Description

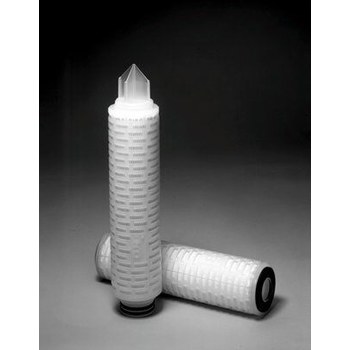

Parker MegaBond™ Nominal Melt Blown Filter Cartridges

The MegaBond™ Nominal (MBN) high purity filter cartridge stands out as an affordable option in the market for this type of filter cartridges. They are designed with a progressive matrix of homogeneous polypropylene fibers that ensures effective filtration for various fluids and liquids. They do not produce extractables by avoiding finishes on the fibers, as well as surfactants that can generate foam and/or extractables.

Technical information

Nominal ratings (micron): 0.5 µm, 1 µm, 5 µm, 10 µm, 25 µm, 50 µm and 75 µm.

Length (Inches): 9-3/4″, 10″, 20″, 30″, 29-1/4″, 30″ and 40″.

Outside diameter: 2 7/16 inches

End cap configuration: Includes options such as 222 O-Ring/Flat, jointless DOE, open end/closed end with polypropylene spring and others.

Gasket material: Buna-N, EPR, Viton, among others.

Structural integrity and material purity

The fiber matrix obtained by Melt Blown of the MegaBond high purity filter ensures that the cartridge body has a stable structural construction in a single component, which facilitates both its compatibility and disposal. In addition, it has no surface finishes, thus avoiding the generation of foam and maximizing the purity of the fluid.

Filtration efficiency and consistency

The excellent bonding between the layers of the Parker MegaBond filter cartridge body prevents particle migration and channel formation, which maintains the integrity of the filtration process. Likewise, the highly uniform fiber size ensures the performance and consistency of the filtration process.

Compatibility and versatility in applications

All components used in their manufacture are recognized by the FDA as suitable for contact with potable and edible liquids, in compliance with CFR Title 21 guidelines. Models are also available in FDA-grade polypropylene that comply with ANSI/NSF61 standards.

MegaBond™ high purity filter applications.

MegaBond™ Nominal high purity filter cartridges represent an economical and efficient solution for the purification of a wide range of industrial fluids such as bottled water and tequila. Designed with a graded density matrix of polypropylene fibers, these cartridges ensure consistent, high quality filtration free of contaminants and undesirable effects such as foaming.

See MegaBond™ high purity filter cartridges table.

Display all models ⬇️

Products |

Micron Rating (µm) |

Length (inch) |

End Cap Configuration |

Seal Material |

MBN05M30 |

0.5 |

30 |

DOE without gaskets |

None |

MBN05M30-TC-E |

5 |

30 |

222 O-Ring/Flat |

EPR |

MBN10M10 |

10 |

10 |

DOE without gaskets |

None |

MBN10M10-TC-E |

10 |

10 |

222 O-Ring/Flat |

EPR |

MBN10M20 |

10 |

20 |

DOE without gaskets |

None |

MBN10M20-TC-N |

10 |

20 |

222 O-Ring/Flat |

Buna-N |

MBN10M29-4 |

10 |

29-1/4 |

DOE without gaskets |

None |

MBN10M29-4-OB |

10 |

29-1/4 |

Open end/Polypropylene spring closed end |

None |

MBN10M30 |

10 |

30 |

DOE without gaskets |

None |

MBN10M30-SF-E |

10 |

30 |

226 O-Ring/Flat |

EPR |

MBN10M40 |

10 |

40 |

DOE without gaskets |

None |

MBN10M40-TC-E |

10 |

40 |

222 O-Ring/Flat |

EPR |

MBN10M40-TC-N |

10 |

40 |

222 O-Ring/Flat |

Buna-N |

MBN10M40-TF-S |

10 |

40 |

222 O-Ring/Fin |

S7442 |

MBN10M9-4 |

10 |

9-3/4 |

DOE without gaskets |

None |

MBN1M10 |

1 |

10 |

DOE without gaskets |

None |

MBN1M20 |

1 |

20 |

DOE without gaskets |

None |

MBN1M20-TC-S |

1 |

20 |

222 O-Ring/Flat |

S7442 |

MBN1M29-4 |

1 |

29-1/4 |

DOE without gaskets |

None |

MBN1M29-4-SF-E |

1 |

29-1/4 |

226 O-Ring/Flat |

EPR |

MBN1M30 |

1 |

30 |

DOE without gaskets |

None |

MBN1M30-SF-N |

1 |

30 |

226 O-Ring/Fin |

Buna-N |

MBN1M30-SF-S |

1 |

30 |

226 O-Ring/Fin |

S7442 |

MBN1M40 |

1 |

40 |

DOE without gaskets |

None |

MBN1M40-OB |

1 |

40 |

Open end/Polypropylene spring closed end |

N/A |

MBN1M9-4 |

1 |

9-3/4 |

DOE without gaskets |

None |

MBN25M10 |

25 |

10 |

DOE without gaskets |

None |

MBN25M10-TC-N |

25 |

10 |

222 O-Ring/Flat |

Buna-N |

MBN25M19-4 |

25 |

19-1/2 |

DOE without gaskets |

None |

MBN25M20 |

25 |

20 |

DOE without gaskets |

None |

MBN25M20-TC-V |

25 |

20 |

222 O-Ring/Flat |

Viton |

MBN25M30 |

25 |

30 |

DOE without gaskets |

None |

MBN25M30-SC-E |

25 |

30 |

226 O-Ring/Flat |

EPR |

MBN25M40 |

25 |

40 |

DOE without gaskets |

None |

MBN25M40-TC-E |

25 |

40 |

222 O-Ring/Flat |

EPR |

MBN25M40-TC-S |

25 |

40 |

222 O-Ring/Flat |

S7442 |

MBN25M9-4 |

25 |

9-3/4 |

DOE without gaskets |

None |

MBN50M10 |

50 |

10 |

DOE without gaskets |

None |

MBN50M20 |

50 |

20 |

DOE without gaskets |

None |

MBN50M20-TC-E |

50 |

20 |

222 O-Ring/Flat |

EPR |

MBN50M30 |

50 |

30 |

DOE without gaskets |

None |

MBN50M40 |

50 |

40 |

DOE without gaskets |

None |

MBN50M40-TC-V |

50 |

40 |

222 O-Ring/Flat |

Viton |

MBN5M10 |

5 |

10 |

DOE without gaskets |

None |

MBN5M10-DO-N |

5 |

10 |

DOE with gaskets/collars |

Buna-N |

MBN5M10-TC-N |

5 |

10 |

222 O-Ring/Flat |

Buna-N |

MBN5M10-TF-N |

5 |

10 |

222 O-Ring/Fin |

Buna-N |

MBN5M19-4 |

5 |

19-1/2 |

DOE without gaskets |

None |

MBN5M20 |

5 |

20 |

DOE without gaskets |

None |

MBN5M20-TF-S |

5 |

20 |

222 O-Ring/Fin |

S7442 |

MBN5M29-4 |

5 |

29-1/4 |

DOE without gaskets |

None |

MBN5M29-4-TF-N |

5 |

29-1/4 |

222 O-Ring/Fin |

Buna-N |

MBN5M30 |

5 |

30 |

DOE without gaskets |

None |

MBN5M30-SF-E |

5 |

30 |

226 O-Ring/Fin |

EPR |

MBN5M30-TC-V |

5 |

30 |

222 O-Ring/Flat |

Viton |

MBN5M40 |

5 |

40 |

DOE without gaskets |

None |

MBN5M40-OB |

5 |

40 |

Open end/Polypropylene spring closed end |

N/A |

MBN5M40-TB-E |

5 |

40 |

222 O-Ring/Polypropylene spring closed end |

EPR |

MBN5M40-TC-E |

5 |

40 |

222 O-Ring/Flat |

EPR |

MBN5M40-TC-S |

5 |

40 |

222 O-Ring/Flat |

S7442 |

MBN5M40-TF-E |

5 |

40 |

222 O-Ring/Fin |

EPR |

MBN5M9-4 |

5 |

9-3/4 |

DOE without gaskets |

None |

MBN75M20 |

75 |

20 |

DOE without gaskets |

None |