What is the difference between a nominal filter and an absolute filter?

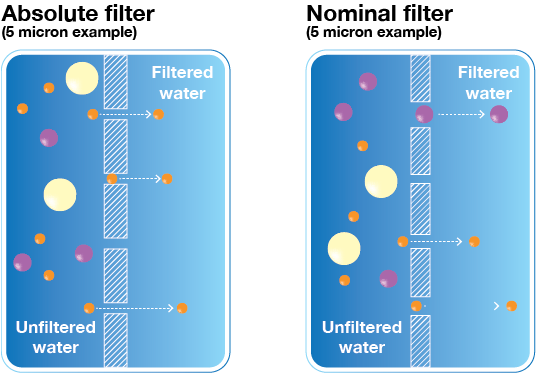

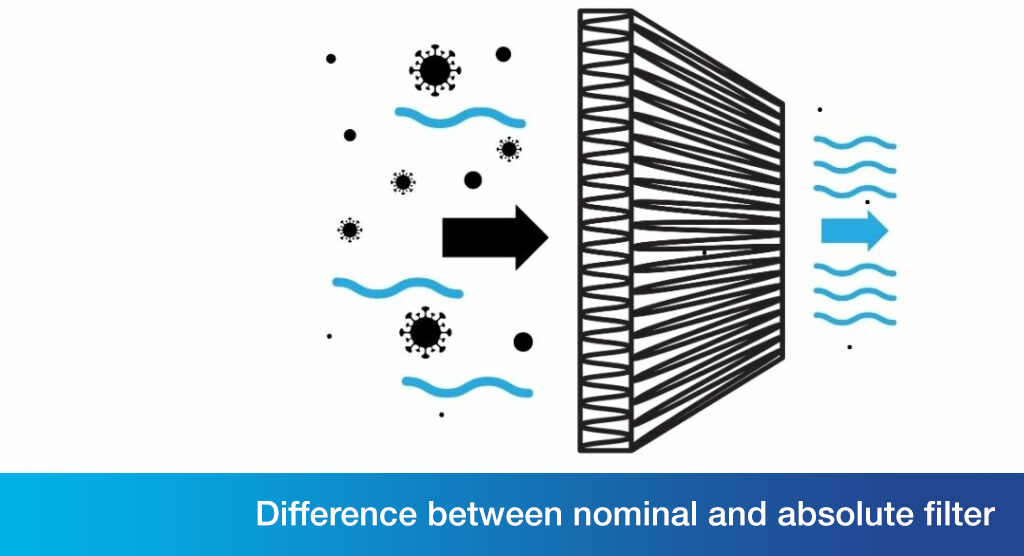

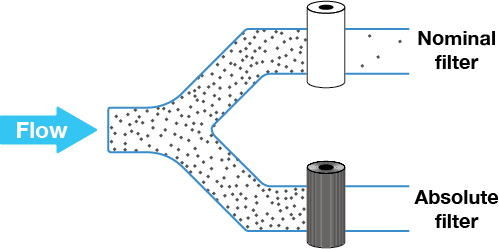

Nominal filters and absolute filters are two types of filters that have different filtration capacities. Nominal filters have a set pore size range and a nominal particle retention efficiency, which means that they retain a significant amount of particles of a specific size, but not all particles. Absolute filters, on the other hand, have a retention efficiency of 99.9% for all particles of the specified size.

The specific difference between nominal and absolute microns in a filter refers to the filter’s ability to retain particles of different sizes. The nominal micron rating is used to indicate the ability of a filter to retain a minimum percentage of particles of a specific size. For example, a nominal 1 micron filter may retain at least 95% of particles 1 micron or larger, but may also allow some smaller particles to pass through.

Alternatively, the absolute micron rating indicates that no particles larger than the stated range will be able to pass through the filter, retaining 99.9% of particles equal to or larger than the specified size. For example, a 1 micron absolute filter will retain all particles 1 micron or larger, without allowing any particles larger than 1 micron to pass through.

It is important to note that the actual holding capacity of a filter may vary depending on the manufacturer and the specific filtration conditions. Therefore, it is advisable to consult the specifications provided by the filter manufacturer to understand the retention efficiency in both nominal and absolute microns.

Example of an Absolute vs a Nominal filter

What are nominal filters?

Nominal filters in the field of filtration refer to those filters capable of retaining a minimum amount of solid particles of a specific size, usually expressed in micrometres or microns (µm), and with a nominal retention efficiency. These filters are designated with a percentage and a particle size, such as “95% of 10 microns”. This means that the filter is capable of retaining at least 95% of particles 10 microns or larger, but may allow some larger particles to pass through. Not all cartridge filter manufacturers have the same criteria for determining the percentage of particles they can let through outside the specified micron size; some may have 80%, 90% or 95%.

A common example of nominal cartridge filtration is the use of sediment filters in drinking water applications. These nominal cartridges can be used to retain sediment and larger particles, such as sand, clay or rust, providing visually cleaner water.

Another example of nominal filtration is the use of filters in the chemical and pharmaceutical industry, where a minimum retention of solid particles is required to ensure the quality of the final product. These filters can retain particles of a specific size to prevent them from entering the production process.

It is important to note that nominal filters have a degree of retention that may vary and do not provide accurate and absolute filtration. Therefore, if more accurate filtration is required, it is recommended to use absolute filters that have a certified retention efficiency.

What are absolute filters?

Absolute or absolute micron filters are high efficiency filters with extremely high particle holding capacity, generally designed to retain a minimum amount of particles of a specific size with a certified retention efficiency. That is, if the filter cartridge states that it is 5 microns, the cartridge is capable of retaining 99.9% of particles larger than 5 microns. The EN-1822 standard defines three classes of absolute filters according to their filtration efficiency:

- EPA (Efficiency Particulate Air)

- HEPA (High Efficiency Particulate Air)

- ULPA (Ultra Low Penetration Air).

Common examples of absolute cartridge filtration include HEPA filters used in air conditioning applications, ventilation and air cleaning systems, and ULPA filters used in clean room applications and semiconductor production equipment.

In addition, absolute filters are also used in pharmaceutical and laboratory applications, where extremely accurate water or liquid filtration is required to ensure the quality of the final product. Other examples include oil and gas filtration systems, operating rooms, laboratories and production areas where hazardous chemicals are handled.

It is important to note that, unlike nominal filters, absolute filters have a certified retention efficiency, which means that they are able to retain a minimum amount of particles of a specific size with a known retention efficiency.

In absolute micron cartridge filtration What is the BETA test method for measuring filter efficiency?

In absolute micron cartridge filtration What is the BETA test method for measuring filter efficiency?

Beta absolute and nominal cartridge filtration

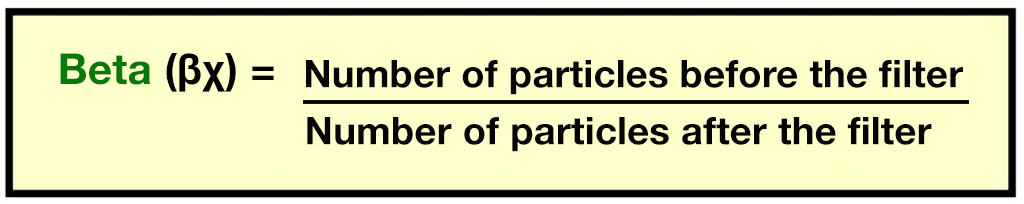

The BETA index allows easier and more accurate comparison of test results. This test uses a specific contaminant, of known size, which is added in measured quantities to the fluid being pumped through the filter. At set time intervals, simultaneous samples of fluid are taken both downstream and upstream of the filter, measuring the particulates in each sample. Based on the results a Beta index is determined which is an indicator of how well the filter controls a specific particle size. Filters with a higher BETA index retain more particles and are therefore more effective.

In absolute cartridge filtration, the Beta 1000 method is a rating that indicates the particle retention efficiency of a filter. The international standard ISO 16889 lists several common beta ratios that are used to indicate the efficiency of a filter, among them is Beta 1000.

Beta rating refers to the ability of a filter to retain particles of a given size. Beta 1000 means that the filter has a retention efficiency of 99.9% for particles of the specified size (absolute micron). This implies that the filter is highly efficient and retains the vast majority of particles of that size.

It is important to note that the Beta 1000 method is only one of several beta ratings used to assess filter efficiency. There are also higher beta ratings, such as Beta 5000, which indicate higher particle retention efficiency.

Beta (βχ) |

Efficiency (%) |

|---|---|

2 |

50 |

10 |

90 |

100 |

99 |

1000 |

99.9 |

5000 |

99.98 |

Other methods used to measure the effectiveness of an absolute or nominal cartridge filter.

There are several methods for measuring the efficiency of absolute filters used in cartridge filtration of liquids. One of the most common methods is the filter integrity test, which evaluates the filter’s ability to retain particles on its surface or in its matrix due to the formation of a protective layer during use.

Filter integrity test method:

This method is used to verify the integrity of the filter and to ensure that there is no leakage or damage to the filter media or cartridge. It is performed by using a specific test substance and detecting if there is any leakage through the filter.

Filter integrity testing can be carried out using different methods, depending on the type of filter being used. For example, for cartridge filters, the bubble test, differential pressure test, pressure drop test or fluorescence test can be used.

In the bubble test, the filter cartridge is immersed in a liquid and compressed air pressure is applied to the inside of the filter. If the filter is defective or has a pore size that is too large, bubbles will appear on the surface of the cartridge. In the differential pressure test, the pressure difference across the filter before and after use is measured to detect any decrease in filtration capacity. In the pressure drop test, the pressure on both sides of the filter is measured to verify adequate liquid flow. The fluorescence test is used to detect the presence of particles that are not directly visible or to check the quality of the filter cleaning between uses.

Particle retention efficiency test method:

This method assesses the filter’s ability to retain particles of a specific size. Test particles of known size are used and the amount of particles passing through the filter is measured.

Flow test method:

A flow test can also be performed to assess the efficiency of the filter. The flow rate of liquid passing through the filter is measured and compared to the expected flow rate.

It is important to select the appropriate test technique according to the specific cartridge filter applications used for liquid filtration.

In conclusion, the main difference between nominal filters and absolute filters is the level of filtration efficiency, and the type of products that may require it will depend on the specific application.

Sources:

https://www.lenntech.es/filtros-y-filtracion/filtros-absoluto-nominal.htm

https://www.dudadiesel.com/choose-item.php?id=SedimentFilter

Filtros de cartucho absolutos y nominales disponibles

-

BEVPOR PS – Final Microbial Stabilization Filter Cartridge

Add to quote -

Hydronix Pleated Cartridge Filter

Add to quote -

Polyspun 2.5 “x30” Hydronix Cartridges

Add to quote -

Polydepth Pentek Cartridge

Add to quote -

Inline Sediment Filter Cartridge ISF-10

Add to quote -

2.5 “x20” Hydronix Pleated Cartridges

Add to quote -

Polyflow-G Pleated Depth Filter Cartridge

Add to quote -

3M Betapure AU Cartridge

Add to quote -

Sterilizing Grade Pharmaceutical Liquid Filters – PROPOR SG

Add to quote -

Hydronix SBC Series Hot Melt Depth Cartridges

Add to quote -

Abso-Mate™ Pleated Melt Blown Filter Cartridges

Add to quote -

3M Micro-Klean RT Cartridge

Add to quote -

MegaBond Nominal Melt Blown Filter Cartridges

Add to quote -

3M 740B series High Performance Cartridge

Add to quote -

Hydronix Yarn Cartridges

Add to quote -

3M Betapure NT-T Cartridge

Add to quote

In absolute micron cartridge filtration What is the BETA test method for measuring filter efficiency?

In absolute micron cartridge filtration What is the BETA test method for measuring filter efficiency?