What is a water disc filter?

Like any filter, it is an equipment whose objective is to retain suspended solids. It was born as a proposal to filter irrigation water, and little by little it found applications in all areas that use water.

It can be said that it started from basket-type filters, in which the filtering medium is a metal mesh. In the process of innovation, this medium resulted in independent plastic discs that are applied one on top of the other.

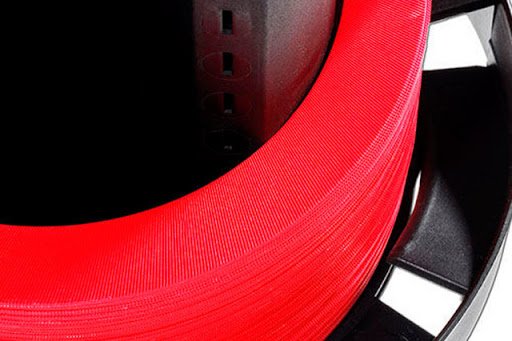

Fig. 1

How does a disc filter work?

The discs are ring-shaped. When stacked, they leave a central gap or channel. Each disc has grooves that are more open on the outer perimeter, and narrower on the inner perimeter. The efficiency in the filtration process is not only in the opening of these grooves, but in their geometry, angulation, intersections, length and quantity. The water flows from the outside into the central channel. The solids remain in the channels: the largest remain on the outside and the smallest reach the innermost part. This minimizes how often the discs will need to be cleaned. From the above, it follows that it is a “depth filter”.

Fig. 2

Fig. 3

How are the discs that make up the filter element of this equipment classified?

The discs are manufactured in different colors, and each color corresponds to a different opening or degree of filtration (Figure 1). Discs are produced with nominal apertures that are between 5 and 400 microns. The most widely used nominal opening has been 130 microns, which is usually adequate for irrigation or for surface water filtration.

What connection diameters does a disc filter have?

Disc filters, depending on their size, have connections between 3/4 “and 2”. However, groups of filters are formed connected to a manifold whose diameter can be between 6 ″ to 12 ″ inches (Figure 4).

Fig. 4

How are disc filters cleaned?

They can be cleaned manually or automatically. Manual cleaning requires one person to disassemble and perform the work. It is suitable for small systems, in which the concentration of solids to be retained is low, and in which forgetting this activity is not the cause of a serious problem.

Automatic cleaning consists of a backwash that is carried out over a period of time, or when the pressure drop in the filtration system reaches a certain level. In the backwash process, the flow is directed in the opposite direction to that of filtration, and the discs decompress. In this way, a good degree of cleaning is achieved.

In certain cases, a pump that generates sufficient flow may be required to achieve adequate backwash. There is also the possibility of backwashing with air assistance, when it is important to minimize water consumption.

Disc filters can retain various types of sediment. The least deformable and that do not agglutinate each other, as is the case of the sandy ones, constitute the simplest cases. While the solids to be retained are more deformable, the filter clogs more quickly, and cleaning is required more frequently.

What are the advantages of using water disc filters?

An advantage of this technology is that they use less water than conventional deep-bed filters, so that in the medium or long term, the economic convenience in saving water and in the time required for backwashing is greater. This and lower energy consumption are the main contributions of these teams.

Most common applications for water filtration with disc filters:

- Filtration for drip irrigation effluents.

- Surface water irrigation water filtration.

- Hydroponics systems.

- Industrial filtration.

- Filtration in water treatment plants.

- Pre-treatment of water softening or reverse osmosis systems.

- Water recirculation.

- Cooling towers (part of the filtering system).

- Replacement of sand, anthracite or zeolite filters in water treatment.

Comparte:

Necesitas más información, escríbenos.

Algunos productos que te pueden interesar

-

89 Canature Hydrotech control valve

Add to quote -

Elkay EZH2O DSSBF8S Elkay EZH2O DSSBF8S Pedestal Cold Water Dispenser with Bottle Filler

Add to quote -

Canature Hydrotech 105 Control Valve

Add to quote -

RoClean L211 cleaning of membranes with organic matter fouling

Add to quote -

Canature Hydrotech 765 Control Valve

Add to quote -

RoQuest 3000 Organic Liquid Coagulant from Avista

Add to quote -

AA-3 Activated carbon to reduce color and flavor in tequila and other distilled spirits

Add to quote -

Canature Hydrotech 565 control valve

Add to quote