Description

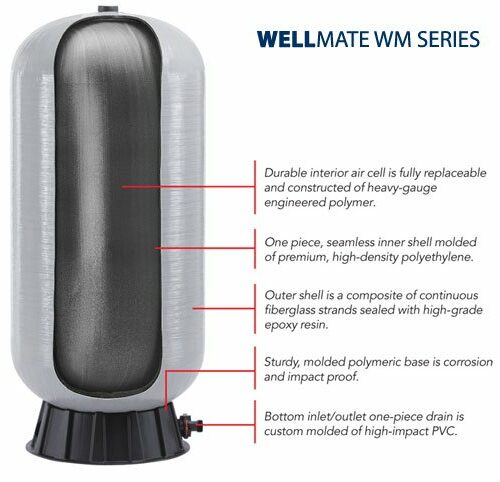

Wellmate pressure tank in fiberglass

The construction of a Wellmate fiberglass hydropneumatic tank’s greatest advantage is its resistance to corrosion. It is manufactured in one piece, seamless inner body molded from premium high density polyethylene.

Heavy-duty air blow molded inner membrane is fully replaceable and constructed of heavy gauge engineered polymer bottom entry/plug assembly is custom routed from high impact PVC.

Advantages of the Wellmate pressure tank in fiberglass

- Molded polymeric base with corrosion and impact resistance test.

- The outer body is a continuous filament fiberglass composite sealed with high quality epoxy resin.

- Replaceable air membrane.

- NSF Approval: The entire range of WellMate residential tanks are NSF/ANSI-61 certified for human use.

- Light weight – minimizes the cost of moving and loading maneuvers, without the need for heavy equipment.

The WM-Series offers features and benefits that steel tanks simply cannot match. From their corrosion resistant composite construction, light weight, easy maintenance and less costly installation, WM-Series pressure tanks are the preferred choice of professionals.

Features and Benefits

- Replaceable inner tube ensures ease of field service.

- Extended labor warranty option is available to owners.

- It does not rust in corrosive environments, particularly important in coastal regions.

- Faster and less expensive to install, they usually require only one person and fewer man-hours.

- Wider pressure differential adjustment provides greater flexibility.

Applications

Residential: residential houses and subdivisions.

Light commercial: in wet warehouses, high corrosion production lines and beach hotels.

Pressure increase: From closed hastening systems.

Models

| Models | Capacity | Maximum operating pressure | Drawdown | Diameter | Total height | Height* entrance/exit to the floor | Connections | Weight armed*. |

| gal / liters | psi / kPa / Bar | 30/50 Setting** | inches / cm | inches / cm | inches / cm | lb / kg | ||

| gal / liter | ||||||||

| WM-4 / WM0060 | 14.5 / 55 | 125 / 862 / 8.6 | 4.4 / 16.5 | 16 / 41 | 26 / 66 | 1 3/4 / 4.4 | 1″ male NPT | 14.5 / 6.6 |

| WM-6 / WM0075 | 19.8 / 75 | 125 / 862 / 8.6 | 5.9 / 22.5 | 16 / 41 | 32 / 81 | 1 3/4 / 4.4 | 1″ male NPT | 17.75 / 8.1 |

| WM-9 / WM0120 | 29.5 / 112 | 125 / 862 / 8.6 | 8.9 / 33.5 | 16 / 41 | 44 / 112 | 1 3/4 / 4.4 | 1″ male NPT | 24.75 /11.2 |

| WM-12 / WM0150 | 40.3 / 153 | 125 / 862 / 8.6 | 12.1 / 45.8 | 16 / 41 | 57 / 145 | 1 3/4 / 4.4 | 1″ male NPT | 30 /13.6 |

| WM-14WB / WM0180 | 47.1 / 178 | 125 / 862 / 8.6 | 14.1 / 53.5 | 21 / 53 | 41 1/4 / 105 | 2 1/4 / 5.7 | 1 1/4″ male NPT | 43 / 19.5 |

| WM-20WB / WM0235 | 60.0 / 227 | 125 / 862 / 8.6 | 18.0 / 68.1 | 24 / 61 | 41 1/2 / 105 | 2 1/4 / 5.7 | 1 1/4″ male NPT | 50 /22.7 |

| WM-25WB / WM0330 | 86.7 / 328 | 125 / 862 / 8.6 | 26.0 / 98.5 | 24 / 61 | 55 1/4 / 140 | 2 1/4 / 5.7 | 1 1/4″ male NPT | 72.75 / 33.0 |

| WM-35WB / WM0450 | 119.7 / 453 | 125 / 862 / 8.6 | 35.9 / 135.9 | 24 / 61 | 74 1/4 / 189 | 2 1/4 / 5.7 | 1 1/4″ male NPT | 95 / 43.1 |

Note: maximum external operating temperature of 120°F (49°C). Maximum internal operating temperature (38 ° C) 100 ° F. Minimum operating temperature (4 ° C) 40 ° F.

* Diameter, height and weight may vary slightly without prior notice.

** In accordance with current industry standards, the downside factors are based on Boyle’s law. Actual yields will vary depending on system variables, including the accuracy and performance of the pressure switch and a pressure gauge and the operating temperature of the system.

Other topics of interest: