Description

The automatic deep-bed multimedia filter with automatic valve

It is a multimedia filter recommended for domestic or commercial use, and operation of less than 23 hours.

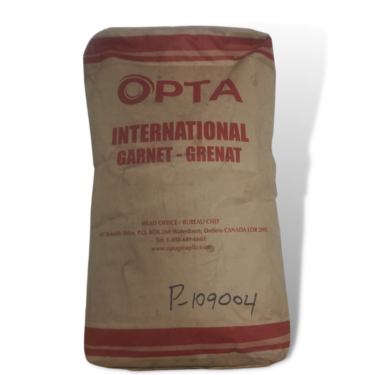

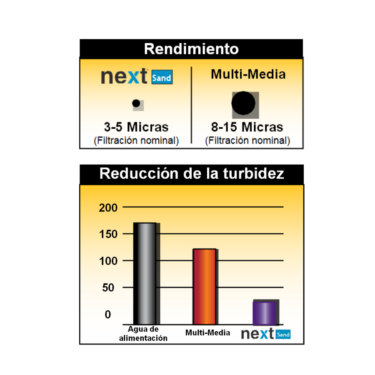

With this filter, a solids filtration efficiency of between 5-10 microns can be obtained. This is achieved by placing the granular media in such a way that the size of the void spaces (pores) decreases along the depth of the multimedia filter. The largest particles are captured by anthracite number one with an effective size (E.T.) of 0.85 – 0.95 mm. The remaining particles that make it past the anthracite bed are captured by the 16 x 35 U.S. Std. silica sand bed. Mesh with an E.T. of 0.44 – 0.52 mm, and finally the garnet bed number 30 – 40 with an E.T. of 0.33 – 0.37 mm.

The media used in this filter is a combination of ¼ x ⅛ U.S. Std. silica gravel. Mesh and garnet number 8-12 is placed on top of the silica gravel bed, this material is called high density gravel. This arrangement is necessary because garnet 30 – 40 is a denser material than silica gravel. Failure to place the high-density gravel causes the garnet from the bottom bed and the silica gravel to mix when backwashing.

The granular media used in Carbotecnia multimedia loading are carefully selected in accordance with the quality parameters specified by AWWA in standard B-100.

Automatic filters with standard electromechanical valves (Aquatrol):

Code |

Tank size (in) |

Bed volume(ft3) |

Normal service flow (lpm) |

Normal service flow (gpm) |

Maximum service flow (lpm) |

Maximum service flow (gpm) |

Backwash flow (lpm) |

Backwash flow (gpm) |

Automatic Valve (Aquatrol) |

Input/Output Connections |

Connections Drainage |

|---|---|---|---|---|---|---|---|---|---|---|---|

P_610023 |

8×44 |

0,75 |

8 |

2,1 |

10,6 |

2,8 |

26,5 |

7 |

AQT-275FT-NX |

1″ |

¾” |

P_610024 |

9×48 |

1 |

10 |

2,6 |

13,3 |

3,5 |

34,07 |

9 |

AQT-275FT-NX |

1″ |

¾” |

P_610025 |

10×54 |

1,5 |

12 |

3,3 |

16,7 |

4,4 |

37,85 |

10 |

AQT-275FT-NX |

1″ |

¾” |

P_610026 |

12×52 |

2 |

18 |

4,7 |

23,9 |

6,3 |

56,78 |

15 |

AQT-275FT-NX |

1″ |

¾” |

P_610027 |

13×54 |

2,5 |

21 |

5,5 |

27,9 |

7,4 |

71,92 |

19 |

AQT-275FT-NX |

1″ |

¾” |

P_610028 |

14×65 |

3 |

24 |

6,4 |

32,4 |

8,6 |

83,27 |

22 |

AQT-275FT-NX |

1″ |

¾” |

P_610029 |

16×65 |

4 |

32 |

8,4 |

42,4 |

11,2 |

109,77 |

29 |

AQT-285FT-NX |

1 ½” |

1″ |

P_610030 |

18×65 |

5 |

40 |

10,6 |

53,6 |

14,2 |

140,05 |

37 |

AQT-285FT-NX |

1 ½” |

1″ |

P_610031 |

21×62 |

7 |

55 |

14,5 |

73 |

19,3 |

166,54 |

44 |

AQT-285FT-NX |

1 ½” |

1″ |

P_610032 |

24×72 |

10 |

71 |

18,8 |

95,1 |

25,1 |

227,1 |

60 |

AQT-315FT-NX |

2″ |

2″ |

P_610033 |

30×72 |

15 |

112 |

29,5 |

148,7 |

39,3 |

378,5 |

100 |

AQT-315FT-NX |

2″ |

2″ |

Automatic filters with premium digital valves (Clack):

Code |

Tank size (in) |

Bed volume(ft3) |

Normal service flow (lpm) |

Normal service flow (gpm) |

Maximum service flow (lpm) |

Maximum service flow (gpm) |

Backwash flow (lpm) |

Backwash flow (gpm) |

Automatic Clack Valve |

Input/Output Connections |

Connections Drainage |

|---|---|---|---|---|---|---|---|---|---|---|---|

P_610010 |

8×44 |

0,75 |

8 |

2,1 |

10,6 |

2,8 |

26,5 |

7 |

Clack WS1 |

¾” |

¾” |

P_610011 |

9×48 |

1 |

10 |

2,6 |

13,3 |

3,5 |

34,07 |

9 |

Clack WS1 |

¾” |

¾” |

P_610012 |

10×54 |

1,5 |

12 |

3,3 |

16,7 |

4,4 |

37,85 |

10 |

Clack WS1 |

¾” |

¾” |

P_610013 |

12×52 |

2 |

18 |

4,7 |

23,9 |

6,3 |

56,78 |

15 |

Clack WS1 |

¾” |

1″ |

P_610014 |

13×54 |

2,5 |

21 |

5,5 |

27,9 |

7,4 |

71,92 |

19 |

Clack WS1 |

¾” |

1″ |

P_610015 |

14×65 |

3 |

24 |

6,4 |

32,4 |

8,6 |

83,27 |

22 |

Clack WS1.25 |

1 ¼” |

1″ |

P_610016 |

16×65 |

4 |

32 |

8,4 |

42,4 |

11,2 |

109,77 |

29 |

Clack WS1.25 |

1 ¼” |

1″ |

P_610017 |

18×65 |

5 |

40 |

10,6 |

53,6 |

14,2 |

140,05 |

37 |

Clack WS1.5 |

1 ½” |

1 ½” |

P_610018 |

21×62 |

7 |

55 |

14,5 |

73 |

19,3 |

166,54 |

44 |

Clack WS1.5 |

1 ½” |

1 ½” |

P_610019 |

24×72 |

10 |

71 |

18,8 |

95,1 |

25,1 |

227,1 |

60 |

Clack WS2/QC |

2″ |

2″ |

P_610020 |

30×72 |

15 |

112 |

29,5 |

148,7 |

39,3 |

378,5 |

100 |

Clack WS2H |

2″ |

2 ½” |

P_610021 |

36×72 |

20 |

161 |

42,4 |

214,1 |

56,6 |

529,9 |

140 |

Clack WS3 |

3″ |

3″ |

P_610022 |

42×72 |

30 |

218 |

57,7 |

291,3 |

77 |

757 |

200 |

Clack WS3 |

3″ |

4″ |

*To select the most suitable filter for your needs, you must know the maximum flow rate you require. If you have any doubts about the selection, please contact one of our consultants.

Components of a multimedia filter:

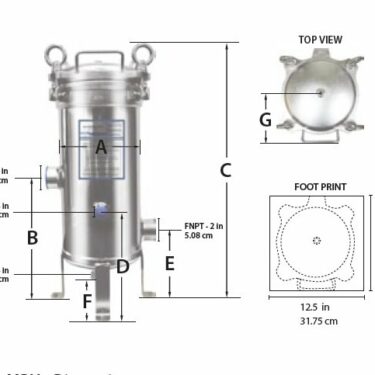

Fiberglass tank: Made of one-piece polypropylene lined with fiberglass for mechanical strength and an inner polyethylene cover. It is maintenance free. Maximum operating pressure 150 psi.

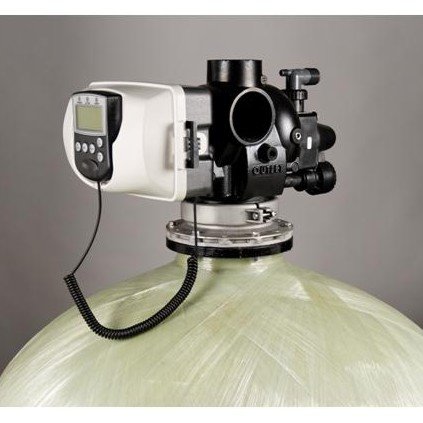

Automatic control valve or head: It is the component that directs the flow through the filter beds, it includes inlet, outlet and drain connections; it allows us to change between the different service or backwashing positions automatically. Maximum operating pressure 125 psi.

Granular filter media: It is a bed made up of anthracite number one with an E.T. of 0.85 – 0.95 mm, silica sand 16 x 35 U.S. Std. Mesh with O.T. of 0.44 – 0.52mm and garnet number 30 – 40 with O.T. of 0.33 – 0.37 mm.

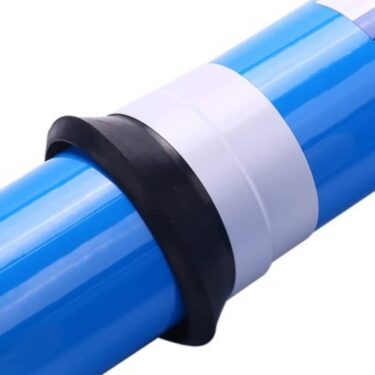

Lower distributor and distribution pipe: The distributor or nozzle is a micro-slotted element, placed at the bottom of the tank, which allows a correct flow distribution in the backwash position, and operates as a physical barrier that does not allow the granular medium to escape to the outlet line in the service position. There are simple, stack type distributors or distributors with lateral tubes, spider type; their selection depends on the service and backwash flow, as well as the diameter of the tank. Its material of construction is HDPE or ABS. The central pipe is a PVC Ced pipe. 40 connecting the lower distributor to the control head or valve.

Backing gravel: 1/8 x 1/16 U.S. Std. silica gravel. Mesh as a support medium. By having a micro-grooved distributor or diffuser, the need to place several gravel beds of different grain size is eliminated.

Advantages |

Applications |

|---|---|

|

|

Multimedia filter operating conditions:

- Input pH: 3-12

- Bed height (in): 30 – 40

- Clearance height for bed expansion (%, min.): 50

- Hydraulic service load (gpm/ft2): 7-10

- Hydraulic backwash load (gpm/ft2): 20 – 22

- Operating pressure: 30 – 100 psi

- Backwash: by pressure differential > 10 psid or by time every 72 hours max.

- Lifetime of granular media: 3 to 5 years

Available configurations:

Simple automatic filter by time: Carbotecnia single tank equipment with dual loading, with automatic control valve for backwashing by time (every certain number of days or on a certain day of the week). Recommended for domestic or commercial use, and operation less than 23 h. When ordering these units with the premium valves (Clack), they have the option of automatic backwashing due to pressure drop (to make use of this configuration, a differential pressure switch must be requested with your sales consultant).

Multiple automatic filters: This configuration is only available for premium valves with industrial control (Clack WS2H and WS3). With this option, up to 16 units can be operated.

- Parallel filters: this option allows all filtration units to operate at the same time, unless a filter in the system is in backwashing stage. This system is programmed in such a way that when one of the filters requires backwashing, either due to time or pressure drop, the backwashing sequence is initiated in series for all the filters in the system, starting with the one that sent the signal.

- Progressive flow filters: this option is ideal when water demand varies and we have peak operating flows at different times of the day. This function consists of setting a flow value at which one or more filters will come into operation in order to meet the required flow. A flow value must be specified for the incorporation of each of the filters in the system.

More information:

How is a deep-bedded bed composed?

What is deep bed filtration?

What is microfiltration?

What are micrometers, microns or microns?

Introduction to sediment filtration in liquids

Filter media for liquids

Selection of a distributor or nozzle for a deep bed filter

Disc filters

Source:

The 3 essential steps for reverse osmosis pretreatment + 1 optional step