Description

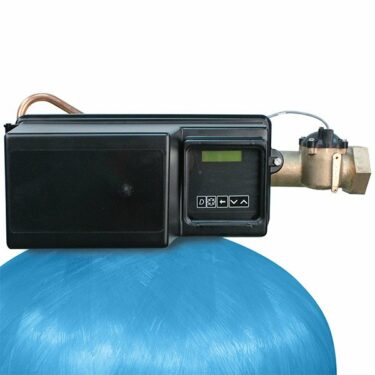

Control valve 565 Canature control valve for filter or softener

The 565 Canature control valve for filters and softeners is NSF/ANSI 44 certified so its quality and reliability is guaranteed for water treatment systems.

Among its most outstanding features is its diagnostic capability, which includes tracking the current flow rate and total gallons treated, through a 2-line, 16-character backlit LCD display, facilitating monitoring and maintenance.

The valve offers a seven-year warranty in the event of a manufacturing defect.

Water flow at 50 psi at the inlet

Continuous flow (15 psi pressure drop)

Maximum flow (25 psi pressure drop)

Maximum Backwash (25 psi pressure drop)

Volumetric flow coefficient

Standard applications

Softener

Filter

Electrical specifications

Input voltage

Output voltage

Safety certificate

Operating parameters

Maximum operating pressure

Working temperature limit

1.

NSF 44 Certification

It incorporates piston, seal and spacer in a reliable NSF/ANSI 44 certified design.

2.

Easy to use

2-line, 16-character backlit LCD display for ease of use.

3.

Downstream regeneration

The flow runs from top to bottom, so the entire medium is regenerated.

4.

Automatic rotary diagnostics

Obtain key information such as current and maximum flow, gallons treated, total regenerations, date of last regeneration, etc.

5.

Variety of measurement modes

Vacation mode, calendar, immediate meter, override meter and delay meter.

6.

Easy installation and maintenance

Time saving thanks to its quick connections on the power cable, drain line and brine line.

7.

Self-charging capacitor

8.

Meter configuration

It includes immediate meter, counting meter and meter with suspension, as well as calendar clock modes.

9.

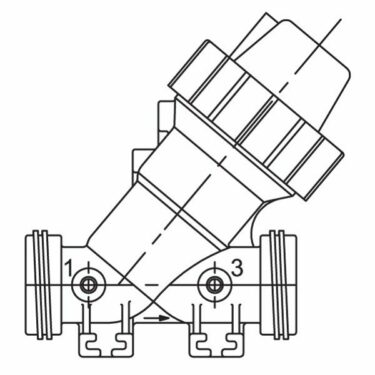

Integrated design

Integrated turbine flow meter, bypass and installation accessories.

10.

Adjustable regeneration

Regeneration cycles are easy to program and can be set by flow or time.

11.

Electronic sensors

Accurate electronic sensors to locate piston positions.

12.

7-year warranty

Device covered for seven years against manufacturing failures.

Comparative table of control valves

Features |

65CC |

765 |

565 |

785 |

89 |

95 |

105 |

Valve material |

Noryl (PPO) |

Noryl (PPO) |

Noryl (PPO) |

Noryl (PPO) |

Noryl (PPO) |

Noryl (PPO) |

Noryl (PPO) |

Input / Output |

3/4″, 1″ |

3/4″, 1″ |

3/4″, 1″ |

3/4″, 1″ |

1″ |

1″, 1-1/4″, 1 1/2″ |

2″ |

Service flow (gpm) |

20 GPM |

20 GPM |

20 GPM |

20 GPM |

27 GPM |

39 GPM |

70 GPM |

Maximum flow (gpm) |

26 GPM |

26 GPM |

26 GPM |

26 GPM |

35 GPM |

50 GPM |

90 GPM |

Backwash flow (gpm) |

7 GPM |

7 GPM |

7 GPM |

17 GPM |

27 GPM |

32 GPM |

70 GPM |

Upflow / Downflow |

NA / X |

NA / X |

NA / X |

X / X |

X / X |

NA / X |

NA / X |

Adjustable cycle time |

NA |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Duplex |

NA |

NA |

NA |

NA |

NA |

Yes |

Yes |

Multiplex |

NA |

NA |

NA |

NA |

NA |

Yes |

Yes |

Drainage size |

1/2″ |

1/2″ |

1/2″ |

1/2″ |

3/4″ |

3/4″, 1″ |

1.5″ o 2″ |

Brine size |

3/8″ |

3/8″ |

3/8″ |

3/8″ |

3/8″ |

3/8″, 1/2″ |

1/2″ |

Pilot distributor |

1.05″ |

1.05″ |

1.05″ |

1.05″ |

1.05″ |

1.5″ |

1.5″ |

Filter tank size |

10″ |

10″ |

10″ |

16″ |

18″ |

21″ |

30″ |

Softener tank size |

16″ |

16″ |

16″ |

16″ |

18″ |

24″ |

36″ |

More information about filtration:

How is a deep-bedded bed composed? Dual or Multimedia