Description

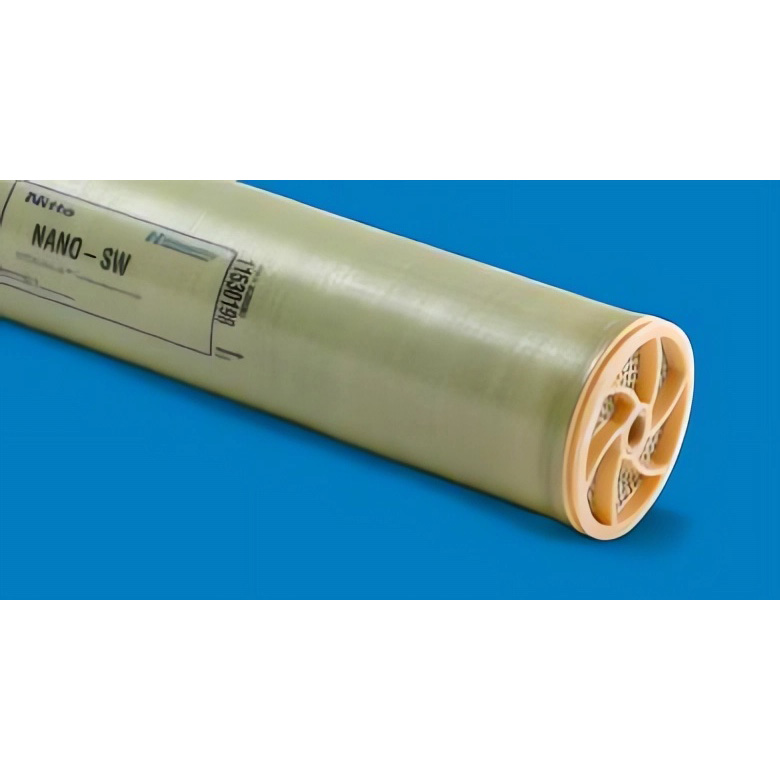

HSRO-390-FF 8″ FilmTec DOW membrane: Reverse osmosis disinfectable with hot water.

Discover DuPont (Dow) FilmTec HSRO-390-FF 8″ x 40″ membrane, a heat disinfection reverse osmosis (HSRO) element that offers high purity water and resistance to hot water disinfection. This feature reduces the use of chemical disinfectants and saves operating costs in applications such as sterile water for injection and dialysis.

Manufactured with advanced automated equipment, the HSRO-390-FF membrane features a high active membrane area, allowing system designers to opt for a lower operating flux to minimize fouling or achieve desired performance with fewer membrane elements, saving costs and reducing the systems footprint. In addition, its full-fit design minimizes stagnant areas, which is optimal for applications requiring a sanitary design.

All components of the HSRO-390-FF membrane meet U.S. Food and Drug Administration (FDA) standards. The elements are available in wet and dry versions.

Take advantage of the benefits and applications of the FilmTec HSRO-390-FF membrane in the production of sterile water for injection, dialysis and other applications requiring high purity water and heat disinfection. Choose DuPont for innovative and efficient reverse osmosis solutions to improve water quality in your projects.

8″ HSRO-390-FF Membrane Applications

- Evaporator condensate polishing

- Sanitary applications

- Water for microelectronics

- Sulfate removal in injectable water

- Offshore oil platforms

- Products for use in medical applications

Advantages of HSRO-390-FF membrane

- High flow range

- Full-fit design

- Consistent quality thanks to automated winding

Key features

- It provides excellent water quality with the added ability to resist disinfection with hot water, eliminating the need for chemical disinfectants.

- High active membrane area allows the design of systems with lower operating flux or cost savings by using fewer membrane elements.

- Full-fit configuration design minimizes stagnant areas, ideal for sanitary, evaporation and medical applications.

- All components comply with Food and Drug Administration (FDA) standards.

Typical properties |

FilmTec™ element part number |

Active area ft² (m²) |

Stabilized permeate flow rate gpd (m³/d) |

Minimum salt rejection |

|---|---|---|---|---|

HSRO-390-FF |

170701 |

390 (36) |

14,500 (55) |

97 |

- Permeate flow and salt rejection are based on the following test conditions: 2,000 ppm NaCl, 150 psi (10.3 bar), 77°F (25°C), pH 8 and 15% recovery prior to any heat treatment.

- Permeate flow rates for individual elements can vary by ±20%.

- Sales specifications may vary as design revisions are made.

FilmTec™ element |

Feed pressure psi (bar) |

Average flow rate gfd (lmh) |

Calculated permeate flow rate gph (m³/h) |

Recovery (%) |

Feed TDS (ppm NaCl) |

Calculated permeate TDS (ppm) |

Calculated rejection (%) |

|---|---|---|---|---|---|---|---|

HSRO-390-FF |

130.5 (9) |

15 (26) |

4,490 (17) |

75 |

5,000 |

13.2 |

97.4 |

- The results are based on WAVE modeling after heat treatment of a 2-stage (2:1) system with a 6-element pressure vessel, operated at 77ºF (25ºC), pH 7, feed flow of 6,000 gph (22.7 m³/h) and a Flow Factor of 0.85.

- WAVE version: contact your DuPont representative for further assistance with projections.

- No warranty is provided for the application of this information, as conditions of use and applicable laws may vary from place to place and may change over time.

- Pilot testing will provide the best performance approach for any specific application.

Product Category

FilmTec elements especially 8

FilmTec Specialty 8″ elements have been developed through industry-leading research to meet special requirements.