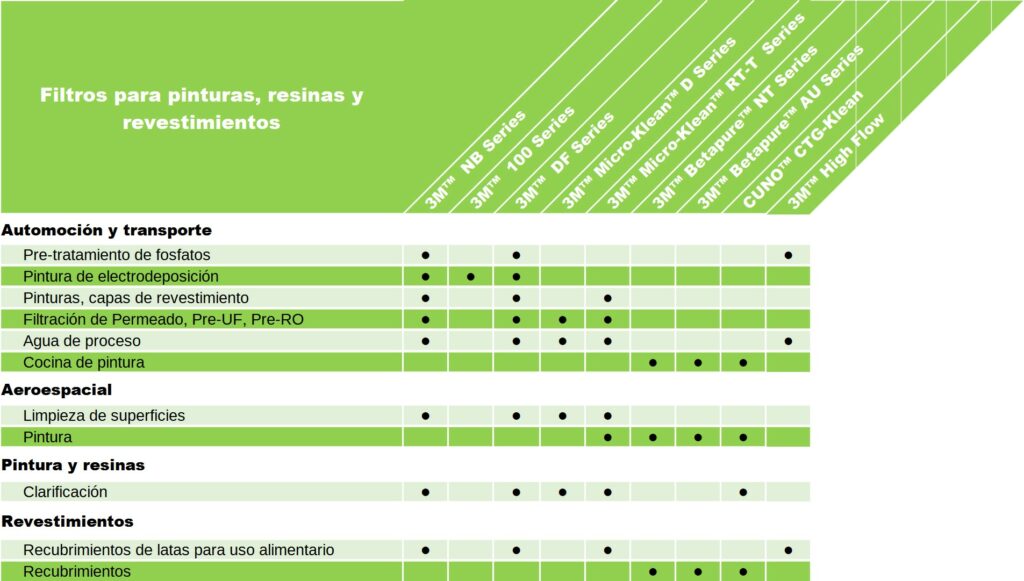

Description

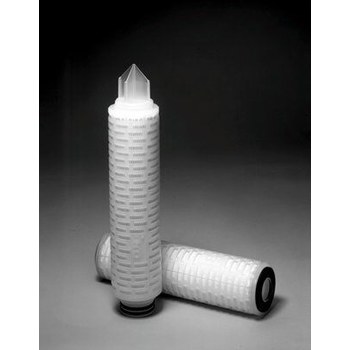

3M Betapure AU rigid filter cartridge

3M Betapure AU series rigid filter cartridges are designed to provide optimum filtration quality. Its controlled pore size allows two different micron sizes to be separated in the same cartridge for effective filtration. These cartridge filters offer consistent contaminant reduction, maintain good flow through and superior service life. 3M Betapure AU series cartridges are available in 18 different ratings with absolute values ranging from 2 to 190 microns absolute, allowing you to select the exact filtration characteristics.

The same cartridge offers two micron ratings; absolute and nominal.

| Microns (µm) | ||

| Code | Absolute | Nominal |

| Z13 – 020 | 2 | 0.2 |

| Z13 – 030 | 3 | 0.3 |

| Z13 – 050 | 5 | 0.5 |

| Z11 – 060 | 6 | 0.6 |

| Z11 – 070 | 7 | 0.7 |

| Z11 – 080 | 8 | 0.8 |

| Z11 – 100 | 10 | 0.9 |

| Z11 – 120 | 12 | 1 |

| Z11 – 150 | 15 | 3 |

| B11 | 20 | 5 |

| C11 | 30 | 10 |

| E11 | 40 | 20 |

| G11 | 70 | 30 |

| L11 | 90 | 50 |

| Q11 | 100 | 75 |

| V11 | 140 | 100 |

| W11 | 160 | 150 |

| X11 | 190 | 175 |

3M Betapure AU cartridge applications:

Coatings: High quality paints, film coatings, resins and inks.

General Industry: Desalination, coating, process water

Electronics: RO reverse osmosis pretreatment, ceramic slurries, chemical-mechanical polishing

Chemical/Petrochemical: Process water, reverse osmosis pretreatment RO

The rigid filter media of the 3M Betapure AU series cartridges

Reduces cartridge bypass and discharge, ensuring consistent filtration from start to finish. Its depth filtration design reduces deformable contaminants for consistent flow. On the other hand, a rigid depth structure reduces collapse and product quality rejects. This filtration cartridge also provides a long service life inside the cartridge holder and is available in several standard sizes.

The 3M Betapure AU series has developed a clean and rigid filter production technology with consistent and reproducible filtration characteristics. The filter structure is constructed using long bicomponent fibers, each fiber having an inner core and an outer sheath. AU series filters are manufactured using two bicomponent fiber structures, propylene/polyethylene or polyester/copolymer, offering broad compatibility with industrial processes. The rigidity of the 3M™ Betapure™ AU filter structure resists deformation, contaminant discharge or filter bypass, providing efficient removal of unwanted particles. Filter manufacturing ensures batch-to-batch and filter-to-filter product quality consistency and optimum filtrate quality throughout the product life cycle.

These filtration cartridges are available for use in a wide range of applications, including chemical, petrochemical, process water, electronics and other industries, making them ideal for continuous and batch processes. Produced with 3M Betapure technology, these cartridges offer consistent, reproducible and efficient filter quality in their production process.

Solids reduction rates

3M uses a Multi-Parameter Characterization (MPC) which, unlike single point evaluations, determines a reduction rate over a range of particles, which, unlike point evaluations, determines a particle reduction rate (multi-value) and filter life (multi-point). Parameters measured include particle counts, turbidimetric efficiencies and removal efficiencies.