What are water filters?

To understand automatic filters for large flow rates or high-water flows, we must first understand that water filters are equipment that remove contaminants in water by different methods such as a physical barrier, a biological or chemical process. In water filtration, for this case we are going to refer to it as a physical barrier to retain water sediments for large water flows, and that can be used in an industrial process, irrigation or to be ingested by humans.

What is water flow?

The volume of water flowing through a river, pipe or canal at a given time and place is called flow rate.

The flow rate is calculated by the following formula: Q = V / t, where Q (flow rate), V (volume) and t (time). Volume is usually measured in liters times time in hours, minutes or seconds.

How is productivity measured?

The following methods are used to measure the flow rate:

Volumetric method: A method for measuring the flow of water in very small streams, a direct measurement of the time it takes to fill a vessel of known volume. Velocity/area method: this method is based on measuring the current average velocity and the channel cross section. A simple way to calculate velocity is to measure the time it takes for a floating object to travel a known distance.

Types of filters for large flow rates or high flow rates

Shelco Multi-Cartridge Filter

Shelco offers a line of cartridge hosings for industrial filters that are considered high purity, are made of stainless steel and are ideal for high flow industrial loads. They use between 7 to 12 standard 2.5″ x 30″ or 40″ long cartridges, depending on the filter housing.

Some of the benefits that these filters offer is:

- Which have connections up to 8″.

- They are compatible with different standard and special cartridge filters, between 7 and 12 cartridges.

- These multi-cartridges are specially manufactured depending on the customer’s needs.

- They are equipped with a swivel bolt lock and a lifting davit.

- Can operate at a maximum operating pressure of: 150 PSI (10 bar) @ 300 oF (149 oC)

Deep bed filters

Deep bed filtration is used to decrease the concentration of suspended solids, these filters have granular media that are used to retain particles.

This type of filters can be gravity or pressure operated, they are usually cylindrical in shape and vertical. They are made of polyethylene inside and fiberglass outside.

After a certain period of service deep bed filters need to be backwashed to expel the solids retained in the granular media, also to expand the granular media bed and avoid its cementation that can be caused by the leaking water.

The most commonly used granular media in deep bed filters are: anthracite, garnet and silica sand.

Finally, backwashing is essential for this equipment and consists of fluidizing the filter bed.

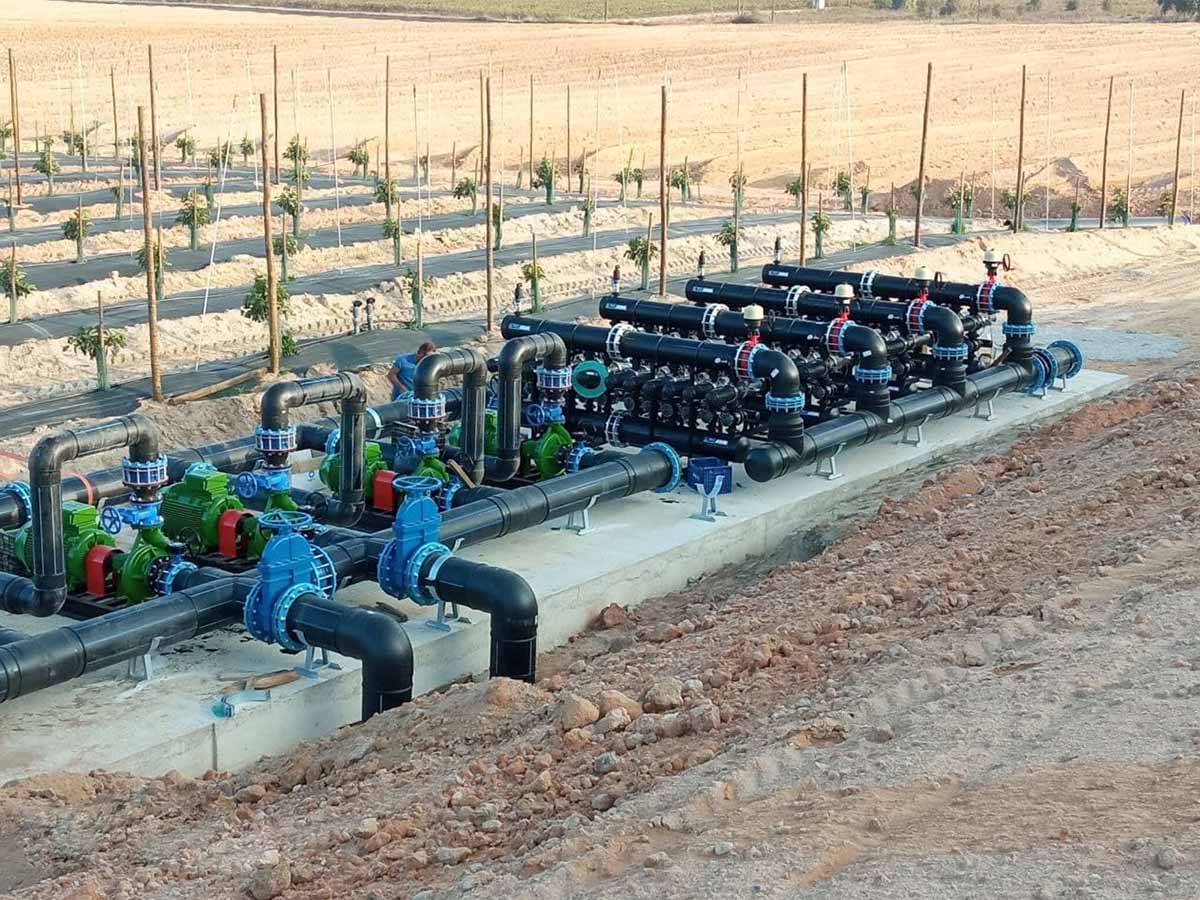

Disc filters

These filters were born as a proposal to filter water used in irrigation, and created for filtration of large flows of water in the field, and as it was used it was found applications in all areas that use water either industrial or services. These filters are a kind of variant of the basket strainers with a metal mesh.

The main function of these filters is to retain suspended solids using separate plastic discs that are placed one on top of the other.

How do disc filters for high flow rates work?

The discs used are ring-shaped so that when stacked they leave a gap in the center, each disc has grooves that each time you see are larger on its outer perimeter and narrower on its inner perimeter. The retention quality of this product depends not only on the size of the grooves but also on their geometry, angulation, intersections, length and quantity.

Water flows from the outside into the central channel and solids are retained depending on their size, making it unnecessary to clean the discs as frequently.

Advantages of disc filters

These filters use less water than conventional deep-bed filters, so in the long term we are talking about great savings in water, cleaning time and energy.

Its most common uses are for:

- Filtering drip irrigation effluents

- Filtering irrigation water

- Hydroponic systems

- Industrial filtration

- Filtration in water purification plants

- Pretreatment of softeners and reverseosmosis systems

- Water recirculation

- Cooling towers

- Replacing zeolite, anthracite or sand filters for water treatment

Conclusion

Automatic filters for large flows or high-water flows are variants of water filters that have sufficient capacity to withstand and filter high water flows, usually large flows are usually water coming from a river or somewhere with a lot of water pressure. In general, this type of filters is used for industrial work and have a long life span thanks to their resistant materials.