Description

PRECHARGED TANKS FOR HYDROPNEUMATIC SYSTEMS

Code |

Tank volume |

Tank system |

Maximum operating pressure (psi) |

Connection diameter (inches) |

NPT thread (male / female) |

Dimension diameter |

Maximum working temperature |

ALTAPRO X20 |

20 gallons |

diaphragm |

100 psi |

1″ |

female |

15.4″ |

49°C (liquid) and 52°C (ambient) |

ALTAPRO X26 |

26 gallons |

diaphragm |

100 psi |

1″ |

female |

15.4″ |

49°C (liquid) and 52°C (ambient) |

ALTAPRO X45 |

45 gallons |

diaphragm |

100 psi |

1.25″ |

female |

22″ |

49°C (liquid) and 52°C (ambient) |

ALTAPRO X65 |

65 gallons |

diaphragm |

100 psi |

1.25″ |

female |

22″ |

49°C (liquid) and 52°C (ambient) |

ALTAPRO X86 |

86 gallons |

diaphragm |

100 psi |

1.25″ |

female |

26″ |

49°C (liquid) and 52°C (ambient) |

ALTAPRO X119 |

119 gallons |

diaphragm |

100 psi |

1.25″ |

female |

26″ |

49°C (liquid) and 52°C (ambient) |

Applications:

- Domestic and commercial hydropneumatic systems.

- Ideal for coastal areas.

- Water purification systems.

Increased resistance against:

- Outdoor applications Solar and ultraviolet (U.V.) exposure

- Saline climate and humidity

- Acid rain

- Corrosion.

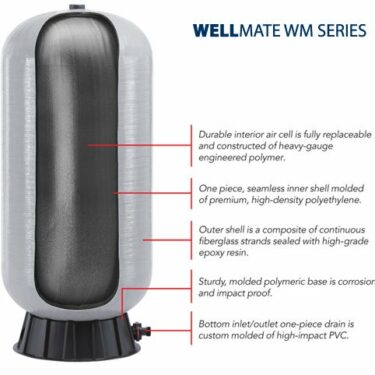

CONSTRUCTION FEATURES

Carbon steel outer casing and high quality welding process.

Parabolic diaphragm design, less fatigue, more durability.

It has a 304 stainless steel elbow, polypropylene inner cover and diaphragm molded in rubber and butyl so that water never comes in contact with the parts subject to corrosion.

Highly resistant plastic base designed to withstand high impact, according to ASTM D2794. Preload valve of metal construction.

OPERATING CHARACTERISTICS

- Maximum working pressure: 100 psi

- Working temperature: 49°C.

- Maximum ambient temperature: 52 °C

- Factory preload pressure : 38 psi.

Designed to withstand outdoor applications and where moisture can penetrate standard paint coatings applied over conventional steel tanks and cause corrosion. Coated with an ULTRA UV automotive grade zinc powder coat “sacrificial” paint, highly resistant to corrosion, which provides a self-protection backing. If the coating is damaged, the zinc prevents the steel from corroding. They resist ultraviolet (UV) rays from sunlight that fade the original color of the paint used on conventional steel tanks and also crack and chip tanks constructed of fiber. Tested for salt solution exposure in accordance with ASTM B117-73 for twice as long as standard tanks.