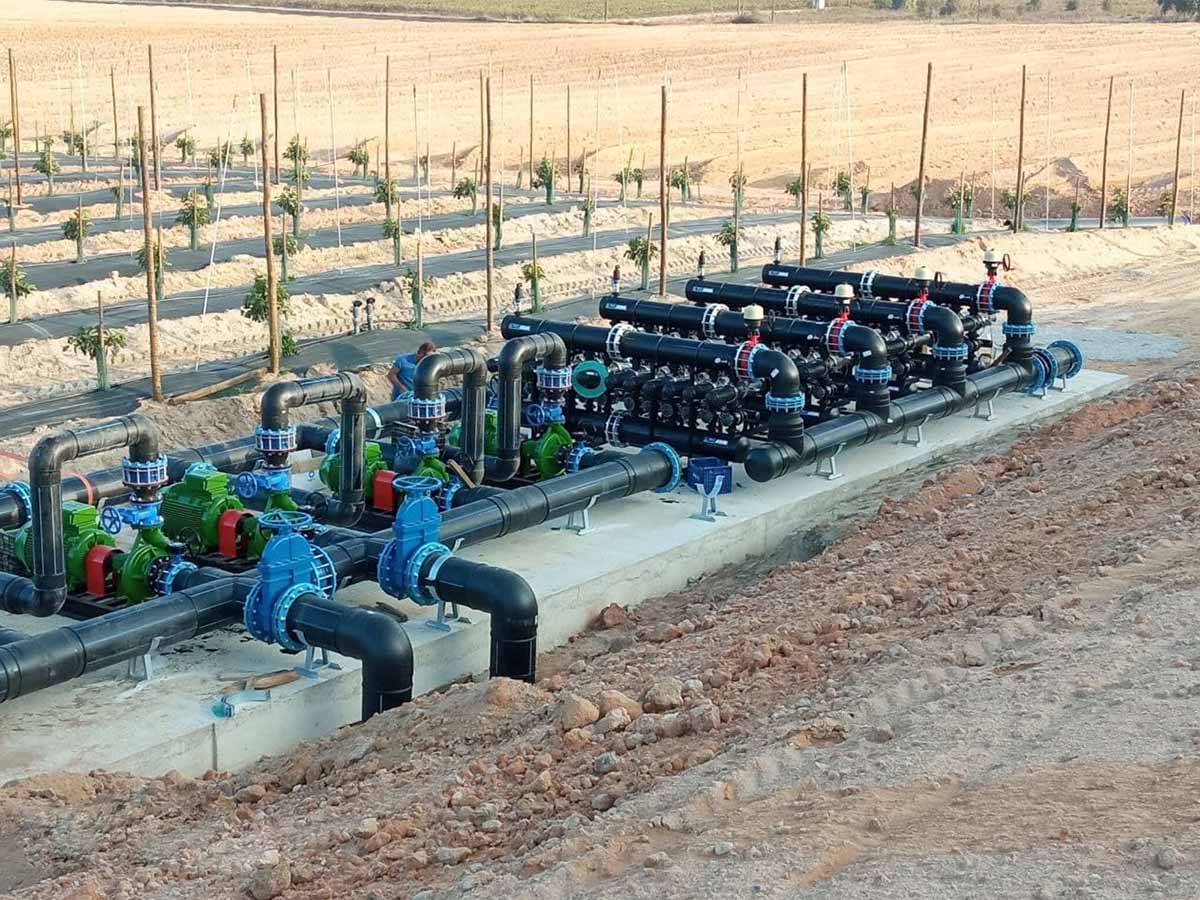

The main function of disc filters is to retain solids in the water. At the beginning they were thought to filter irrigation water and as it was used they found the variety of functions that it has in the filtration of industrial and domestic water.

The discs are ring-shaped and when placed one on top of the other they leave a central hollow and each disc has grooves that are more open on the outside perimeter and narrower on the inside, Their filtration range is from 5 to 400 microns, although they are typically used for large volumes with a filtration of between 100 and 130 microns. Its effectiveness is not only due to its grooves but also to its geometry, angulation, intersections, length and quantity.

As for its operation, the water flows from the outside to the center channel, the solids remain in the channels, the larger ones in the outer part and the smaller ones reach the inner part. This operation minimizes the frequency with which it will be necessary to clean discs, therefore it has a function similar to a depth filter.

The major advantage of disc filters in the space-saving, as a stack of disks can be formed, which can grow in modules vertically or horizontally, but the best thing is the water savings, which approximately in 10 and 30 % savings vs. deep bed, but the disc filter option The water savings can be 80 to 90% compared to the water used in deep bed filters, and the water savings can be as high as 80% to 90%.

Filtration with ultrafiltration membranes

Ultrafiltration is a membrane separation process used in water treatment that makes possible the mechanical separation of suspended or dissolved solids between 0.01 to 0.1 μm (micrometers).

Ultrafiltration membranes are in contact with two liquid phases at different hydrostatic pressure and there will be components of the liquid phase that will go from the high pressure side to the low pressure side.

Small particles that are dissolved in the liquid can pass through the porous membrane, while large dissolved molecules and suspended solids will be retained.

Ultrafiltration is generally used as pretreatment in surface water, seawater, groundwater, graywater treatment, biologically treated effluents and as pretreatment of water for re-treatment with membrane demineralization systems.

Filtration with nanofiltration membranes

This filtration method called nanofiltration is usually used in waters with low solids that are totally dissolved. This system could be consideredbetween reverse osmosis and ultrafiltration because of the levels of separation it allows and the pressures required for its application, the retained solids are between 0.001 to 0.01 μm (micrometers).

This process is generally used for water softening or softening, to remove heavy metals in wastewater, to decontaminate wastewater, to pre-treat water prior to reverse osmosis, to remove nitrates or to remove colors.

It works by means of pressure in membranes that allow the concentration of organic solutes, therefore low molecular weight solutes are retained but salts can pass totally or partially through the membrane.

There are two types of membranes for nanofiltration: spiral wound membranes and tubular membranes, the former are more sensitive to pollution, although their quality is lower than tubular membranes.

Reverse osmosis membrane filtration

In this filtration method, water is passed through a concentrated solution through membranes that are semi-permeable. The pressure applied to the water is higher than the osmotic pressure and thus the salts are retained.

Semi-permeable membranes only allow certain types of ions to pass through, as water passes through the membranes and dissolved ions are retained. It should be clarified that the pressure in the water is equivalent to the salt contained in the water.

Reverse osmosis has 3 streams, the feed, the concentrate:

- The feed stream is the flow of the incoming water.

- There are two types of water streams in the permeate which is purified water and concentrate.

- Concentrate refers to the water that could not pass through the membrane and also contains the rejected salts.

Reverse osmosis filtration is the most widely used purification method in our times, as it is very effective in eliminating almost all ions from the water, and due to the massification of its use, it has become cheaper and has been replicated by many manufacturers.

Conclusion:

There is no one method of filtration better than another, the important thing is to know how to identify which one works best for us depending on the task for which we are going to need it, fortunately today there is a wide variety of options thanks to technology, so we hope this article will help you to identify the best option for you.