Description

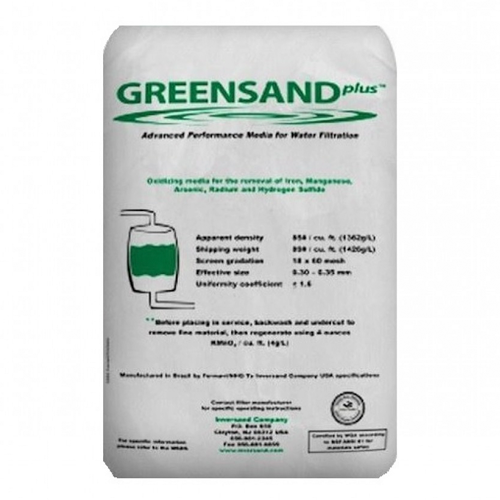

Greensand plus (green sand).

Greensand is a purple-black medium used for removal of iron, manganese and hydrogen sulfide from water. It can also remove radium and arsenic. It is processed with glauconite and zeolite minerals.

Manganese dioxide acts as a catalyst in the oxidation-reduction reaction of iron and manganese leading to their precipitation in the medium. This material must be regenerated in either continuous or intermittent operation and may use chlorine or permanganate for regeneration.

In addition, the greensand is manufactured under the American ANSI/NSF Standard 61 for drinking water treatment components.

Mesh size: 18 X 60

Packing : 0.5 ft3 (20 kg) bags

Color: light brown to reddish brown

Density: 100 lbs / ft3

Mesh size: 18×35

Effective size: 0.45-0.55 mm

Coefficient of uniformity: 1.6 or less

Acid Solubility: 0.3 – 1.6%.

Greensand plus uses silica sand coated with manganese dioxide which acts as a catalyst in the oxidation-reduction reaction of iron and manganese. The difference between Greensand Plus and manganese greensand is in the substrate that forms the core of the filter media and the method by which the manganese dioxide coating binds to that substrate. Greensand Plus uses silica sand that is strongly fused to it, while manganese Greensand has an ionically bonded glauconite core, being weaker.

The silica sand base of the Greensand Plus allows it to better withstand operating conditions in waters with low silica, TDS and hardness. Therefore, if you are currently using manganese greensand and are feeding sodium aluminate, you will probably be able to eliminate the aluminate feed by switching to Greensand Plus. Also, Greensand Plus can withstand higher melt temperatures and elevated pressure differentials. High pressure differentials may allow runs for longer periods.

Greensand Plus is an exact replacement for greensand manganese greensand. The green sand filters (greensand plus) are calculated to the needs of each water by our team.

Advantages:

Iron removal over the entire pH range

Effective removal of hydrogen sulfide in addition to iron and / or manganese

Chlorine can be used as a regenerant.

Low wear loss for long bed life.

Operating conditions:

pH of water – 6.2 to 8.5

Bed depth – 30 inches

Bedding space – 35 – 50%.

Service flow rate – 2 – 5 gpm / sq. m3 / sq. ft. feet (5-12 m / h)

Backwash flow – 12 gpm / sq. ft. feet at 55º F (30 m / hr at 13º C)

Maximum temperature – No limits

Practical maximum limit of iron (Fe++) or manganese (Mn++) in raw water – 15 ppm.

Maximum practical limit for hydrogen sulfide (H2S) – 5 ppm.

More products for iron and manganese removal here: https://www.filtrashop.com/?s=arena+green&post_type=product