Description

Softeners, also called softeners, are intended to remove hardness (hard water). This means that the calcium and magnesium, which produce the hardness, will be almost completely removed from the water to be treated.

Water softening is carried out by means of cation exchange resins that replace calcium and magnesium in water with sodium ions. For this purpose, they require regeneration with salt (industrial or pellet, with a purity equal to or greater than 99.2%) to recover their exchange capacity.

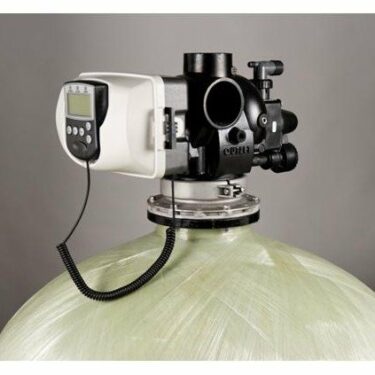

Twin softeners are ready to assemble and install packages consisting of a fiberglass tank, one or two automatic valves with top-mounted meter, interconnected by an alternating valve, a distributor and internal manifold per tank, cation resin, gravel and support and a brine tank (for regeneration salt) with suction system.

The twin line of domestic-commercial softeners is intended to treat water with a low to medium hardness content, less than 200 mg/L.

The twin STD capacity softeners, for commercial and industrial use, can treat water with hardness greater than 200 mg/L very efficiently.

Operating conditions:

- System operating pressure: 20 to 100 psi.

- Max. operating temperature: 49 °C.

- Feed water:

- Prefiltration: 5 ?m

- Inlet pH: 6.0 – 10.0

- Free chlorine: < 0.5 mg/L

- Turbidity: < 5.0 NTU

Domestic – commercial twin softeners:

Code |

Tank size (in) |

Resin volume (ft3) |

Design capacity (gr hardness) |

Salt to regenerate (lb salt) |

Maximum capacity (gr hardness) |

Salt to regenerate (lb salt) |

Minimum service flow (gpm) |

Maximum service flow (gpm) |

Backwash flow (gpm) |

Automatic valve |

|---|---|---|---|---|---|---|---|---|---|---|

P_640072 |

8×44 |

0.75 |

15000 |

5.6 |

21000 |

11.3 |

1.5 |

3.8 |

1.75 |

WS1TT |

P_640074 |

9×48 |

1 |

20000 |

7.5 |

28000 |

15 |

2 |

5 |

2.2 |

WS1TT |

P_640076 |

10×54 |

1.5 |

30000 |

11.3 |

42000 |

22.5 |

3 |

7.5 |

2.75 |

WS1TT |

P_640078 |

12×52 |

2 |

40000 |

15 |

56000 |

30 |

4 |

10 |

4 |

WS1TT |

P_640080 |

13×54 |

2.5 |

50000 |

18.8 |

70000 |

37.5 |

5 |

12.5 |

4.6 |

WS1TT |

P_640082 |

14×65 |

3 |

60000 |

22.5 |

84000 |

45 |

6 |

15 |

5.5 |

WS1TT |

P_640084 |

16×65 |

4 |

80000 |

30 |

112000 |

60 |

8 |

20 |

7 |

WS1TT |

P_640086 |

18×65 |

5 |

100000 |

37.5 |

140000 |

75 |

10 |

25 |

9 |

WS1TT |

P_640088 |

21×62 |

7 |

140000 |

52.5 |

196000 |

105 |

14 |

35 |

12 |

WS1.5EE |

P_640090 |

24×72 |

9 |

180000 |

67.5 |

252000 |

135 |

18 |

45 |

15.5 |

WS1.5EE |

P_640092 |

30×72 |

15 |

300000 |

112.5 |

420000 |

225 |

30 |

75 |

20 |

WS2EE/QC |

P_640094 |

36×72 |

20 |

400000 |

150 |

560000 |

300 |

40 |

100 |

28 |

WS2EE/QC |

P_640096 |

42×72 |

30 |

600000 |

225 |

840000 |

450 |

60 |

150 |

38.5 |

WS3 |

P_640098 |

48×72 |

40 |

800000 |

300 |

1120000 |

600 |

80 |

200 |

50.3 |

WS3 |

P_640100 |

63×83 |

62 |

1240000 |

465 |

1736000 |

930 |

124 |

310 |

87 |

WS3 |

Twin STD capacity softeners, commercial – industrial:

Code |

Tank size (in) |

Resin volume (ft3) |

Design capacity (gr hardness) |

Salt to regenerate (lb salt) |

Maximum capacity (gr hardness) |

Salt to regenerate (lb salt) |

Minimum service flow (gpm) |

Maximum service flow (gpm) |

Backwash flow (gpm) |

Automatic valve |

|---|---|---|---|---|---|---|---|---|---|---|

P_640071 |

8×44 |

0.75 |

16875 |

5.6 |

22875 |

11.3 |

1.5 |

3.8 |

1.75 |

WS1TT |

P_640073 |

9×48 |

1 |

22500 |

7.5 |

30500 |

15 |

2 |

5 |

2.2 |

WS1TT |

P_640075 |

10×54 |

1.5 |

33750 |

11.3 |

45750 |

22.5 |

3 |

7.5 |

2.75 |

WS1TT |

P_640077 |

12×52 |

2 |

45000 |

15 |

61000 |

30 |

4 |

10 |

4 |

WS1TT |

P_640079 |

13×54 |

2.5 |

56250 |

18.8 |

76250 |

37.5 |

5 |

12.5 |

4.6 |

WS1TT |

P_640081 |

14×65 |

3 |

67500 |

22.5 |

91500 |

45 |

6 |

15 |

5.5 |

WS1TT |

P_640083 |

16×65 |

4 |

90000 |

30 |

122000 |

60 |

8 |

20 |

7 |

WS1TT |

P_640085 |

18×65 |

5 |

112500 |

37.5 |

152500 |

75 |

10 |

25 |

9 |

WS1TT |

P_640087 |

21×62 |

7 |

157500 |

52.5 |

213500 |

105 |

14 |

35 |

12 |

WS1.5EE |

P_640089 |

24×72 |

9 |

202500 |

67.5 |

274500 |

135 |

18 |

45 |

15.5 |

WS1.5EE |

P_640091 |

30×72 |

15 |

337500 |

112.5 |

457500 |

225 |

30 |

75 |

20 |

WS2EE/QC |

P_640093 |

36×72 |

20 |

450000 |

150 |

610000 |

300 |

40 |

100 |

28 |

WS2EE/QC |

P_640095 |

42×72 |

30 |

675000 |

225 |

915000 |

450 |

60 |

150 |

38.5 |

WS3 |

P_640097 |

48×72 |

40 |

900000 |

300 |

1220000 |

600 |

80 |

200 |

50.3 |

WS3 |

P_640099 |

63×83 |

62 |

1395000 |

465 |

1891000 |

930 |

124 |

310 |

87 |

WS3 |

Calculation of the softener capacity:

Water hardness is usually expressed in mg/l CaCO3, also known as parts per million (ppm), but can also be expressed in other units, such as grains per gallon (gpg), 1 gpg = 17.1 mg/L or 17.1 ppm.

To calculate the volume of water that your equipment will be able to soften, you must know the hardness of the water to be treated in gpg and the capacity of the softener, which is directly related to the salt with which the equipment is regenerated.

In the specifications table, there are two columns, one for design capacity and the other for maximum capacity, expressed in grams of hardness per unit. Each one specifies the salt with which the resin must be regenerated to obtain this capacity.

Once the size of the equipment has been selected, the value of the equipment capacity (in gr) is taken and divided by the water hardness (in gpg). The result is the amount of gallons of water the equipment can treat before saturation. When consumption is not variable, this flow can be transformed into days by dividing the number of gallons that can be treated by the consumption per day.