Description

Activated carbon for organic gases

Carvapur granular carbon is a highly microporous activated carbon, which has the property of preferentially adsorbing organic molecules with a molecular weight between 55 and 250. Such molecules tend to be volatile, so they are typically present in air and other gases.

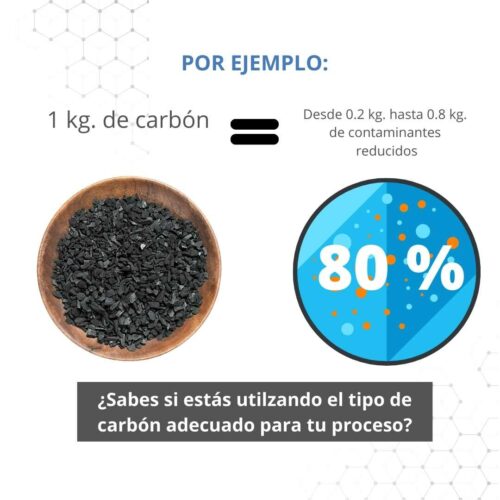

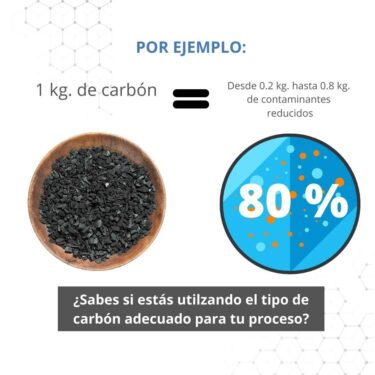

It is manufactured from coconut shell and is thermally activated to obtain an enormous surface area, which gives it a high adsorption capacity. Typically, it retains between 0.2 and 0.8 kg of contaminants per kg of coal. Carvapur has a high hardness and therefore breakage losses during handling are low.

It is recommended that the surface velocity of the air or gas being purified with this carbon be between 10 and 30 m/min, and that the contact time in an empty bed be greater than 0.1 seconds.

Activated carbon to retain organic compounds in air and gases

- Raw material: Coconut shell

- Particle size range (mesh): 4×10, 8×14, 14×30, or 4 mm pellet.

- Packaging: 25 kg sacks, 100 kg bags, 100 kg bags

Applications:

- Cartridge respirators (face masks)

- Paint booths

- Stove hoods

- Solvent recovery

- Compressed air purification (diving tanks and hospitals)

- Industrial contaminant control (such as carbon dioxide, hydrogen, helium, acetylene and carbon monoxide)

- Air conditioning

- Air recirculation.

Compounds retained by activated carbon:

Of the contaminants listed, some are specific chemical compounds. Others represent a class of compounds and others are mixtures of varying composition. The capacity of activated carbon for odors varies with the concentration of odors, as well as with the humidity and temperature of the air.

A = High capacity (coal retains 20% to 50% of its own weight).

B = Satisfactory capacity (retains 10% to 25% of its weight).

C = Sufficient capacity to give good service under particular operating conditions, we recommend testing.

D = Low capacity. Activated carbon does not give adequate service under ordinary operating conditions.

*= A carbon impregnated with a certain substance significantly increases the adsorption capacity of this compound.

Essential oils A

Rancid oils A

Amyl acetate A

Butyl acetate A

Cellosolve A acetate

Ethyl acetate A

Isopropyl acetate A

Methyl cellosolve A acetate

Methyl acetate B

Propyl acetate A

Acetone B

Acetic acid A

Acrylic acid A

Butyric acid A

Caprylic acid A

Carbolic acid A

Lactic acid A

Palmitic acid A

Propionic acid A

Uric acid A

Valeric acid A

Methyl acylate A

Ethyl acrylate A

Acrylonitrile A

Adhesives, A solvents

Masking agents A

Garlic A

Camphor A

Amyl alcohol A

Butyl alcohol A

Valeric Aldehyde A

Tar A

Anesthetics B

Acetic anhydride A

Aniline A

Antiseptics A

Flower scent A

Food flavors A

Aromatizers A

Alcoholic beverages A

Bleaching B

Borano B

Pitch and tar A

Bromine A

Ethyl bromide A

Methyl bromide B

Butadiene B

Butane C

Butyl cellosolve A

Butanone A

Cellosolve A

Cyclohexane A

Cyclohexanone A

Cyclohexene A

Chlorine B

Chlorobutadiene A

Chloroform A

Chlorobenzene A

Chloronitropropane A

Chloropicrin A

Butyl chloride A

Ethyl chloride B

Methylene chloride B

Methyl chloride B

Cyclohexanol A

Chlorobenzene A

Propyl chloride A

Vinyl chloride B

Liquid fuels A

Cleaning compounds A

Cresol A

Crotonaldehyde A

Dean A

Deodorizers A

Trace waste A

Industrial waste B

Disinfectants A

Detergents B

Dibromoethane A

Dichlorodifluoromethane A

Dichloroethane A

Dichloroethylene A

Dichloromonofluoromethane B

Dichloronitroethane A

Dichloropropane A

Dichlorotetrafluoroethane A

Ethylene dichloride A

Diethylketone A

Dimethylaniline A

Dioxane A

Dipropylketone A

Carbon disulfide A

Ethane D

Ether B

Amyl ether A

Butyl ether A

Dichloro ethyl ether A

Ethyl ether B

Isopropyl ether A

Methyl ether B

Propyl ether A

Ethyl mercaptan D*

Ethylbenzene A

Ethylene chlorohydrin A

Eucalyptol A

Phenol A

Fluorotrichloromethane B

Ethyl formate B

Methyl formate B

Phosgene B

Ripening fruit A

Gangrene A

Gasoline A

Burnt fat A

Lubricating greases and oils A

Heptane A

Hexane A

Heptylene A

Hydrogen D

Incense A

Indole A

Isoforone A

Soaps A

Sour milk A

Calcined materials A

Menthol A

Mercaptans A

Methane D

Methyl butyl ketone A

Methyl ethyl ketone A

Methyl isobutyl ketone A

Methyl mercaptan A

Methyl cellosolve A

Methylcyclohexane A

Methylcyclohexanol A

Methylcyclohexanone A

Methylchloroform B

Mold B

Monochlorobenzene A

Monofluorotrichloromethane A

Styrene monomer A

Carbon monoxide D

Coal tar naphtha A

Petroleum naphtha A

Naphthalene A

Naphthalene A

Nicotine A

Nitro benzenes A

Nitroethane C

Nitroglycerin A

Nitromethane C

Nitropropane A

Nonano A

Octalene A

Octane A

Odorizers A

Garlic odor A

Animal odor B

Smell of dead animals A

Roasted meat odor A

Onion odor A

Sour cabbage odor A

Smell of spoiled food. A

Smell of burnt food A

Candy smell A

Rubber odor A

Smoke odor A

Cigarette smoke odor A

Popcorn odor A

Plastic odor A

Cheese odor A

Sweat odor A

Animal odor B

Body odors A

Bird odors A

Bathroom odors A

Butcher’s shop odors B

Citrus and other fruit odors A

Cooking odors A

Cooking odors A

Combustion odors B

Drainage odors A

Embanking odors A

Hospital odors A

Laboratory odors B

Liquor odors A

Makeup odors A

Pet odors A

Odor of deteriorated paper A

Fish odors A

Paint odors A

Odors from cleaning products A

Medicinal odors A

Persistent odors A

Musty odors A

Ethylene oxide B

Mesityl oxide A

Ozone A

Paradichlorobenzene A

Adhesives A

Pentane B

Perchloroethylene A

Perfumes and cosmetics A

Pyridine A

Pollen B

Waste products B

Prod. in decomposition A

Prod. for embalming A

C-radiation products

Propane C

Propyl mercaptan A

Putrescine A

Kerosin A

Organic chemicals A

Resins A

Burnt blood A

Ethyl silicate A

Smog A

B* bleaching solutions

Solvents B

Dimethyl sulfate A

Putrefying substances B

Tetrachloroethane A

Tetrachloroethylene A

Carbon tetrachloride A

Toluene A

Tolidine A

Trichloroethane A

Trichloroethylene A

Sulfur trioxide B*

Turpetin A

Urea A

Asphalt vapors A

Varnish vapors A

Fuel vapors C

Diesel vapors A

Vinegar B

Xylene A

Iodine A

Iodoform A

Hydrogen iodide B

More information on activated carbon for gas and air treatment:

Reactivation of granular activated carbon

Structure-modified activated carbon

What is the iodine number of activated carbon?