Deep bed filtration.

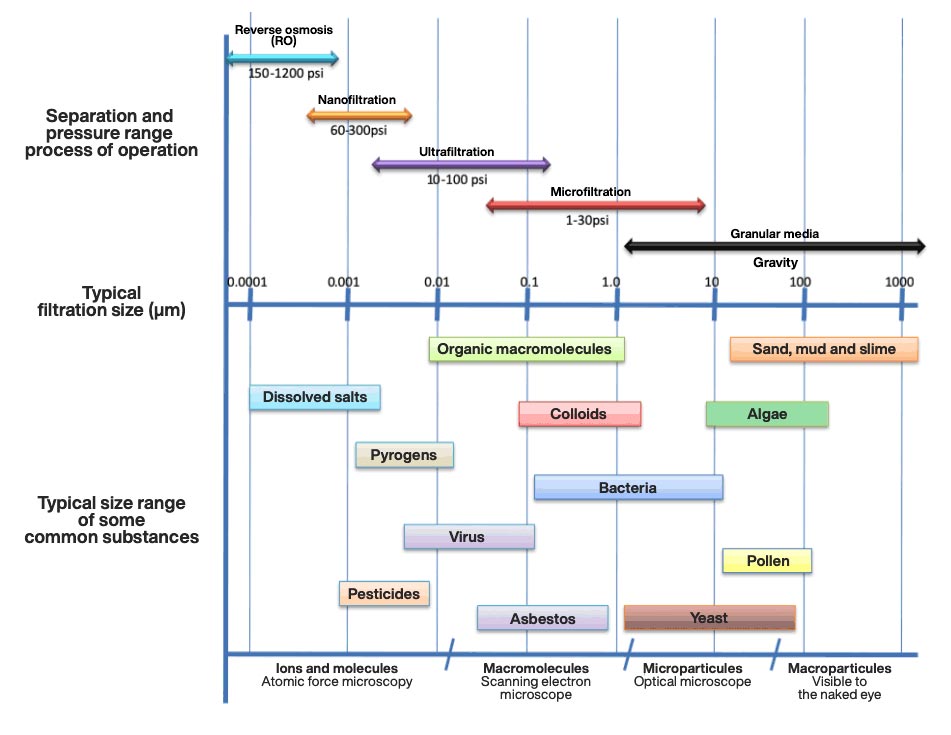

In water treatment, filtration is a process to decrease the concentration of suspended solids (particles). There are several types of filters and each of them has its application, which depends on the size of particles to be retained. In Figure 1 shows the different types of filtrations and the typical size of particles they retain.

Figure 1. Filtration processes and size ranges (Weiner, 2012)

Granular media filters are “deep”. This means that they perform their function along a certain depth of the media. Usually, these filters are designed with a bed height of between 15 and 30 inches. The particles retained may be smaller than the pore spaces in the bed.

These filters can operate under gravity or pressure. The former is similar to a pool with a filter bed.

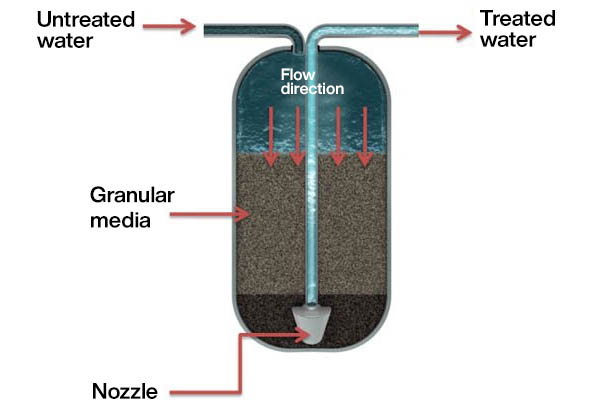

The pressure filters are usually vertical cylindrical, with formed covers (torispherical, elliptical or other). They are manufactured in carbon or stainless steel, and in inner polyethylene and outer fiberglass. The water enters the filter from the top and flows through the bed in a downward direction. The water is collected at the bottom of the bed (Figure 2), by means of diffusers. After a period of service the filter should be backwashed to expel retained solids, and to expand the bed to prevent cementation, cracking and subsequent channeling of the water that is filtered. Backwashing consists of making water flow upwards.

Figure 2. Filter in operation

What are granular media?

The most common granular media used in deep bed filters are silica sand, anthracite and garnet (garnet ; the latter is also known as high density sand. The norm B100 of the American Water Works Association (AWWA) provides the sampling, evaluation, installation, packaging, and property requirements for these materials.

The particle size of the granular filter media must be large enough to allow a significant percentage of the suspended solids to be retained to penetrate two to four inches deep into the bed. Rough and angular media form larger voids that allow more fine particles to pass through than a round granular media of the same size.

The size of the granular media is specified in terms of effective particle size and coefficient of uniformity. The effective particle size is a mesh opening that will allow 10% by weight of the particles in the granular medium to pass through. The coefficient of uniformity is the result of dividing the opening of a mesh that would allow 60% by weight of the particles in the granular medium t pass by the effective particle size. The effective particle size is usually reported in millimeters, and the coefficient of uniformity is dimensionless.

The closer the uniformity coefficient is to the unit, the greater the uniformity in the size of the particles in the medium. The ideal size for a granular media depends on the characteristics of the suspended solids as well as the quality requirements of the filter effluent.

In order to increase the operating time of a filter bed formed by a granular medium, two or three granular media can be installed to form it. In the upper part, the granular medium of larger particles and lower particle density is placed. In the lower part is placed this one of smaller particles and higher particle density. These media are chosen so that, when backwashing both or all three expand, and when backwashing is completed, they return to their original position. In this way, the upper granular medium retains the larger suspended particles carried by the water, and the lower granular medium retains the smaller particles. This is the reason why it takes longer for the multi-bed to become clogged and require backwashing.

Tables 1, 2 & 3 list the materials used for multi-bed filtration, recommended by different authors.

Table 1. Material specifications for multi-bed filters: AWWA. (2016). ANSI/AWWA B100-16 Granular Filter Material. American Water Works Association.

|

Granular medium

|

Particle size

|

Uniformity Coefficient

|

Specific gravity

|

Acid Solubility

|

|---|---|---|---|---|

|

Anthracite

|

0.6 – 1.6 mm

|

|

>1.4

|

|

|

Silica sand

|

0.35 – 0.65 mm

|

|

>2.5

|

|

|

Garnet

|

0.18 – 0.60 mm

|

|

>3.8

|

|

Table 2. Material specifications for multi-bed filters: DeZuane, J. (1997). Handbook of Drinking Water Quality. John Wiley & Sons, Inc.

|

Granular medium

|

Particle size

|

Uniformity Coefficient

|

Specific gravity

|

Acid Solubility

|

|---|---|---|---|---|

|

Anthracite

|

0.80 – 0.85 mm

|

|

1.5-1.65

|

|

|

Silica sand

|

0.52 – 0.55 mm

|

|

2.65

|

|

|

Garnet

|

No report

|

No report

|

No report

|

No report

|

Table 3. Material specifications for multi-bed filters: AWWA. (1999). Water Quality & Treatment a Handbook of Community Water Supplies. McGraw-Hill.

|

Granular medium

|

Particle size

|

Uniformity Coefficient

|

Specific gravity

|

Acid Solubility

|

|---|---|---|---|---|

|

Anthracite

|

0.9 – 1.1 mm

|

No report

|

1.45-1.73

|

|

|

Silica sand

|

0.45 – 0.55 mm

|

No report

|

2.65

|

|

|

Garnet

|

0.2 – 0.3 mm

|

No report

|

3.6-4.2

|

|

Granular support media and water distribution systems.

The function of the diffusers in a filter is to support the filter media, collect and direct the water out of the filter, as well as distribute the water (and air, in rare cases) for backwashing. The appeared on the market in recent years, and are described below.

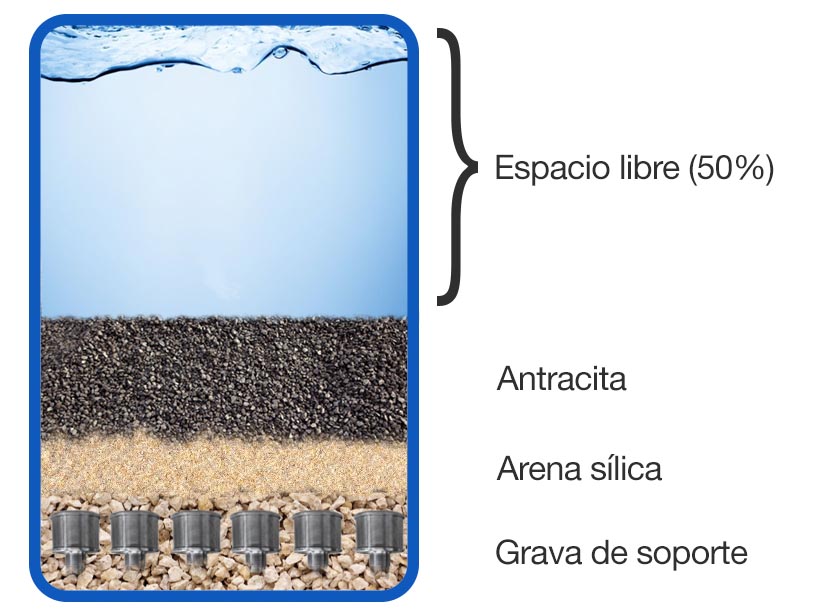

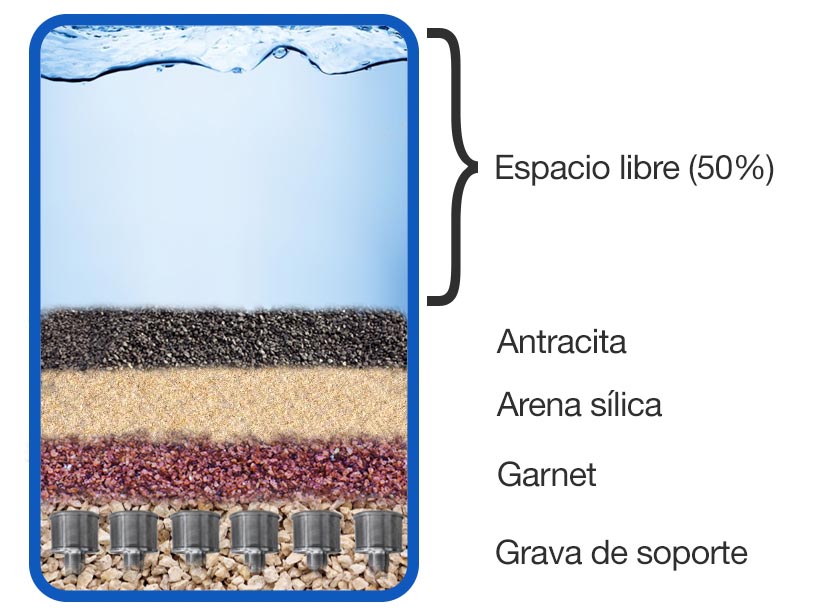

Previously, water distribution systems consisted of an arrangement of pipes with drill holes. These holes used to have a diameter of ¼” and ½”. The perforated pipe was immersed in a layer of gravel whose smaller particles had to be at least twice the size of the perforations. A layer of gravel was placed on top of the perforated pipe, with smaller and smaller particles up to the layer that held the granular filter medium (Figure 3). The guide for selecting size and depth of the gravel support layers for a granular media filter can be found in Appendix D of the AWWA B100-16 standard.

Dual bed deep bed filter

Multimedia Deep Bed Water Filter

Figures 3. Granular media distribution system for a Dual bed (Sand and Anthracite) or Multimedia bed (Garnet, Silica Sand and Anthracite) both with Silica Gravel support bed.

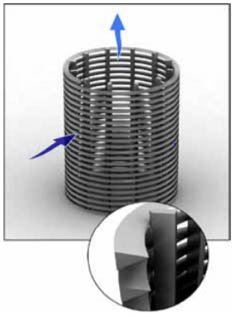

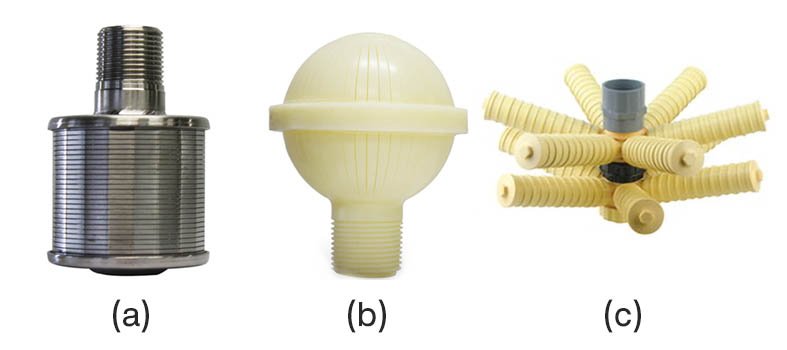

Modern diffusers are micro-grooved systems with a special design (such as the Johnson type slot, Figure 4) that prevent the passage of filter material into the diffuser without the use of gravel. These diffusers can have different shapes, as shown in Figure 5.

Figure 4. Johnson-type element design.

To achieve an even distribution of the backwash flow, the following is recommended:

- The opening of the holes should be small enough to have a controlled pressure drop. The pressure drop at the distributors during backwash varies from 0.1 to 3 m water column. This depends on the design of the valves and the speed of the backwash.

- The flow velocity in the distribution system pipe should be uniform throughout the entire cross-sectional area of the filter.

Figure 5. (a) Johnson stainless steel nozzle, (b) Johnson type ABS hydrosphere, (c) Bajonet Pentair diffuser

Backwash.

Backwashing is an indispensable part of the operation of all granular media filters, consisting of fluidisation of the bed (the percentage at which the bed must be expanded depends on each granular medium). Incorrect execution or omission of backwashing is the most frequent cause of problems in granular media filters. Problems that can occur from improper backwashing are as follows:

- Sludge formation on the surface causing a reduction in the area available for filtration. This causes an increase in hydraulic load (surface velocity) and pressure drop.

- Leakage of particles carried by the effluent.

- By not backwashing the bed properly (i.e., achieving bed expansion) often enough, the granules stick together. When this happens, the bed is said to have petrified. A petrified bed eventually fractures, causing the flow to be channeled (i.e., to flow through the cracks), and not to leak.

More information about backwashing here

Sources:

- (2016). ANSI/AWWA B100-16 Granular Filter Material. American Water Works Association.

- (1999). Water Quality &Treatment a Handbook of Community Water Supplies. McGraw-Hill.

- (2011). Operational control of coagulation and filtration processes. American Water Works Association.

Comparte:

Necesitas más información, escríbenos.

Algunos productos que te pueden interesar

More articles: Sediment filters What are they and how do they work?