Disc or ring filters for industrial and self-cleaning applications (i.e. automatic backwashing)

Some of the aspects described in this document are common to the different brands of automatic disc filters, and others are specific to Azud.

Disc or ring filters are currently a very generic equipment but it is one of the most important innovations in the history of water filtration. It is produced by various manufacturers.

In terms of applications, disc filters can be classified as follows:

- Minors (domestic, commercial…)

- Industrial

The ways to clean them once they have become clogged (i.e., once the retained solids have blocked an important part of the free area for flow), are classified as follow:

- Manual cleaning

- Self cleaning

In this article we will describe only disc filters for industrial and self-cleaning applications.

Liquid filtered with this type of filters

They are designed to filter water: from salt-free water to seawater. The materials of construction make them suitable for treating various liquids. However, the fact that these filters are capable of treating high flow rates, they find most applications in water treatment.

Grade of filtration (nominal diameter of solids retained by disc filters)

It is usually between 5 and 400 microns.

Elements that compose a disc filtration system.

Unlike other types of industrial filters, disc filters are not manufactured in different dimensions.

Each manufacturer designs a basic filter element, with unique dimensions, and makes up a complete filtration system, with the number of elements necessary to treat the entire flow that needs to be filtered.

Disc filter systems for different capacities

As mentioned above, a complete disc filtration system is made up of the number of filter elements necessary to treat the entire flow to be treated. This means that the capacity of this equipment is increased modularly. The following pictures show arrangements with a different number of filtering elements.

The images above show that several filter elements are connected to a common manifold.

Discs

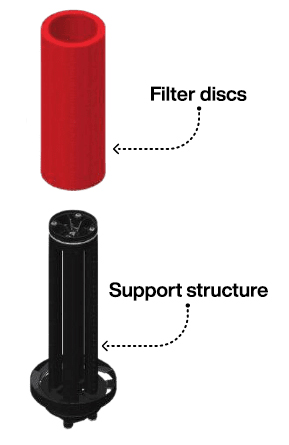

These filters use discs that are stacked and centered around a support structure, so that they form a cylinder with a hollow inner shaft.

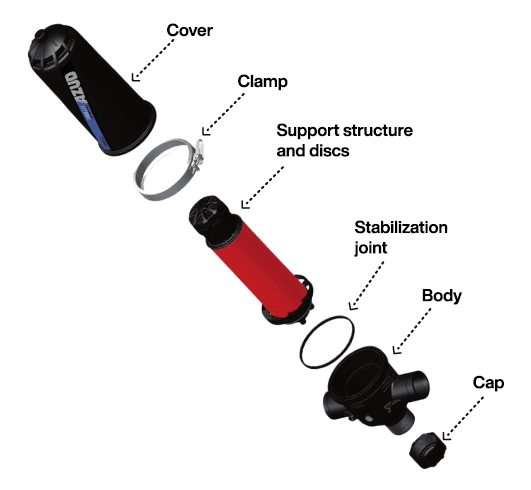

The following image shows the parts of an Azud Helix filter element.

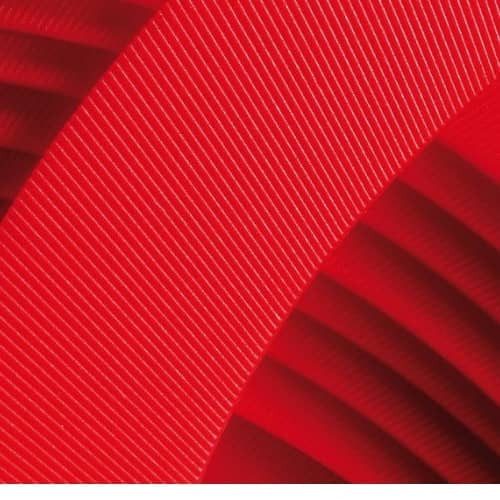

Disc grooves

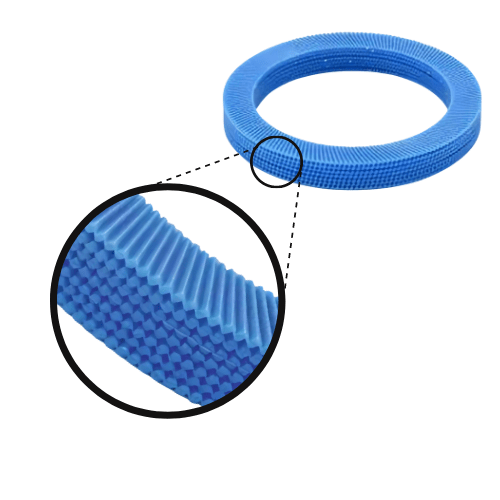

The discs have engraved grooves. Some discs have the grooves engraved on only one of their flat sides. Others have them engraved on both sides. Each manufacturer often design the grooves on their discs to differentiate its brand.

Support structure of the filter discs

The following images show the support structure, on which the discs are placed Azud manufactures this structure which is composed of four columns. Each column has a series of nozzles through which the backwash water for the automatic disc filters is injected.

Cover or casing

The cylinder formed by the discs placed on the support structure has a cover that can be put on and removed without the use of tools. The housing is fixed to the support structure by means of a clamp that is attached and removed by hand.

The support structure has the connections through which the water enters and exits.

The following picture shows a disc filter consisting of three filter elements. The element on the left has only the support structure (without discs). The center element already has the discs installed. And the element on the right already has the cover or housing installed:

The following image shows two filter elements: the one on the left has the housing that is used to operate. The one on the left has a transparent (acrylic) housing, for demonstration or didactic purposes. The latter does not have adequate mechanical strength for long-term operation.

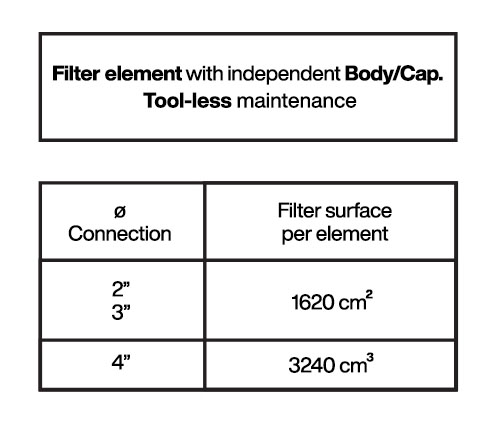

Filter area of each element

The filtering area of each element is the outer surface of the cylinder formed by the discs. The outer diameter of the discs is about 12.9 cm and the length of the cylinder formed by these discs is 40 cm. Therefore, the filtering area of each element is about 1620 cm2.

The volume of the empty casing is 9 liters.

The volume of the housing with the support and the disks inside it is 6.5 liters.

Applications of automatic disc filters:

Automatic disc filters can be used for any application as a replacement for the deep bed or multimedia filter.

Some current applications of automatic disc filters are:

- Filtration of municipal wastewater.

- Treatment of water used for industrial waste disposal.

- Food manufacturing processes.

- Textile production.

- Filtered water for irrigation.

- Cooling towers.

- Cooling towers and many other processing industries.

The disc filter provides the same area as the screen filter with the additional dimension of depth filtering.

Recent additions of hard plastic, stainless steel components and a revolutionary automatic backwash process increase the versatility of this technology.

Filters are offered in a range of dividers with filtration ratings from 5 to 400 microns.

Video of the self-cleaning or backwashing process of disc filters.

Do you require more information about automatic disc filters?

Receive advice from Carbotecnia and Azud México

We work with AZUD in every industrial filtration project.

We design, recommend and install industrial water treatment plants.

Fill out the form below to receive advice: