How can you save up to 40% on the cost of replacing activated carbon?

A practice that few people talk about in Mexico, which can save up to 40% of the cost per kilo of coal and is also environmentally friendly, is: coal reactivation. The main benefits of depleted coal reactivation are:

The price per kilogram of reactivated coal is approximately half the cost of virgin coal.

Performance.

The spent coal practically recovers its initial capacity after reactivation.

Ecology.

Prevents spent coal residues from going to inappropriate places, which can cause damage to the environment and health.

Security.

By reactivating spent coal you virtually eliminate the costs and liability associated with its disposal.

What other environmental benefits do we generate with the reactivation of a coal?

➩ Polluting waste is minimized and the amount of CO2 associated with the production, supply and use of virgin activated carbon is reduced .

➩ Helps prevent GAC from taking up space in landfills.

➩ Prevents leachate or pollutant emissions from spent GAC.

Would you like to receive these economic and ecological benefits?

Send us your data:

We will tell you how you can confirm if your coal is viable for reactivation:

How is a coal reactivated?

It’s possible to reactivate spent granular activated carbon by various methods, thermal activation is the most common (exposed to 800 °C on a rotary furnace in an atmosphere saturated with water vapor.)

The charcoal obtained usually recovers its full original capacity. With reactivation (recycling), the need to dispose of the spent carbon (as industrial waste) is avoided and savings of up to 50% can be achieved in the replacement of the activated carbon – reactivation.

After the adsorption capacity of an activated carbon has been spent it is fully recyclable, the adsorbed organic compounds are destroyed and the reactivated carbon can be safely and cost-effectively recycled for continued use.

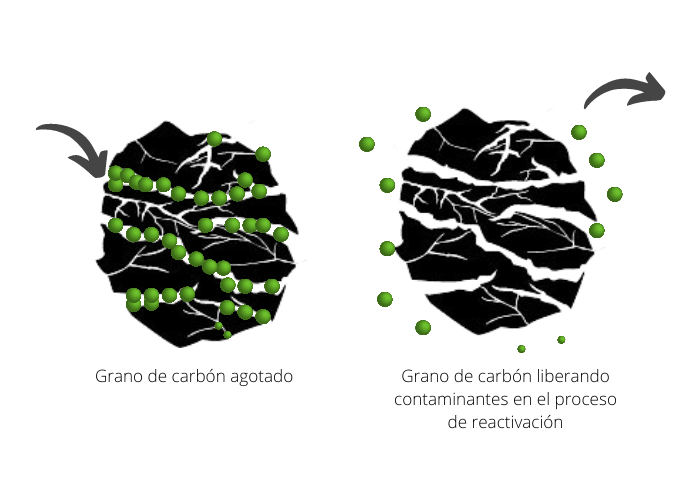

The following image illustrates step 2 of the reactivation process:

The reactivation process involves the following steps:

➩ We have been reactivating and manufacturing coconut shell charcoal for more than 25 years.

We have the permits before SEMADES for its reactivation, we deliver all the documents involved in the process, in addition to a quality certificate.

We also offer collection, collection and disposal of spent activated carbons.

If you use charcoal for any of these applications: it can be reactivated.

Water purification.

Activated carbon from water purification and industrial water treatment plants.

Treatment of beverages

Activated carbon is used as a purifier to reduce certain odor, flavor and color molecules in Tequila, Rum, Mezcal and other beverages.

Purification of organic gases

Granular and pellet activated carbons are used to reduce industrial and commercial gas pollutants.

Manufacturing processes.

Activated carbon is classified as “special handling waste” and is used in a wide variety of industrial processes.

Would you like to know more about the reactivation service? Contact us:

We will tell you how you can confirm if your coal is viable for reactivation: