Description

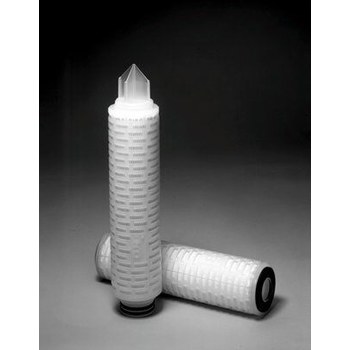

3M Betapure NT-T Absolute filter cartridge

The Betapure NT-T cartridge filter is an advanced cartridge filtration technology from 3M Purification Inc. These depth filter cartridges are made entirely of polypropylene and use an innovative design that combines flow-enhancing filter media and a unique flow pattern. The result is an absolute-rated filter with a much longer operating life, providing more cost-effective filtration than conventional fused filter technologies.

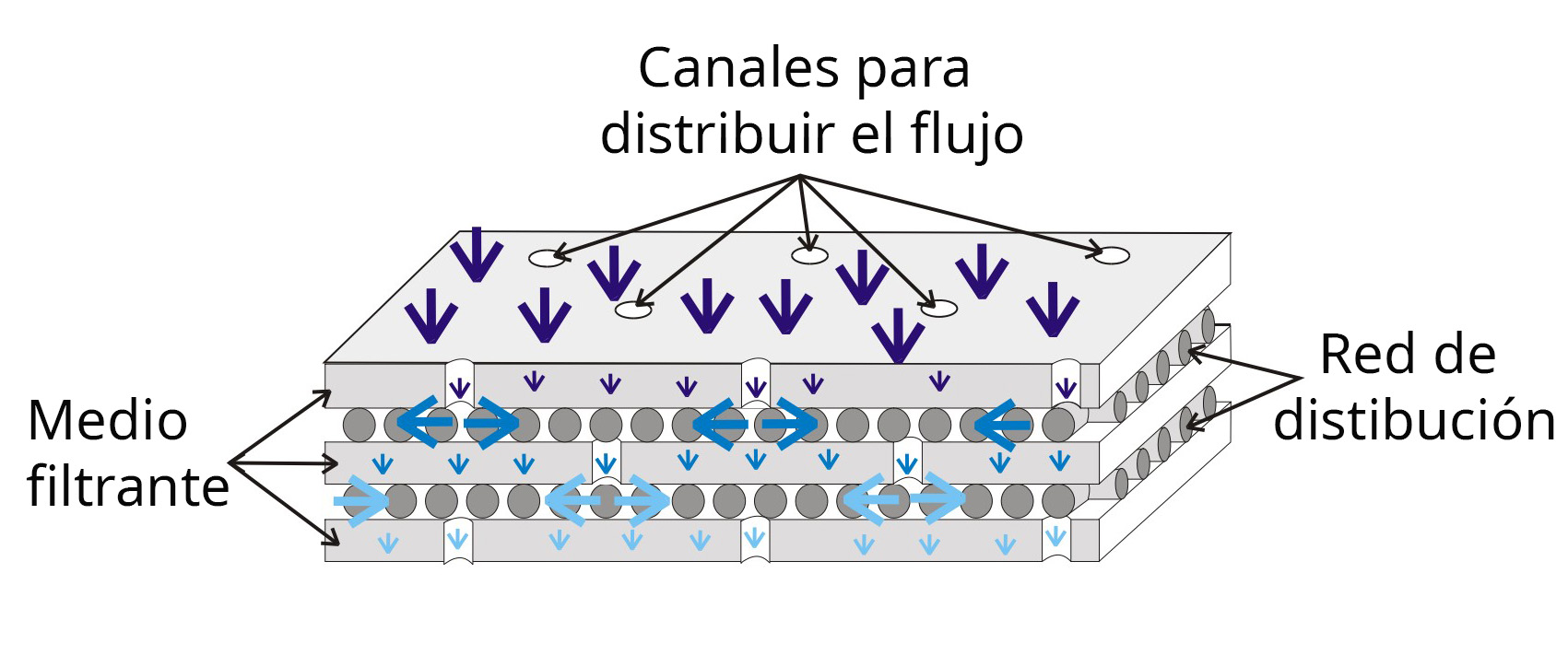

The Betapure NT-T cartridge construction combines a polypropylene media with a mesh that distributes the fluid to form multiple layers. Strategically placed media flow channels allow for greater fluid movement from layer to layer. These media/netting layers combine to form the filter cartridge.

These polypropylene depth filter cartridges offer superior service life, with up to 3 times the dirt holding capacity of competing filters. They are compatible with a wide range of chemicals and temperatures, and are available in rating ranges from 0.5 to 70 microns absolute.

These polypropylene depth filter cartridges offer superior service life, with up to 3 times the dirt holding capacity of competing filters. They are compatible with a wide range of chemicals and temperatures, and are available in rating ranges from 0.5 to 70 microns absolute.

Filtration degree in absolute microns

| Specific pressure drop (in 10″ cartridge) | |||

| Grade elimination | Absolute microns | psid / gpm / cps | mbar / lpm / cps |

| T005 | 0.5 | 4.5 | 81.9 |

| T010 | 1 | 2.5 | 45.5 |

| T020 | 2 | 0.87 | 15.9 |

| T030 | 3 | 0.44 | 8 |

| T050 | 5 | 0.32 | 5.9 |

| T100 | 10 | 0.14 | 2.5 |

| T200 | 20 | 0.065 | 1.2 |

| T300 | 30 | 0.05 | 0.91 |

| T400 | 40 | 0.042 | 0.76 |

| T500 | 50 | 0.029 | 0.52 |

| T700 | 70 | 0.025 | 0.45 |

Specific aqueous pressure drop at room temperature for an equivalent cartridge length of 10″. For multiple cartridge lengths, divide the total flow rate by the number of equivalent lengths. For liquids other than water, multiply the specific pressure drop value given in the table by the viscosity in centipoise.

Absolute filtration ranges

- Beta β 1000 (99.9%)

- Consistent over the life of the filter

Advantages of 3M Betapure NT-T Absolute filter cartridges

- Absolute Filtration: The Betapure NT-T filter cartridge guarantees absolute rated filtration, which means that it retains particles of a specific size with an efficiency of 99.9% or higher, ensuring the quality and purity of the final products.

- Long service life: Thanks to its high-quality design and materials, the Betapure NT-T Absolute cartridge offers a long service life, reducing replacement frequency and operating costs.

- Reduced filtration costs: By providing efficient and durable filtration, the Betapure NT-T Absolute cartridge contributes to a significant reduction in total filtration costs over time.

- Rugged construction: The Betapure NT-T Series design, of which the Betapure NT-T Absolute filter cartridge is a part, is constructed of tough, durable materials, making it ideal for demanding applications and industrial environments.

- Wide range of applications: Betapure NT-T Absolute filter cartridge is versatile and can be used in a variety of industries and applications, including chemical processing, food and beverage, electronics, industrial coatings and more.

- Standards compliance: The performance of the Betapure NT-T Absolute cartridge meets the quality standards and regulations applicable in various industries, ensuring compliance with current regulations.

- Protection of sensitive equipment: In electronic and processing applications, where the presence of contaminants can be detrimental to sensitive equipment and products, Betapure NT-T Absolute cartridge acts as an effective barrier.

- Process Optimization: The reliable and efficient filtration provided by the Betapure NT-T Absolute cartridge contributes to process improvement, product quality consistency and reduced downtime.

Absolute classification performance enables consistent filtration quality and superior particle retention even as differential pressure increases.

These Betapure NT-T Series cartridges are ideal for a wide range of applications, such as chemical, food and beverage, fine chemicals, coatings and industrial applications. They offer superior service life, lower pressure drop and consistent performance compared to equivalent polypropylene depth filters. In addition, they reduce overall filtration costs by requiring fewer cartridges and filter changes.

In summary, the Betapure NT-T Series filter cartridges from 3M Purification Inc. are a leading choice in filtration performance. Their innovative design, long service life and consistent performance make them a reliable and cost-effective solution for a wide range of filtration applications.

Betapure NT-T Series Filter Applications

The Betapure NT-T Series construction provides benefits to customers in a wide range of filtration applications in a variety of end uses. High quality filtration, coupled with reductions in the total cost of filtration, are very attractive benefits for customers in a variety of industries.

Chemical processing and hydrocarbons

Cost reduction is the most critical issue in the production of high quality chemicals, petrochemicals and hydrocarbon processing. The use of Betapure NT-T Series filters in demanding applications requiring absolute rated performance provides long service life, the consistency needed to meet quality standards, and an overall reduction in filtration cost.

- Acids, bleaching agents (sodium hypochlorite)

- Polyethylene and polypropylene manufacturing

- Amine desulfurization and water injection

Food and beverage applications

The growing importance that consumers place on product quality, as well as increasing government regulation, are driving today’s food and beverage industry to ever finer levels of filtration. Betapure NT-T Series filter cartridges meet this challenge throughout their service life.

- Reduction of particulates and turbidity in bottled water

- Protection of reverse osmosis membranes and spray nozzles

- Diatomaceous earth or fine charcoal trap

- Mixing of beverage, rinse and wash water

Fine chemicals and electronics

Betapure NT-T Series filters, with their filtration matrix, are ideal for electronic applications where there is a heavy contaminant load and efficient, long-lasting filtration is required. The combination of all-polypropylene construction and filter media provides the perfect filtration device for use in wafer fabrication and semiconductor device manufacturing. Applications include:

- Pre-reverse osmosis filtration of high sediment density incoming water

- Filtration of copper baths for printed circuit boards

- Color screen filtration for CRT production

Coatings

Betapure NT-T Series filter cartridges are suitable for the filtration of high solids coatings, where they provide superior service life by selectively removing large unwanted particles from the coating and allowing smaller desired particles to pass through. Betapure NT-T Series applications include:

- Film and paper coatings

- Photographic film

- Lens coatings

- High-quality can coatings, paints and inks

Industrial

Betapure NT-T Series filter cartridges are ideal for higher dirt loads due to the flow characteristics and long service life that provide a reduction in overall filtration costs. Betapure NT-T Series cartridges are used in a wide range of general industrial applications including:

- Lubrication of machine tools, chemicals, detergents and waste water

- Textiles, electroplating baths

- Pulp and paper

- Process water and groundwater remediation

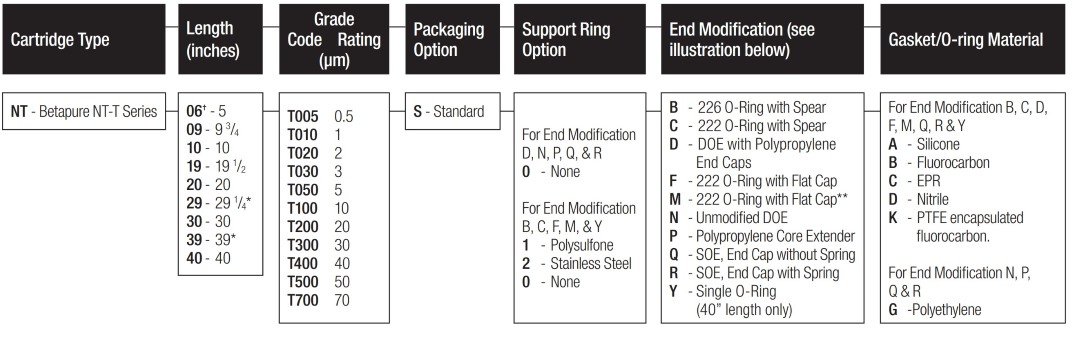

Configuration guide for choosing the right cartridge

Requires N-end modification for use on CT101 (PN 44860) only.

* Applies only to D, N and P end modifications.

** For use with 1ZMP housing.

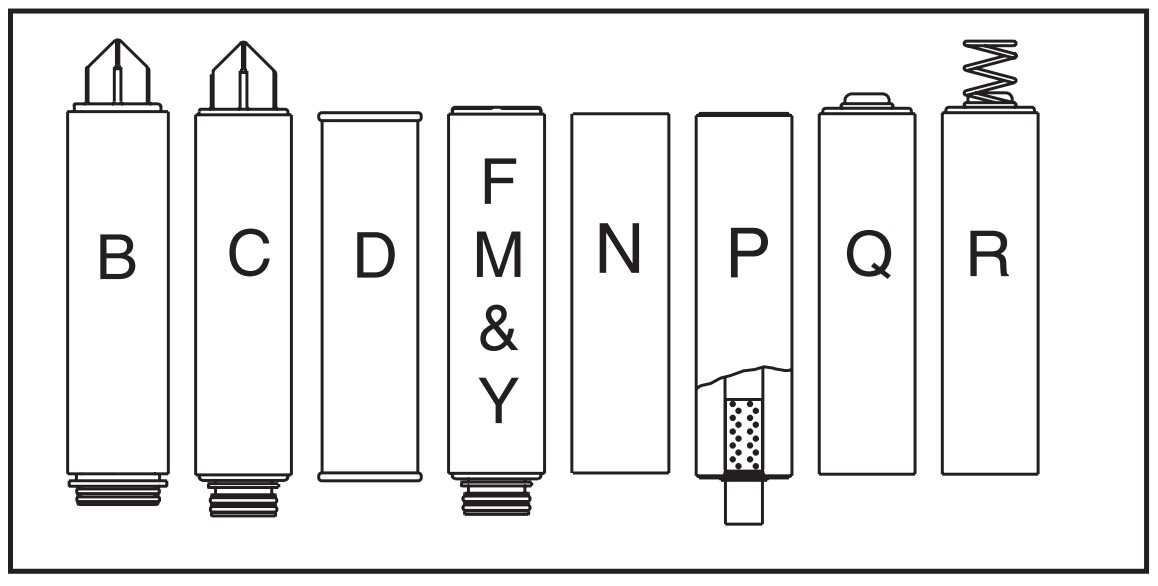

Cartridge terminations, spearhead, double open DOE,