Description

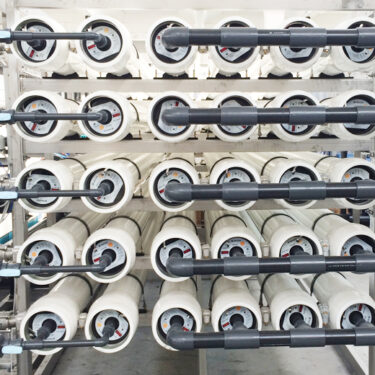

Industrial reverse osmosis.

Industrial reverse osmosis for applications in production lines, hotels, water purification plants, drinking water treatment plants and seawater desalination plants.

| Pipe connection diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| MODEL | CAPACITY GPM | NUMBER OF MEMBRANES | ARRANGEMENT | RECOVERY | NUMBER OF SEDIMENT FILTERS | ENGINE (HP) | FOOD | PERMEADO | REJECTION |

| CATM-2R3M | 20 – 30 | 6 | 1:1 | 60-75% | 1 | 10 | 2″ | 1 1/2″ | 1 1/2″ |

| CATM-3R3M | 35 – 45 | 9 | 1:01:01 | 60-75% | 1 | 20 | 2″ | 1 1/2″ | 1 1/2″ |

| CATM-3R4M | 45 – 60 | 12 | 1:01:01 | 60-75% | 1 | 20 | 2 1/2″ | 2″ | 1 1/2″ |

| CATM-3R5M | 60 -75 | 15 | 2:1 | 60-75% | 1 | 30 | 3″ | 2″ | 2″ |

| CATM-4R4M | 65 – 80 | 16 | 2:2 | 60-75% | 1 | 30 | 3″ | 2″ | 2″ |

| CATM-3R6M | 75 – 90 | 18 | 2:1 | 60-75% | 1 | 30 | 3″ | 2 1/2″ | 2″ |

| CATM-4R5M | 80 – 100 | 20 | 2:2 | 60-75% | 2 | 30 | 3″ | 2 1/2″ | 2″ |

| CATM-5R4M | 80 – 100 | 20 | 3:2 | 60-75% | 2 | 30 | 3″ | 2 1/2″ | 2″ |

| CATM-4R6M | 95 – 120 | 24 | 2:2 | 60-75% | 2 | 30 | 4″ | 2 1/2″ | 2″ |

| CATM-5R5M | 100 – 125 | 25 | 3:2 | 60-75% | 2 | 50 | 4″ | 2 1/2″ | 2 1/2″ |

| CATM-5R6M | 120 -150 | 30 | 3:2 | 60-75% | 3 | 50 | 4″ | 3″ | 2 1/2″ |

| CATM-6R5M | 120 – 150 | 30 | 3:02:01 | 60-75% | 3 | 50 | 4″ | 3″ | 2 1/2″ |

| CATM-6R6M | 145 – 180 | 36 | 4:2 | 60-75% | 3 | 60 | 4″ | 3″ | 3″ |

| CATM-7R6M | 170 – 210 | 42 | 4:3 | 60-75% | 4 | 75 | 6″ | 4″ | 3″ |

| CATM-8R6M | 195 – 240 | 48 | 5:3 | 60-75% | 4 | 75 | 6″ | 4″ | 4″ |

| CATM-9R6M | 220 -270 | 54 | 5:4 | 60-75% | 4 | 75 | 6″ | 4″ | 4″ |

| CATM-10R6M | 240 – 300 | 60 | 6:4 | 60-75% | 5 | 50 (2) | 6″ | 4″ | 4″ |

* gpm (gallons per minute) gpd (gallons per day) lpd (liters per day)

Industrial reverse osmosis applications:

- Drinking water purification

- Pharmaceutical Industry

- Hotels

- Medical use

- Water demineralization

- Laboratories

- Water for industrial processes

Characteristics:

- Expandable systems

- Hydranautics or LG high rejection membranes

- Codeline Pentair Diaphragm Holders

- Stainless steel horizontal multistage pump

- 1 micron disposable polishing cartridge pre-filters

- 3 rotameter type flowmeters (2 with valve)

- Low inlet pressure switch

- Control panel in industrial cabinet with contactor and motor guard

- 4 glycerin pressure gauges with stainless steel case

- Stainless steel globe type pressure control valve

- Automatic flush valve

- Double union ball type inlet valve

- PVC C80 pipes and fittings

- Fast&Tite thermoplastic tubing,

- Carbon steel structure with electrostatic baked-on paint finish

- Typical operating pressure 160-200 psi and maximum pressure 225 psi nominal ion rejection 98%.

- Standard three-phase voltage 220V (3 lines and 1 neutral) 60 Hz.

Operating parameters

- Reduces total dissolved solids (TDS): 98 to 99.5%.

- SDI (sediment density index) in feed water: < 5.0 Turbidity: < 1.0 NTU.

- Minimum inlet pressure: 40 to 60 psi.

- Operating pressure: 150 to 240 psi.

- Design temperature: 15 °C (59 °F).

- Operating temperature: 15 to 25 °C (59 to 77 °F).

- Feed water quality: < 2000 ppm TDS. pH: 2 to 11.

Inlet water specifications:

- Maximum temperature 30°C

- Maximum inlet pressure 80 psi

- Maximum operating pressure 240 psi

- Maximum hardness of 10 gr/gal or 170 mg/l.

- Maximum silica concentration: 25 ppm @ 50% recovery.

- pH range 3 – 11

- Maximum incoming TDS (total dissolved solids) of 1500 ppm. *Some brands specify 2000 mg/l.

- Langelier Saturation Index (LSI): 0.5 maximum although 0.0 (max) is preferable.

- Turbidity: 1 NTU maximum

- Iron: 0.1 mg/l maximum

- Manganese: 0.05 mg/l max.

- Remove hydrogen sulfide.

- Does not tolerate free chlorine or oxidants.

PRETREATMENT

- If the hardness exceeds 10 gr/gal, softener is recommended.

- If the silica content is high, it is necessary to inject an antiscalant. It does not affect the product water because it does not pass through the osmosis membrane.

- If the iron or manganese content is high, a suitable catalyst (Katalox Light, Green sand plus, or Z-OX) is required.

- If the water contains chlorine, it must be dechlorinated with activated carbon.

Also available:

Stainless steel structure, pump and membrane holder, product and/or feed TDS monitor, antifouling chemical dosing system, bypass system (filtered water mixing).

Industrial reverse osmosis is an assembled package ready to be installed at the place of use.