Charcoal is a porous fuel material that has acquired high percentages of carbon due to the absence of air by exposing organic materials to high temperatures. Carbonizing an organic material gives it adsorption properties.

During the carbonization process, volatile elements and water are eliminated. Volatile compounds are chemical substances that can change from a liquid, solid or gaseous state without the application of high temperatures. In the carbonization process to generate charcoal, gases and vapors are released from the raw material in the form of gases and vapors due to heat. Some of these volatiles can be water, carbon dioxide, methane and depending on the feedstock, tar, phenols, aldehydes or ammonia are released. The elimination of these compounds results in a carbon-rich structure.

Main uses of charcoal

The main application of charcoal in the world is as a fuel, it is a solid and dusty solid that has been used as an energy source in different areas, both industrial and domestic.

Among the industrial applications of charcoal is its use as:

Fuel

For the generation of electrical and thermal energy in power generation plants. It is also used as a fuel in the production of steel, cement and other chemical and petrochemical products.

At the domestic and commercial level, charcoal is frequently used as fuel in stoves and barbecues as well as for home heating, thanks to its high calorific capacity and low cost.

However, coal remains a significant source of energy and fuel worldwide, although the use of clean energy sources is increasing. Coal remains the largest source of energy for electricity generation globally due to its abundance, low cost and high energy content. However, efforts are being made to reduce and eliminate the use of coal due to its significant contribution to air pollution and greenhouse gas emissions.

Activated Carbon

Charcoal can be converted to activated carbon through a process called activation. Activated carbon is manufactured by heating charcoal in the presence of controlled oxygen and high temperature, which causes the charcoal to develop a large number of internal pores. These pores provide the activated carbon with a large surface area, which increases its natural adsorption capacity and gives it properties for purification and treatment of organic compounds.

How is charcoal made?

1. DRYING

In this initial phase, the raw material is dried to eliminate most of the moisture present in it. Pre-drying is necessary to reduce the amount of energy required to reach carbonization temperatures and to avoid excessive steam formation that could adversely affect pore formation in the coal.

2. EXPULSION OF VOLATILES

As the temperature increases, volatile components, such as water, gases and organic compounds, begin to be released from the feedstock. These components evaporate and can be captured and removed through gas capture systems or distillation processes.

3. CARBONIZATION

In this phase, the remaining organic matter is thermally decomposed and converted into solid carbon. Temperature and the absence of oxygen are critical at this stage. Chemical bonds in organic compounds are broken and a carbonized structure is formed.

4. COOLING AND EXTRACTION

Once carbonization is complete, the resulting charcoal is gradually cooled. It is then removed from the kiln or carbonization chamber. The final product is charcoal, which is lighter and more porous compared to the original raw material.

5. ADDITIONAL TREATMENTS

In some cases, charcoal may undergo additional treatments, such as chemical or physical activation. Activation further increases the porosity and adsorption capacity of the carbon.

6. FORMATION OF PORES

During activation, the internal structure of matter reorganizes, forming a porous structure. Volatile component removal and pore formation are interrelated processes, and the quality of porosity is a key factor in the effectiveness of carbon for adsorption and purification.

Differences between charcoal and mineral coal

Criteria |

Charcoal |

Mineral coal |

|---|---|---|

Origin and formation |

It is formed from the carbonization of organic matter such as wood, coconut shells, hard shells of nuts and peanuts or pits of fruits such as apricots, olives and peaches. The process involves heating the feedstock in the absence or with limited amounts of oxygen. High temperatures break down organic matter into carbon and other elements, forming charcoal. |

It is formed from the accumulation and decomposition of organic plant matter in swampy areas and marshes over millions of years. Over time, the accumulation of organic matter is subjected to increasing pressures and temperatures, gradually transforming into charcoal as the volatile components are removed. Some mineral coals contain ground compounds such as sulfur, metals and other undesirable compounds. |

Carbon content |

It has a lower carbon content compared to mineral coal. It may also contain other elements such as hydrogen, oxygen and nitrogen due to its formation at lower temperatures. |

It has a higher carbon content and is more energetic due to its formation over longer geological periods. The geological process of transformation into coal increases the carbon content and reduces the other elements present. |

Uses and applications |

It is used in energy applications in domestic heating, outdoor cooking, industrial power generation and water purification when chemically or thermally activated. It is also used in agriculture to improve soil quality and retain nutrients. |

It is a large-scale primary energy source. It is used in power generation, steel production, industrial processes and heating in central heating systems. It can also be activated for water and gas treatment. |

Environmental impacts |

Although it has a relatively lower environmental impact than coal, its production can contribute to deforestation and ecosystem degradation if not managed sustainably. |

It has significant environmental impacts due to the release of carbon dioxide and other pollutants during burning. Coal mining can also cause damage to the landscape, biodiversity and water resources. |

Physical fitness |

It tends to have a more irregular and fragmented shape compared to coal. |

It can be found in various forms, including anthracite, hard coal, lignite and peat, with different degrees of maturity and carbon content. |

Activated charcoal

Charcoal activation is a process in which charcoal is treated to increase its surface area and adsorption properties. The activation process involves subjecting the carbon to high temperatures and, in some cases, to the presence of certain gases or chemicals, which creates a porous structure in the material. This porous structure increases the carbon’s ability to adsorb molecules and particles on its internal surface.

There are two main methods of charcoal activation: physical activation and chemical activation.

Physical activation:

In physical activation, charcoal is heated to high temperatures in the absence of air or with a limited amount of oxygen. This process causes the thermal decomposition of the organic components of the coal and leads to the formation of pores in its structure. The increase in temperature and exposure to certain gases during this process will determine the size and shape of the pores in the resulting activated carbon.

Chemical activation:

Chemical activation involves the use of chemical agents, such as acids and bases, together with high temperatures, to create the porous structure in charcoal. These chemical agents break down certain components of the carbon and contribute to the formation of pores.

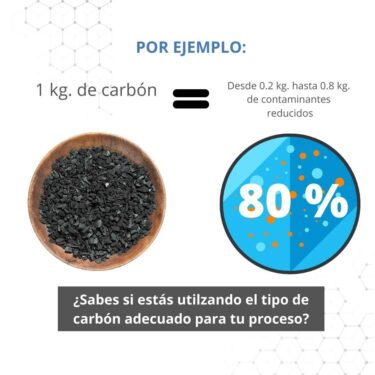

The activation process can be tightly controlled to achieve different characteristics of the activated carbon, such as pore size, adsorption capacity and adsorption selectivity for certain compounds. The resulting activated carbon is used in a variety of applications, such as water and air purification, pollutant removal, adsorption of toxins in cases of poisoning, and more.

It is important to note that the activation process may vary depending on the type of plant material used to create the activated carbon, as well as the specific parameters used during activation (temperature, time, chemical agents, etc.). These factors will influence the final properties of the activated carbon and its ability to perform certain functions.

What is activated charcoal used for?

Water and air purification:

Activated charcoal is used in water treatment and purification systems to remove contaminants, chemicals and undesirable tastes from drinking water and air.

Detoxification:

In medicine and emergency medicine, activated charcoal is used to treat poisoning and overdose, as it can adsorb certain poisons and toxins in the digestive tract before they are absorbed by the body.

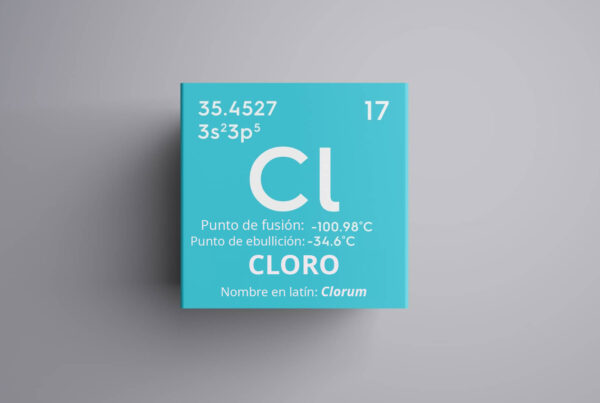

Gas treatment:

In industry, activated charcoal is used in gas and air purification systems to remove volatile organic compounds and toxic gases.

Odorization:

Due to its ability to adsorb odors, activated carbon is used in products such as air purifier filters, air conditioning filters and deodorant products.

Food industry:

In the food industry, activated charcoal is used as a bleaching and purification agent for certain foods, such as sugar and vegetable oils.

Pharmaceutical industry:

In addition to its use in cases of poisoning, activated carbon is used in the manufacture of drugs to improve the adsorption of certain compounds.

Agriculture:

Activated charcoal can improve water and nutrient retention in the soil, as well as improve soil quality and its ability to retain nutrients in agriculture.

Elimination of color and flavor:

In the food and beverage industry, activated carbon is used to remove unwanted colors and flavors from products such as spirits.

Wastewater treatment:

In wastewater treatment, activated charcoal can be used to remove contaminants and chemicals before the water is used. But in this particular case mineral activated carbon has a better performance.

Coconut shell activated charcoal.

At Carbotecnia we have coconut shell activated carbons that are first washed and dried. After carbonization, the activation process is carried out by means of high temperature steam.

One of its outstanding applications lies in the effective removal of both taste and color from water sources. In addition, coconut shell-derived activated carbon is highly effective in the process of clarifying water used in industrial applications. In the industrial field, water is often subjected to specific treatments to ensure its suitability for various processes.

Activated carbon obtained from coconut shells stands out as a high quality adsorbent due to its large surface area (240 – 280 m²/g), remarkable mechanical strength and hardness, as well as its low content of fine particles.

-

Micro K Coconut shell activated carbon

Add to quote -

Micro 4 LF Coconut shell activated carbon free of fines

Add to quote -

Vapomer – Activated Carbon for Mercury Vapors

Add to quote -

Vapamon – Activated carbon for ammonia and amines

Add to quote -

Carvapox – Activated carbon for alcohol, aldehyde and alkene vapors

Add to quote -

Carvacid – Activated carbon for acid and organic gases

Add to quote -

Vapacid – Activated carbon for acid gases

Add to quote -

Carvapur 40 – Activated Carbon for Organic Gases

Add to quote -

Micropol 4 200 – Coconut shell powdered activated carbon

Add to quote -

Biostat – Bacteriostatic activated carbon

Add to quote -

Micro 4 LS – Solubles-free granular activated carbon from coconut shells

Add to quote -

Micro 4 Activated carbon for water purification

Add to quote

Wood activated charcoal.

Wood-derived activated carbon is produced from natural sources such as sawdust, pine wood and bamboo. This type of activated carbon finds multiple applications in various industries. For example, it is widely used in the chemical industry to treat colored water, in the oil industry for the desulfurization of refinery furnaces, in the sugar industry to remove ash and volatiles, and in the pharmaceutical field for the removal of drug degradation products, among other fields of application.

Sources:

Reinares Coal: https://carbonesreinares.es