Description

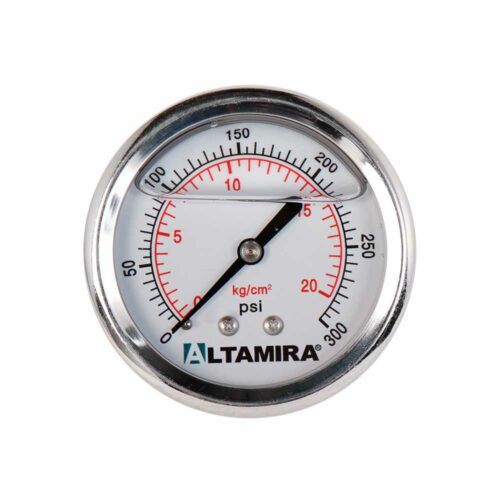

Glycerin pressure gauges from 100 to 300 PSI in stainless steel.

Altamira pressure gauges offer an easy-to-read dial, printed with UV-resistant ink, which ensures that the measurement is easy to read even after years of use, even when exposed to direct light.

Each pressure gauge is tested and inspected to ensure quality and resistance to the most demanding applications such as reverse osmosis systems, refineries, chemical processing and food processing plants.

Code |

Model |

Connection |

Description |

|---|---|---|---|

P_163091 |

MAN0-100G |

At the base |

Pressure gauge with ALTAMIRA glycerin. Stainless steel body. Cover page: 2.5-. 1/4- NPT. Scales in lb/plg2 (psi) and kg/cm² Maximum Pressure 100 psi |

P_163092 |

MAN0-200G |

At the base |

Pressure gauge with ALTAMIRA glycerin. Stainless steel body. Cover page: 2.5-. 1/4- NPT. Scales in lb/plg2 (psi) and kg/cm3 Maximum Pressure 200 psi |

P_163093 |

MAN0-100GBM |

Rear |

Pressure gauge with ALTAMIRA glycerin. Stainless steel body. Cover page: 2.5-. 1/4- NPT Scales in lb/plg2 (psi) and kg/cm² Maximum Pressure 100 psi |

P_163094 |

MAN0-200GBM |

Rear |

Pressure gauge with ALTAMIRA glycerin. Stainless steel body. Cover page: 2.5-. 1/4- NPT. Scales in lb/plg2 (psi) and kg/cm3 Maximum Pressure 200 psi |

P_163095 |

MAN0-300GBM |

Rear |

Pressure gauge with ALTAMIRA glycerin. Stainless steel body. Cover page: 2.5-. 1/4- NPT. Scales in lb/plg2 (psi) and kg/cm3 Maximum pressure 300 psi |

Standard features

- Easy to read cover.

- Resistant connections.

- Various receptacle materials.

Material

- Body: 304 stainless steel.

- Connection: Bronze

- Lens: Clear acrylic.

- Cover: Aluminum.

- Needle: Aluminum.

- Liquid: UV resistant glycerin.

Operating ranges

Pressure

- 0-100 PSI

- 0-200 PSI

- 0-300 PSI

Temperature

- -18oC (0oF) – 60oC (140oF)

What are pressure gauges?

A pressure gauge is a device that measures and displays the pressure of a fluid in a closed system. It is used in many industries, to show pumping pressure, in water treatment and irrigation among others, especially for hydraulic and pneumatic measurement. Pressure gauges measure the amount of force per unit area applied to an object by introducing air or liquid into a chamber with two hoses attached to it. The pressure gauge has two readings: one indicates the pressure inside the chamber (which glycerin gauges have better needle control) at a given moment and the other indicates the atmospheric pressure outside the chamber (which means that there would be no difference between these two readings if no fluid was circulating).

The pressure gauge is also used to measure pressure in different units depending on the sector. For example, automotive technicians use kilopascals (kPa), while aerospace technicians use pounds per square inch (PSI). Pressure gauges are used in many industries, such as automotive and aerospace.

How does a pressure gauge work?

The operation of a pressure gauge is based on the Bourdon tube principle. The Bourdon tube is a coiled tube, where one end is closed and the other end is connected to the fluid to which the pressure is to be measured. When the fluid enters the tube, it generates a force that causes the tube to uncoil. The degree of uncoiling of the tube is directly related to the fluid pressure.

Industrial pressure gauges usually have a graduated scale that measures pressure in units such as bar, pascal or psi (force per square inch), the latter being the most common. All pressure gauges have an element that changes some property when subjected to pressure.

Pressure gauges are used to set up and adjust fluid power machines. In hydraulic systems, pressure gauges ensure that there are no leaks or pressure changes, making fluid power systems more reliable and unpredictable.

What is the operating pressure of a pressure gauge?

In addition to measuring the amount of force per unit area, pressure gauges also indicate the direction of that pressure. The operating pressure of a pressure gauge can be used to calculate how much force to apply or where to apply it. Pressure gauges are commonly used in homes and businesses to monitor water flow in plumbing systems ranging from 0 to 100 PSI pressure; they are also essential tools for professionals working in the manufacturing, engineering and construction fields who need accurate measurements on equipment such as boilers that can range from 0-200 or 0-300 PSI.

There are pressure gauges for higher flow rates 0 to 1500, 3000 and 6000 PSI, you can see them in the following link High pressure glycerin pressure gauge 1500, 3000 and 6000 PSI Industrial use (carbotecnia.info)

Different types of pressure gauges

What are the different types of pressure gauges and what is the operating pressure of a pressure gauge?

There are four main types of pressure gauges:

- Glycerin manometer: this type of manometer uses glycerin as the fluid to measure air or gas pressures, which means that it is only accurate at higher temperatures (above freezing point).

- Bourdon tube – Invented by French physicist Louis Bourdon in 1845, this type of manometer uses a flexible tube that changes shape when exposed to an external force such as gas or liquid pressure at its ends. The resulting movement leads to an increase or decrease in its length, which directly correlates to the change in mass within its walls due to expansion or contraction from climatic conditions such as temperature variations; thus providing an accurate reading through mechanical action based on those factors alone without having any electronics involved at all! A good example would be the old home barometer: When the weather is going to be bad, you are very likely to see clouds forming before anything happens, because they are usually formed mainly by clouds.

Other types of pressure gauges:

- Instruments that measure pressure. Pressure gauges are used to measure the amount of force exerted on a surface or object. You may be familiar with some common types of pressure gauges, such as barometers and tire pressure gauges.

- Analog versus digital pressure gauges. Analog manometer: A mechanical manometer that measures atmospheric pressure using two columns of liquid separated by a flexible diaphragm, which deflects when atmospheric pressure increases and compresses when it decreases; it is commonly used to measure air flow in homes and factories, but can also be used for other purposes, such as measuring blood flow in arteries (arterial tonometry). Digital pressure gauge: A type of electronic instrument that uses an analog-to-digital converter (ADC) circuit to convert the output of a strain gauge into an electrical signal; usually found inside hydraulic systems to measure fluid level or flow rate changes caused by temperature fluctuations or other factors.

Conclusion

We hope this information has helped you understand the operation and uses of pressure gauges. If you would like to learn more about pressure gauges or other types of instruments used in industry, please contact us today.

Source:

https://como-funciona.co/un-manometro/

https://abaa.mx/blog/como-funciona-un-manometro-calibracion-manometro/