Description

Filters for cooling towers or refrigeration towers.

Cooling tower systems are used in municipal, residential, industrial and data processing centers (DPC) to dissipate the heat generated during their productive activity and guarantee the optimum process temperature.

These systems must cool large volumes of water and/or air, this water must contain particles or sediments that are deposited or accumulate on the various heat transfer surfaces of the circuit, which reduces the performance of the installation, increases the temperature of the water in the process and causes productivity losses and increased operating costs.

How do these solid particles reach the cooling system?

The incoming water source: contains suspended and dissolved solids in variable quantity and nature depending on their origin. It could also have undergone some pretreatment to improve the quality of the water entering the circuit.

Outdoor environment: particles that are suspended in the air, such as

dust, pollen, spores and microorganisms and enter the system through the environment where it is located.

Process water: due to wear of system components, dosing of inhibitors and biocides or other elements of the re-circulation system.

What sediments we are dealing with:

INLAYS

The loss of solubility of certain salts, mainly CaCO3, in contact with high temperatures, causes their precipitation on the heat transfer surfaces of the circuit, minimizing its energy efficiency.

SETTLEABLE SLUDGE

The accumulation of suspended particles in areas of low water velocity in the system generates obstructions, favors biological growth and increases the intensity and duration of maintenance shutdowns.

BIOLOGICAL PROLIFERATION

The development of algae, protozoa and bacteria generates biofilms (heat transfer 25 – 600 times lower than many metals), corrosion and in the case of Legionella Pneumphila poses a risk to human health.

CORROSION

Degradation of the system’s metal surfaces increases costs due to premature equipment replacement, unplanned production downtime and loss of heat transfer efficiency. Plastic disc filters avoid this problem so the filtration in the cooling system will last for many years.

Disc Filter for Cooling Towers

Advanced solution for optimum cooling efficiency

Filter characteristics:

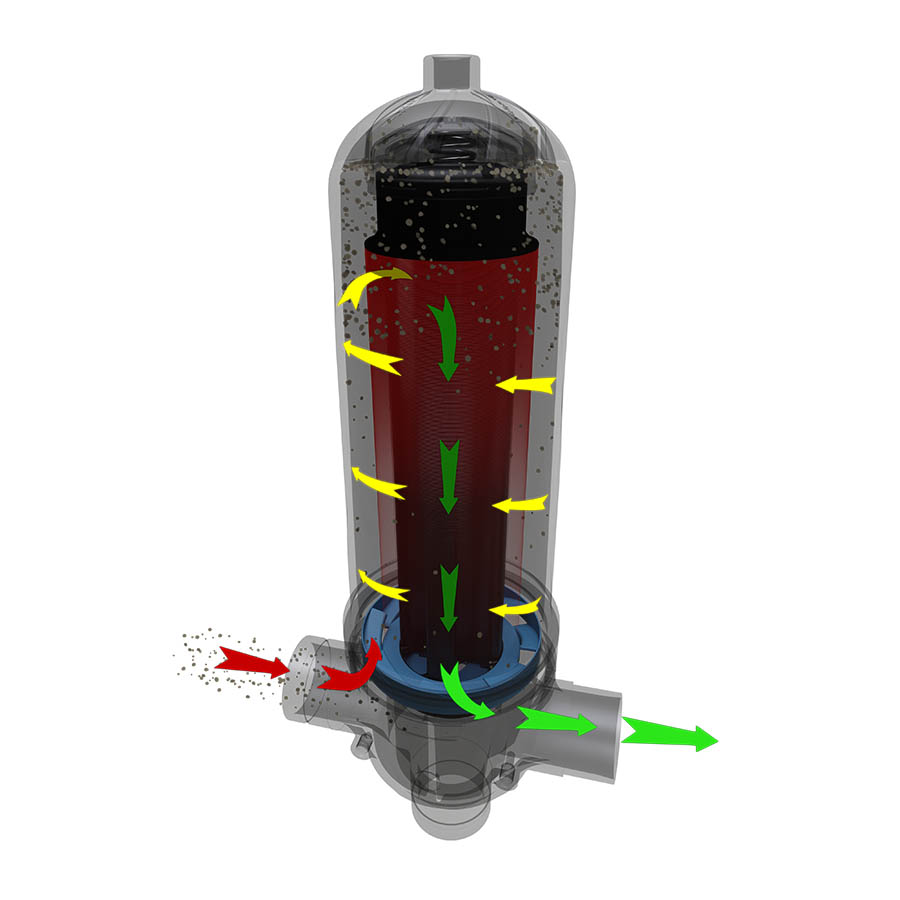

- Effective microfiltration: Disc filters retain small particles and solids that can reduce the efficiency of your cooling towers.

- Increased durability: Robust structure and high quality materials. Disc filters have a long service life, reducing maintenance and replacement costs.

- Ease of use: Disc filters are easy to install, use and maintain.

- Reduced water consumption: Increasing the efficiency of your cooling towers can reduce the amount of water needed, saving on operating costs.

Benefits of the cooling tower filter:

- High filtration performance: Disc filters will keep your cooling towers running efficiently and effectively.

- Savings: Operating, energy and maintenance costs are reduced due to the filter’s durability and efficiency.

- Environmentally friendly: By reducing the amount of water used, disc filters are a more sustainable and environmentally friendly option.

- Improved safety: Reduces the risk of proliferation of Legionella and other microorganisms.

Improve the performance of your cooling towers with our high efficiency disc filters today.

For more information or to place an order today, call us at the number provided. Experience the difference with our disc filters – Exceptional durability, performance and savings.

Transform your cooling process and make your contribution to a more sustainable future. Act today!

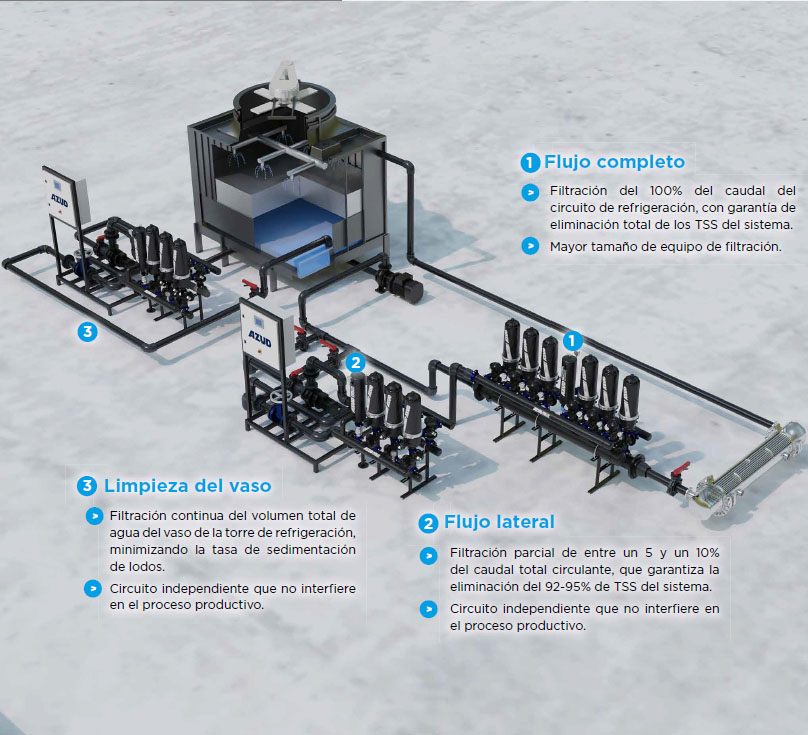

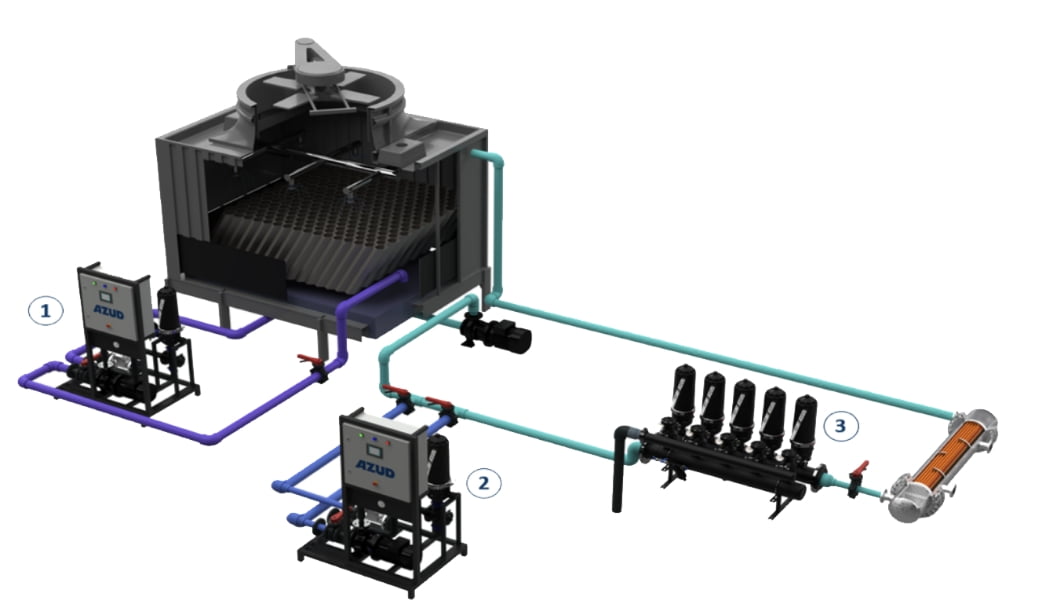

Cooling tower filtration scheme

Choice ① CLEANING THE VASE.

Recirculation filtration equivalent to the full volume of the system every 4-6 hours.

Ideal for implementations where the cooling circuit is inaccessible or hydraulic intervention is to be avoided.

Choice ② SIDE FLOW FILTRATION.

Filtration of 5-20% of the circulating flow.

Advisable in installations where the cooling tower is not intended to be modified.

Choice ③ TOTAL FLOW FILTRATION.

Filtration of 100% of the circulating flow.

This higher capacity filtration solution involves hydraulic interaction in the cooling circuit.

Benefits at specific points in the water filtration system

Nozzle protection

Spray nozzles are essential for various production processes. To maintain their efficiency and reduce maintenance costs, it is vital to protect them from erosion and clogging caused by particles in the feed water. Using a filtration system can improve nozzle life and maintain stable production.

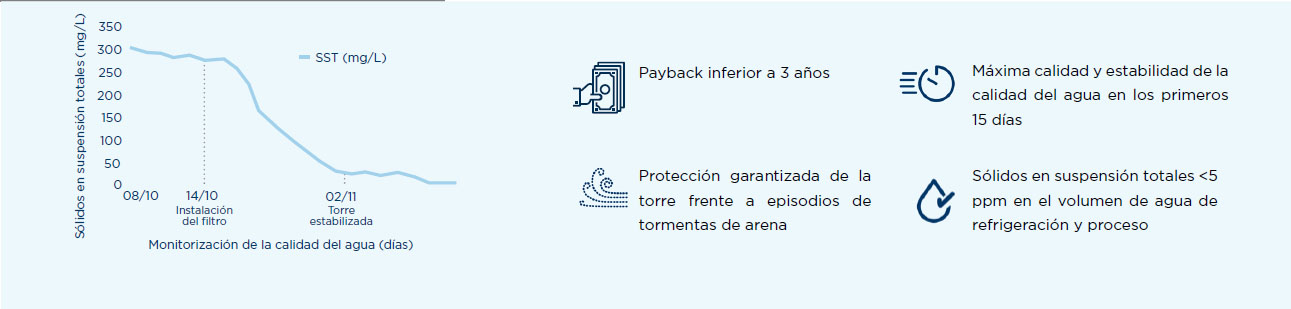

Side Stream in Cooling Towers

Cooling towers are more efficient when they are clean. Since they operate outdoors, they are vulnerable to the accumulation of dirt and debris. The solution is to use 25-100 micron filters to filter 5-15% of the sidestream. This will increase system efficiency and reduce both corrosion rates and maintenance costs.

Full current in cooling systems

Full stream filtration directly protects heat exchangers and coolers. This is done by installing a coarse filter at the pump discharge and finer filtration to protect other equipment. The available filters offer a wide range of filtration grades, providing complete solutions.

Heat exchanger protection

Heat exchangers are essential in manufacturing facilities and their efficiency is critical. By installing filtration upstream of the heat exchanger, suspended solids and debris are reduced, thus maintaining the heat exchanger and increasing its service life and productivity.

Loop protection on Condenser and Cooler

Condenser and cooler loop systems require filtration to remove large particles and prevent clogging, as well as small particles to prevent sedimentation. Continuous removal of suspended solids ensures long-term system efficiency.

Pump seal protection

The use of filtration can help protect pump seals and bearings by removing harmful particles, especially from the harsh exterior. This system can prevent costly damage and parts replacement.

Cooling Tower make-up water

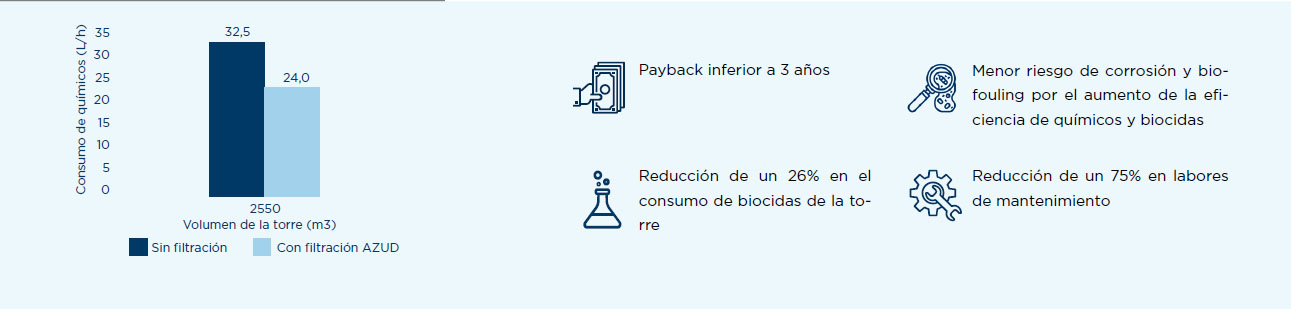

Make-up water is added to the cooling tower collection basin to replace water lost through evaporation and other processes. Using filtration in this process can improve water quality, reduce corrosion, and reduce the use of chemicals.

The best solution for water treatment in mobile plants

Graphical example of the system

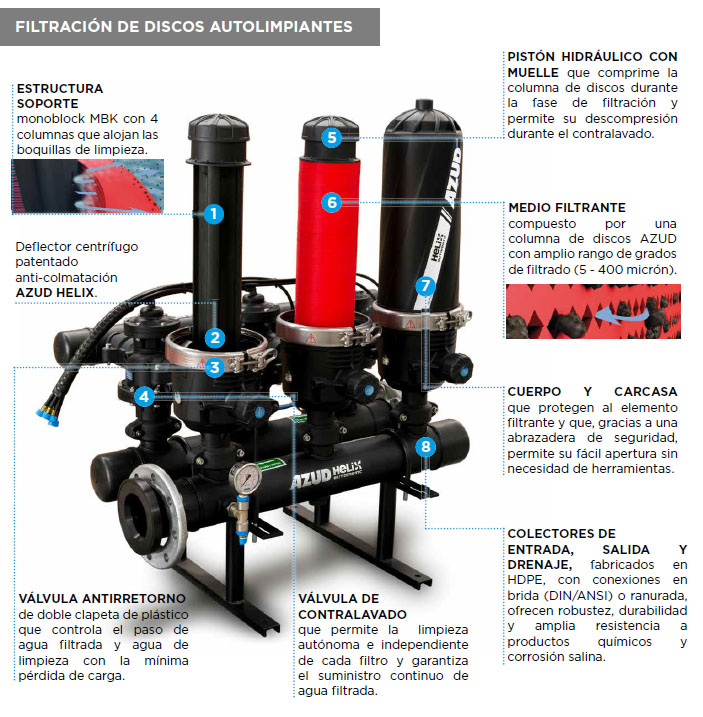

More technical information on disc filters:

Brand success stories

Filter for CFE cooling towers

Year: 2016

Production 800 m3/h (3522.3 gallons per minute)

Source of water: Cooling system circuit

Filtration degree: 130 microns

System used: 5 filters Azud Helix Automatic 210/6FX AA

One of the largest electric utilities in Latin America had 5 water cooling systems that suffered heat transfer losses of up to 30% due to the accumulation of small particles and for which the customer had to apply a high amount of biocide.

His strong ecological awareness and the accumulated expense, motivated him to rely on AZUD to put an end to his situation, installing 5 sidestream disc filtration units capable of providing a maximum of 800 m3/h for the different cooling equipment.

EMPOWER Dubai

Year: 2016

Production 2600 m3/h (11,479 gallons per minute)

Water source: Condenser water

Filtration degree: 20 microns

System used: 12 filters Azud Helix Automatic 4DC7

A large shopping mall in Dubai wanted to improve the performance of its air-conditioning system (ACS) and protect it from dust and sand particles entering the open circuit from the environment.

The solution offered by AZUD was a sidestream filtration system, which ensures the complete removal of 98% of suspended particles in the water, generating a reduction in energy consumption, guaranteeing the stability of the target temperature within the design range.

Filter for Mozyr Refinery Cooling Towers

- Country: Belarus

- Sector of activity: Oil/Gas Industry

- End User: Mozyr Refinery

- Application: Cooling tower cooling system protection

- Product: AZUD HELIX AUTOMATIC FT200 AA DLP

- Flow rate (m3/h): 320