Activated carbon: Which particle size range is best suited for which application?

Contrary to popular belief, the capacity of an activated carbon does not increase no matter how small its particle size is. This is due to the fact that, no matter how finely a coal is ground, its surface area practically does not increase (the surface area is at a molecular level that cannot be affected by mechanical methods). However, the kinetics (adsorption rate) does increase substantially with decreasing carbon particle size. This means that the smaller the particle size of a coal, the smaller beds are required to achieve a given performance.

When to choose a smaller particle size activated carbon?

On the other hand, the smaller the particle size of a granular coal, the greater the pressure drop and, therefore, the higher the cost to achieve flow through it. From the above it can be concluded that in all cases the smallest coal size should be used as long as the benefit of requiring a small bed is greater than the cost of circulating the fluid through the bed.

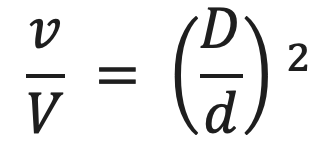

The increase in adsorption kinetics can be estimated with the following equation:

Where:

D = average particle diameter of the largest coal particle size

V = adsorption velocity of the largest carbon size

d = average particle diameter of the smallest coal particle size

v = adsorption velocity of the smallest carbon size

Guide to typical activated carbon sizes used by applications

4×10 Gas or air treatment. (Coconut shell).

6×12 and 8×16 Gold and precious metal recovery. (Coconut shell).

8×30 and 12×40 Drinking water treatment at industrial or commercial level. (Coconut shell or minerals).

20×50 Small-scale water purification (domestic activated carbon cartridge or low flow rates). (Coconut shell or minerals).

14×35 Cartridge respirators (masks), (coconut shell).

Less than 50 mesh. Potable or surface water treatment. (Coconut shell or minerals).

Less than 100 mesh. Potable or surface water treatment. (Coconut shell or minerals).

Less than 200 mesh. Potable or surface water treatment. (coconut shell or minerals); discoloration of liquids (pine wood).

Less than 325 mesh. Potable or surface water treatment. (coconut shell or minerals); discoloration of liquids (pine wood).

Pellet 4 mm Gas treatment. (Coconut shell or minerals).

Pellet 2 mm Treatment of gases and liquids. (Coconut shell or minerals).

If you need to know more about the granulometry of an activated carbon or the measures of mesh number to millimeters you can consult the following article:

What is particle size?

Share:

If you need more information, please contact us.

Some products that may interest you

-

AA-3 Activated carbon to reduce color and flavor in tequila and other distilled spirits

Add to quote -

Micro K Coconut shell activated carbon

Add to quote -

Micro 4 LF Coconut shell activated carbon free of fines

Add to quote -

Megapol C – Wood powder activated carbon

Add to quote -

Megapol E – Wood powdered activated charcoal

Add to quote -

Micropol 4 200 – Coconut shell powdered activated carbon

Add to quote -

Mega – Wood granular activated carbon

Add to quote -

Gama L – Lignite coal mineral activated carbon

Add to quote