Description

Granular activated carbon to adsorb mercury vapors.

Raw material: Coconut shell

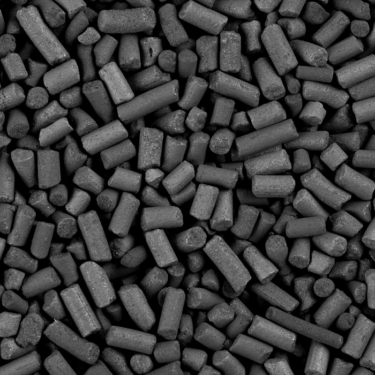

Particle size range (mesh): 4×10, 8×14, 14×30, or 4 mm pellet.

Packing: 25 kg bags, 100 kg bags, 100 kg quads

Applications:

Cartridge respirators (face masks)

Control of specific gaseous contaminants in vents and enclosed spaces with mercury vapors.

Emissions of mercury vapors are a problem in processes that use this metal. Such processes include some foundries, the manufacture of certain types of electrical equipment, chlorine production plants using mercury cells, and many others.

In order to provide a practical and economical solution to this problem, Vapomer, a specially impregnated carbon for the retention of mercury vapor in gaseous streams, was designed.

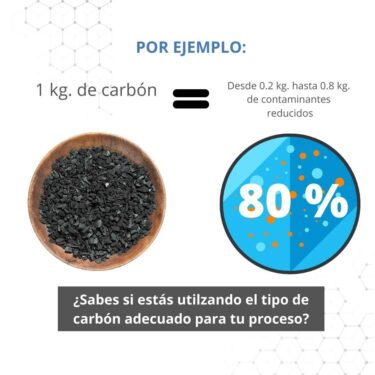

Vapomer retains mercury vapors, even in streams with high humidity. The retention capacity of this product is about 0.3 kg of mercury per kg of carbon. The gaseous stream in the Vapomer bed should have a surface velocity between 6 and 12 m/min. The empty bed contact time is typically between 8 and 20 seconds, depending on the initial mercury concentration, the maximum allowable final concentration and the operating time of the carbon bed before it must be changed.

Vapomer is most efficient at high temperatures, as long as these are not higher than 100 °C. Once the practical adsorption capacity of this carbon has been exhausted.

Mercury is a trace element found in natural gas.

Mercury is harmful to the environment and to processes and transport equipment. Natural gas requires treatment to prevent the negative implications associated with the presence of this substance.

Our activated carbons’ high removal efficiency, low pressure drop and high hardness make it the superior technology for mercury removal.