Description

Filter tanks Commercial and industrial composite

Code |

Description |

|---|---|

P_046084 |

Tank 18″ x 65″ Composite 4″ T |

P_046085 |

Tank 21″ x 62″ Composite 4″ T |

P_046086 |

Tank 24″ x 65″ Composite 4″ T |

P_046087 |

Tank 24″ x 72″ Composite 4″ T |

P_046088 |

Tank 24″ x 72″ Composite TF 6″, BF, Tripod Base |

P_046089 |

24″ x 72″ Composite TB 4″ Tank |

P_046090 |

30″ x 72″ Composite TB 4″ Tank, Tripod Base |

P_046091 |

Tank 30″ x 72″ Composite 4″ T |

P_046092 |

30″ x 72″ Composite TF 6″ Tank |

P_046093 |

30″ x 72″ Composite TB 6″ Tank, Tripod Base |

P_046094 |

36″ x 72″ Composite TB 4″ Tank, Tripod Base |

P_046095 |

Tank 36″ x 72″ Composite 4″ T |

P_046096 |

36″ x 72″ Composite TF 6″ Tank |

P_046097 |

36″ x 72″ Composite TB 6″ Tank, Tripod Base |

P_046098 |

42″ x 72″ Composite TB 6″ Tank, Tripod Base |

P_046099 |

48″ x 72″ Composite TB 6″ Tank, Tripod Base |

P_046100 |

63″ x 67″ Composite TB 6″ Tank, Tripod Base |

P_046101 |

63″ x 86″ Composite TB 6″ Tank, Tripod Base |

Composite pressure vessels are used for large commercial and industrial applications.

Applications of Pentair Composite tanks:

- Water softeners

- Deep bed sediment filters (dual and multimedia)

- Demineralizers

- Industrial water filtration

- Water treatment plants

- Storage

Pressure vessels Pentair Water has been the industry benchmark for quality and performance for over 30 years.

Poly-crystal tanks are manufactured in one-piece, high-density polyethylene lining, highly resistant and leak-free, due to the engineering of the encapsulated polymer.

Composite pressure vessels feature a reinforced fiberglass construction offering excellent performance and durability.

Available in capacities up to 1600 gallons with a variety of different configurations. Pentair Water pressure filter tanks are designed to give you years of worry-free performance.

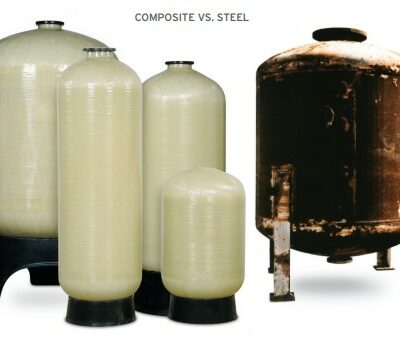

BENEFITS of Composite vs. Carbon Steel tanks

Steel tanks:

- Very heavy and unwieldy and therefore involves a higher installation cost.

- They corrode and rust over a short period of time.

- The interior has to be treated periodically.

- Paint and siding need to be renewed on a regular basis.

Composite structural tanks

- 60% lighter than steel and easier to handle, therefore, installation costs are lower.

- Corrosion resistant, both inside and outside.

- Low maintenance.

- Natural fiberglass exterior never fades or changes color; plus it has UV protection.

Design parameters – NSF

Safety factor: 4: 1 (minimum burst at 600 psi)

Cycle test: 100,000 cycles without leakage

Design parameters – ASME

Safety factor: Upper / lower flange 5: 1 (Minimum explosion at 750 psi)

Lateral flange 6: 1 (minimum explosion at 900 psi)

More information on the difference between Steel VS Pentair Composite tanks: https://www.carbotecnia.info/PDF/tanques/T.P.%20Composite%20vs%20Steel.pdf

Cycle test:

33,000 cycles without leakage (upper / lower flange)

100,000 cycles without leakage (side flange)