Description

Manual cleaning disc filter LCM Series

| Model | Max. flow rate Liters/min | Number of filters | Connection diameter NPT | Connection type | HDPE Manifold Diameter |

|---|---|---|---|---|---|

| 202 / 3FH | 1000 | 2 | 2″ | Flange | 4″ – 110 |

| 202 / 3VH | Clamp | ||||

| 203 / 4FH | 1500 | 3 | 2″ | Flange | |

| 203 / 4VH | Clamp | ||||

| 204 / 6FH | 2000 | 4 | 2″ | Flange | 6″ – 160 |

| 204 / 6VH | Clamp | ||||

| 205 / 6FH | 2500 | 5 | 2″ | Flange | |

| 205 / 6VH | Clamp | ||||

| 206 / 6FH | 3000 | 6 | 2″ | Flange | 6″ – 160 |

| 206 / 6VH | Clamp | ||||

| 207 / 8FH | 3500 | 7 | 2″ | Flange | 8″ – 200 |

| 208 / 8FH | 4000 | 8 | 2″ | Flange | 8″ – 200 |

In the slotted disc line, the filtering elements are high density polyethylene collectors.

Some applications:

- Industrial water filters

- Purificación de agua

- Water Treatment Plants

- Agricultural drip irrigation

- Process water filtration

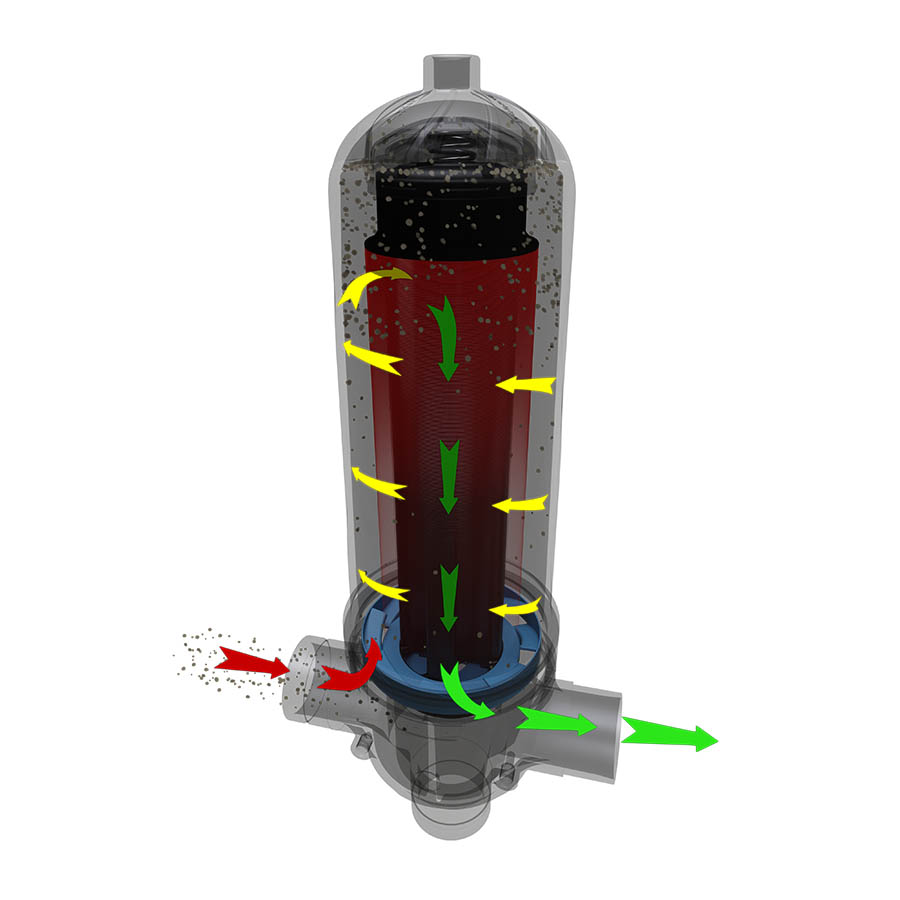

AZUD HELIX System.

The Helix system generates a turbine-like flow that spins the water to prevent premature clogging of sediment in the filter. Optimizes performance and minimizes the frequency and intensity of maintenance work.

Manual cleaning disc filter.

The LCM allows the use of both manual element filtering and DF-DISC.

Modular systems to add more filters and increase flow. The system allows a wide range of possibilities with a minimum number of components.

Made of technical plastic.

Low maintenance. No tools required.

Maximum resistance with moving parts not susceptible to wear due to continuous operation.

SPECIFICATIONS:

Reflows from AZUD HELIX LCM equipment without any interruption of the water supply to the crop. Backwashing is sequential:

One filter is in the backwashing stage while the rest of the equipment is in the filtration stage, supplying water to the facility.

STAGE FILTRATION: The propeller generates a centrifugal helical effect that moves away from the discs the particles in the water. This translates into less frequent and less intensive maintenance, thus saving water. The deep filtration process is carried out through the discs. Water Flow STAGE: When the operator change the position of the two manually activated backwash valves the filtered water enters the filter in the opposite direction through the structure of the filter element. The solids previously retained during the filtration stage are expelled from the discs and discharged out through the collector drain.