Description

Standard capacity automatic water softeners:

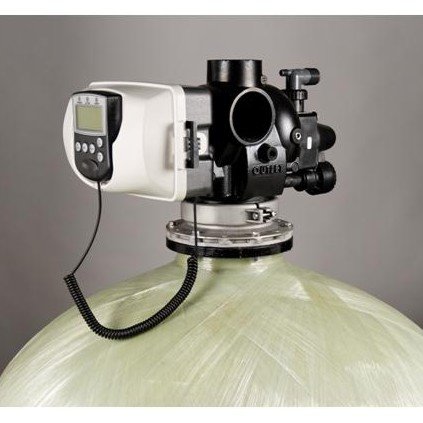

Simple automatic time-controlled water softeners with digital Clack valve: single-tank equipment with cationic resin, with manual or automatic control valve for time-controlled regeneration (regenerates every certain number of days or on a certain day of the week). Recommended for domestic, commercial or industrial use, with non-variable consumption and operation of less than 22 h.

Advantages of water softeners:

- Reduction of tartar formation, which causes stains and incrustations on crockery, cutlery, bathroom and kitchen furniture.

- Savings in soap and fabric softener consumption.

- Reduction of hair and skin dryness.

- Prevents scaling in heat exchange systems

- Prevents clogged pipes.

- Prevents fouling of reverse osmosis membranes.

- Water conditioning for specific processes and industrial machinery.

Operating conditions:

- System operating pressure: 20 to 100 psi.

- Max. operating temperature: 49 °C.

- Feed water:

- Prefiltration: 5 microns

- Inlet pH: 6.0 – 10.0

- Free chlorine: < 0.5 mg/L

- Turbidity: < 5.0 NTU

This line is available from 8×44″ to 63×83″ tanks, to treat from 1.5 to 310 GPM of instantaneous flow.

Models:

Automatic time-controlled water softeners (digital valve with timer)

Code |

Tank size (in) |

Resin volume (ft3) |

Design capacity (gr hardness) |

Salt to regenerate (lb salt) |

Maximum capacity (gr hardness) |

Salt to regenerate (lb salt) |

Minimum service flow (gpm) |

Maximum service flow (gpm) |

Backwash flow (gpm) |

Automatic valve |

|---|---|---|---|---|---|---|---|---|---|---|

P_640011 |

8×44 |

0.75 |

16,875 |

5.6 |

22,875 |

11.3 |

1.5 |

3.8 |

1.75 |

WS1TC |

P_640013 |

9×48 |

1.00 |

22,500 |

7.5 |

30,500 |

15.0 |

2.0 |

5.0 |

2.20 |

WS1TC |

P_640015 |

10×54 |

1.50 |

33,750 |

11.3 |

45,750 |

22.5 |

3.0 |

7.5 |

2.75 |

WS1TC |

P_640017 |

12×52 |

2.00 |

45,000 |

15.0 |

61,000 |

30.0 |

4.0 |

10.0 |

4.00 |

WS1TC |

P_640019 |

13×54 |

2.50 |

56,250 |

18.8 |

76,250 |

37.5 |

5.0 |

12.5 |

4.60 |

WS1TC |

P_640021 |

14×65 |

3.00 |

67,500 |

22.5 |

91,500 |

45.0 |

6.0 |

15.0 |

5.50 |

WS1TC |

P_640023 |

16×65 |

4.00 |

90,000 |

30.0 |

122,000 |

60.0 |

8.0 |

20.0 |

7.00 |

WS1.25TC |

P_640025 |

18×65 |

5.00 |

112,500 |

37.5 |

152,500 |

75.0 |

10.0 |

25.0 |

9.00 |

WS1.25TC |

P_640027 |

21×62 |

7.00 |

157,500 |

52.5 |

213,500 |

105.0 |

14.0 |

35.0 |

12.00 |

WS1.5EE |

P_640029 |

24×72 |

9.00 |

202,500 |

67.5 |

274,500 |

135.0 |

18.0 |

45.0 |

15.50 |

WS1.5EE |

P_640031 |

30×72 |

15.00 |

337,500 |

112.5 |

457,500 |

225.0 |

30.0 |

75.0 |

20.00 |

WS2EE/QC |

P_640033 |

36×72 |

20.00 |

450,000 |

150.0 |

610,000 |

300.0 |

40.0 |

100.0 |

28.00 |

WS2EE/QC |

P_640035 |

42×72 |

30.00 |

675,000 |

225.0 |

915,000 |

450.0 |

60.0 |

150.0 |

38.50 |

WS3 |

P_640037 |

48×72 |

40.00 |

900,000 |

300.0 |

1,220,000 |

600.0 |

80.0 |

200.0 |

50.30 |

WS3 |

P_640039 |

63×83 |

62.00 |

1,395,000 |

465.0 |

1,891,000 |

930.0 |

124.0 |

310.0 |

87.00 |

WS3 |

To select the most suitable water softener for your needs, you must know the maximum flow rate required. If you have any doubts about the selection, please contact one of our consultants.

Automatic water softeners by flow rate (digital valve with meter)

Code |

Tank size (in) |

Resin volume (ft3) |

Design capacity (gr hardness) |

Salt to regenerate (lb salt) |

Maximum capacity (gr hardness) |

Salt to regenerate (lb salt) |

Minimum service flow (gpm) |

Maximum service flow (gpm) |

Backwash flow (gpm) |

Automatic valve |

|---|---|---|---|---|---|---|---|---|---|---|

P_640041 |

8×44 |

0.75 |

16,875 |

5.6 |

22,875 |

11.3 |

1.5 |

3.8 |

1.75 |

WS1EE |

P_640043 |

9×48 |

1.00 |

22,500 |

7.5 |

30,500 |

15.0 |

2.0 |

5.0 |

2.20 |

WS1EE |

P_640045 |

10×54 |

1.50 |

33,750 |

11.3 |

45,750 |

22.5 |

3.0 |

7.5 |

2.75 |

WS1EE |

P_640047 |

12×52 |

2.00 |

45,000 |

15.0 |

61,000 |

30.0 |

4.0 |

10.0 |

4.00 |

WS1EE |

P_640049 |

13×54 |

2.50 |

56,250 |

18.8 |

76,250 |

37.5 |

5.0 |

12.5 |

4.60 |

WS1EE |

P_640051 |

14×65 |

3.00 |

67,500 |

22.5 |

91,500 |

45.0 |

6.0 |

15.0 |

5.50 |

WS1EE |

P_640053 |

16×65 |

4.00 |

90,000 |

30.0 |

122,000 |

60.0 |

8.0 |

20.0 |

7.00 |

WS1.25EE |

P_640055 |

18×65 |

5.00 |

112,500 |

37.5 |

152,500 |

75.0 |

10.0 |

25.0 |

9.00 |

WS1.25EE |

P_640057 |

21×62 |

7.00 |

157,500 |

52.5 |

213,500 |

105.0 |

14.0 |

35.0 |

12.00 |

WS1.5EE |

P_640059 |

24×72 |

9.00 |

202,500 |

67.5 |

274,500 |

135.0 |

18.0 |

45.0 |

15.50 |

WS1.5EE |

P_640061 |

30×72 |

15.00 |

337,500 |

112.5 |

457,500 |

225.0 |

30.0 |

75.0 |

20.00 |

WS2EE/QC |

P_640063 |

36×72 |

20.00 |

450,000 |

150.0 |

610,000 |

300.0 |

40.0 |

100.0 |

28.00 |

WS2EE/QC |

P_640065 |

42×72 |

30.00 |

675,000 |

225.0 |

915,000 |

450.0 |

60.0 |

150.0 |

38.50 |

WS3 |

P_640067 |

48×72 |

40.00 |

900,000 |

300.0 |

1,220,000 |

600.0 |

80.0 |

200.0 |

50.30 |

WS3 |

P_640069 |

63×83 |

62.00 |

1,395,000 |

465.0 |

1,891,000 |

930.0 |

124.0 |

310.0 |

87.00 |

WS3 |

For the selection of the softener you must know the maximum flow you require. If you have any doubts about the selection, please contact one of our consultants.

Calculation of water softener capacity:

Water hardness is usually expressed in mg/l CaCO3, also known as parts per million (ppm), but can also be expressed in other units, such as grains per gallon (gpg), 1 gpg = 17.1 mg/L or 17.1 ppm.

To calculate the amount of water your device can soften, it is necessary to know the hardness of the water to be treated in grains per gallon and the capacity of the softener, which is directly related to the salt used to regenerate the device.

In the specification table there are two columns, one for design capacity and one for maximum capacity, expressed in grams of hardness per device. All have specified the salt with which the resin must be regenerated to achieve this capability.

After selecting the device size, the value of the device capacity (in g) is taken and divided by the water hardness (in gpg). The result is the number of gallons of water the device can process before it becomes saturated. If consumption is not variable, this flow rate can be converted to days by dividing the number of gallons that can be treated by the consumption per day.

More information on water softeners:

Glossary of water treatment terms

Source: https://es.wikipedia.org/wiki/Descalcificador_de_agua