Description

3M Micro-Klean RT Series Water Filter Sediment Cartridges

The 3M Micro-Klean RT series are particle or sediment holding cartridges, nominal, deep, rigid construction, non-deformable at high pressure differentials, constructed of thermofused polypropylene fibers with a high efficiency that prevents detachment. They have the longest service life on the market and cause the lowest pressure drop.

3M Micro-Klean RT Cartridge Basic Features

- Nominal and depth filters.

- Material of construction: 100% polypropylene fibers.

- Filtration grades: 1, 5, 10, 10, 25, 50 and 75 µm.

- Construction method: hot-melt (no resins or other binding agents are used).

- Unlike other hot melt cartridges, Micro-KleanTM RT series filter cartridges are rigid. Therefore, they do not require a rigid core to withstand high pressure differentials.

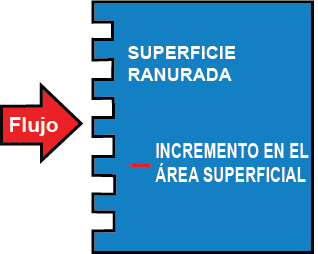

- Slotted outer surface, which more than doubles the area.

- Outside diameter (nominal): 2.6″.

- Inside diameter (nominal): 1.1″.

- Lengths: 9 ¾”, 10″, 19 ½”, 20″, 29 ¼”, 30″, 39″ and 40″.

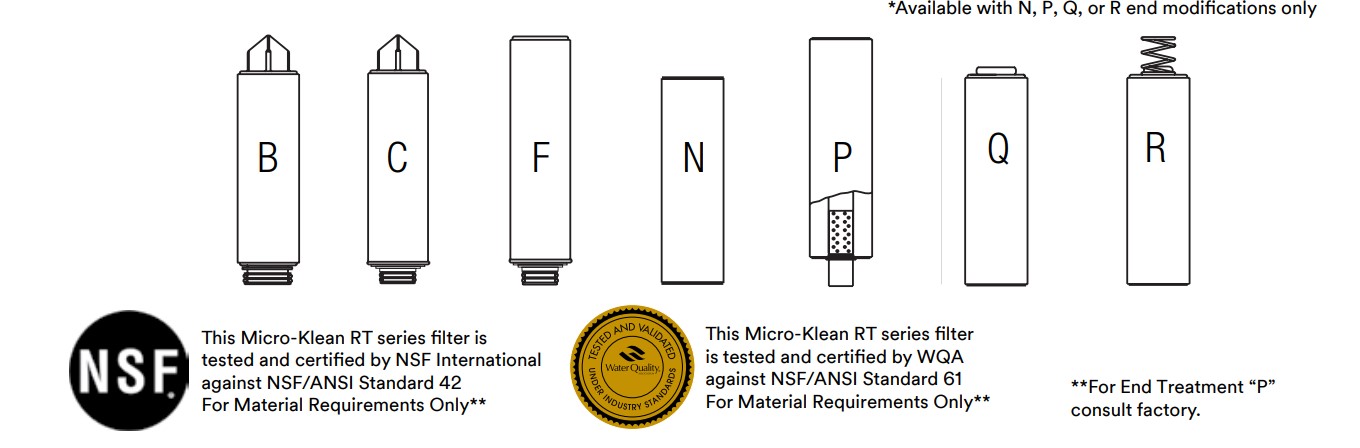

- Terminations: open on both sides(DOE, Double Open End) and open on one side only(SOE, Single Open End).

- The closed end of SOE cartridges can be flat or spearhead.

- The open end of SOE cartridges can be without O-ring, with O-ring 222 or with O-ring 226.

- Maximum operating temperature: 176°F (80°C).

- Recommended pressure differential at which to change the cartridge: 35 psid @ 68°F (2.4 bar @ 20°C) (at this pressure differential, the cartridge maintains its high retention efficiency).

Main competitive advantages of the 3M Micro-Klean RT water filter cartridge water filter

The Micro-KleanTM RT series filter cartridges are the most competitive on the market in terms of

- Efficiency in solids retention at high flow rates (Flux): 65% to 85% of particles greater than the nominal filtration grade of the cartridge are retained).

- Consistency of such efficiency over the life of the cartridge.

- Efficiency in the thermofusion of the fibers that compose them, which prevents them from detaching and being dragged by the filtered liquid.

- Lifetime that is more than twice that of its closest competitor and more than 30 times that of an economical cartridge.

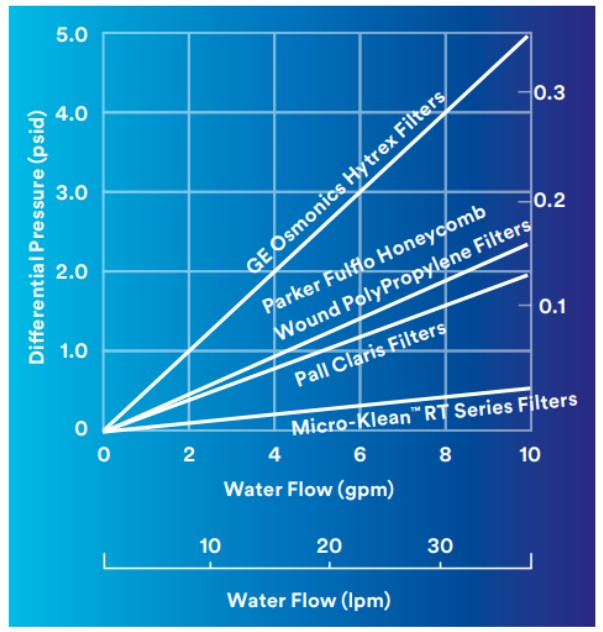

- Lowest initial pressure differential in the market (See Graph 4).

Graph 4.- Flow vs. pressure differential.

* Note to Table 1: this graph corresponds to nominal 5 µm cartridges.

* Note to Table 1: this graph corresponds to nominal 5 µm cartridges.

It is based on the specifications of the literature published by each manufacturer.

Manufacturing technology of Micro-Klean™ RT series filter cartridges explaining their advantages

competitive

- The main reason for the low initial pressure differential and high service life of these cartridges lies in their enormous porosity.

- The efficiency of particle retention at high flow rates is due to state-of-the-art porosity control, tortuosity that maximizes internal solids holding capacity and the hydraulic design of the fluid.

- The manufacturing technology ensures that the outer grooves do not tear or melt the filter structure. On the other hand, they do not represent a risk since they are located upstream. By increasing the surface area, the amount of particles that the cartridge can retain on the outside of the cartridge before clogging increases, which also increases the life of the cartridge.

- The stiffness of these cartridges substantially increases the differential pressure they withstand.

- The stiffness prevents them from deforming as the differential pressure increases, which prevents the pores from collapsing or the filter from leaking particles it had retained. Most competitive cartridges should be changed before reaching 10 psid.

- Since it does not require a rigid core of a different material than the filter media, disposal by incineration or shredding is facilitated.

- Polypropylene (which is the material of construction of these cartridges) is one of the least reactive, most stable polymers with the widest range of chemical compatibility to strong acids and bases, oxidizing agents, mineral oils, alcohols, ketones and other organic liquids. See Table 4.

Table 4.- Fluid Compatibility

Chemical |

Temperature |

Chemical |

Temperature |

Chemical |

Temperature |

Acetic Acid 20%. |

160°F (71°C) |

Hydrogen Peroxide |

100 °F (38 °C) |

Sodium Carbonate |

160°F (71°C) |

Alkanolamines |

140°F (60°C) |

Methyl Ethyl Ketone |

70 °F (21 °C) |

Sodium Hydroxide 70% Sodium Hydroxide |

160°F (71°C) |

Ammonium Hydroxide 10% Ammonium Hydroxide 10% Ammonium Hydroxide |

160°F (71°C) |

Mineral Oil |

70 °F (21 °C) |

Sulfuric Acid 20% Sulfuric Acid |

160°F (71°C) |

Beach 5.5% Beach 5.5% Beach 5.5% Beach 5.5% Beach 5.5% Beach 5.5% |

120 °F (49 °C) |

Nitric Acid 20%. |

120 °F (49 °C) |

Sulfuric Acid (70%) |

160°F (71°C) |

Ethylene Glycol |

160°F (71°C) |

Potassium Hydroxide |

140°F (60°C) |

Urea |

160°F (71°C) |

Practical significance of the initial pressure differential being the lowest in the market

The design and construction of the Micro-Klean™ RT series cartridges results in the lowest initial pressure drop on the market. As shown in Graph 4 at the beginning of this data sheet, for a given differential pressure, the Micro-Klean™ RT series cartridges operate at flow rates up to ten times that of the competitor’s cartridges mentioned above. This means that, for a given flow rate, the investment required in Micro-Klean™ RT series cartridges and the housings in which they are installed is substantially lower.

Sizing of a filtration system with Micro-KleanTM RT series cartridges

Table 2.-Specific Pressure Drop (SPD) caused by Micro-KleanTM RT series filter cartridges

Nominal filtration degree (µm) |

SPD per 10″ cartridge (psid/gpm-Cp) |

SPD per 10″ cartridge (mbar/lpm-Cp) |

1 |

0.073 |

1.330 |

5 |

0.042 |

0.765 |

10 |

0.025 |

0.455 |

25 |

0.015 |

0.273 |

50 |

0.010 |

0.182 |

75 |

0.006 |

0.109 |

gpm = flow, gallons/min

lpm = flow, liters/min

Cp = viscosity, Centipoises

Table 2 shows theSpecific Pressure Drop (SPD) corresponding to the different filtration grades of the Micro-Klean™ RT series filter cartridges.

To calculate the pressure drop caused in a Newtonian fluid by the total number of 10″ equivalent clean cartridges installed in parallel, the SPD value in Table 2 (which corresponds to the required filtration degree) is read and used in the following equation:

ΔP = Pressure drop caused by the total number of clean cartridges installed in parallel, psid [mbar].

F = Total system flow, gpm [lpm].

υ = Viscosity of the liquid, Cp (centipoises).

SPD = Specific Pressure Drop (from Table 2)

N = Number of 10″ equivalent cartridges installed in parallel.

One of the three variables in the equation (ΔP, F or N) can be calculated, if the other two are set.

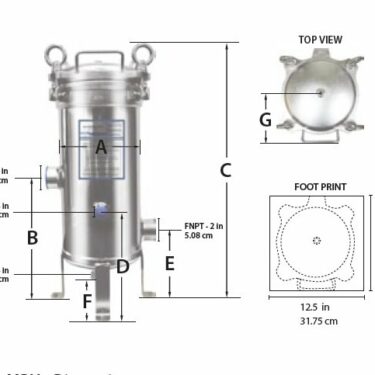

It is important to select a housing in which at least the required number of 10″ equivalent cartridges can be installed, and to verify that the total system flow rate does not exceed the maximum design flow rate.

Applications

Industries |

Electroplating, desalination plants, pulp and paper, additives, cooling water, parts washing, peroxides, mechanical seals. |

Coatings |

Manufacturers of resins (water-soluble and organic soluble), paints, pigments. |

Food and beverages |

Process water to produce beverages, bottled water, beverage dispensers, carbonated beverages, juices, beer, wines, distillates, edible oils, bottle washing. |

Oils and fuels |

Amines and glycol, flood prefiltration, cooling water. |

Chemicals Industries |

Polyethylene, polypropylene, PVC, vinyl monomer, herbicides, pesticides. |

Electronics industry |

Printed microcircuits, electronic capacitors, video screens, reverse osmosis protection, CD/DVD. |

Pharmaceutical Industry |

Reverse osmosis protection, bulk pharmaceutical chemicals, particle control in injectable liquids, rinse water, active pharmaceutical ingredients. |

Micro-KleanTM RT series filter cartridges specifications

| Construction | |

| Filter media and terminal connector | Polypropylene |

| Optional seals and O-rings | Silicone, fluorocarbon, EPR, nitrile, and polyethylene |

| Operating conditions | |

| Maximum operating temperature | 176°F (80°C) |

| Maximum pressure differential | 15 psid @ 176°F (1.0 bar @ 80°C)

25 psid @ 140°F (1.7 bar @ 60°C) 60 psid @ 68°F (4.1 bar @ 20°C) |

| Pressure differential at which change is recommended | 35 psid @ 68°F (2.4 bar @ 20°C) |

| Cartridge dimensions | |

| Inside diameter (nominal) | 1.1″ (28 mm) |

| Outside diameter (nominal) | 2.6″ (66mm) |

| Length | 9 ¾”, 10″, 19 ½”, 20″, 29 ¼”, 30″, 39″ y 40″

(238, 254, 495, 508, 508, 743, 762, 991 and 1016 mm) |

| Quality standards and certificates | |

| Micro-Klean™ RT series filter cartridges are approved for water purification. Materials of construction meet USFDA 21 CFR requirements for food and beverage contact. They are tested and certified by NSF International to NSF/ANSI 42 standard for materials, and are tested and certified by WQA to ANSI/NSF 61 standard.

3M is ISO 9001 certified to ensure quality and provide products that perform consistently. |

|

Micro-KleanTM RT Series Filter Cartridge Ordering Guide

| Cartridge type | Length | Grade | Material | Surface | Packaging | Ring support | Modification of terminations | Packing/0-ring |

|

RT – MicroKlean™ RT Series

|

09 – 9 ¾”*

10 – 10″ 19 – 19 ½”* 20 – 20″ 29 – 29 ¼”* 30 – 30″ 39 – 39″ 40 – 40″ |

Y – 1 µm

B – 5 µm C – 10 µm F – 25 µm L – 50 µm Q – 75 µm |

16 – Polypropylene

|

G – Slotted

|

2 – width

|

0 – none

|

B-226 O-Ring and spear point

C-222 O-Ring and spear point F-222 O-Ring and spear tip N-None P-Polypropylene core stretcher Q-Springless cover R-Spring-loaded lid |

A-Silicon

B-Fluorocarbon C-EPR D-Nitrile N-None*. |

Some information seekers write the name of these cartridge filters as: Micro Klean RT, Micro Clean RT, Micro-Clean RT, Micro Klean-RT, Micro Clean-RT, Micro Clean-RT, Microklean RT, Microclean RT, Microklean-RT, Microclean-RT.

REFERENCES

- 3M Purification Inc., Technical Data Sheet for

Micro-Klean RT Series, All-Polypropylene Rigid Thermal Bonded Filters.

, Meriden, 2018.

DEVELOPMENT AND REVISIONS

Prepared: GGC 27 Feb 2023

Reviewed: